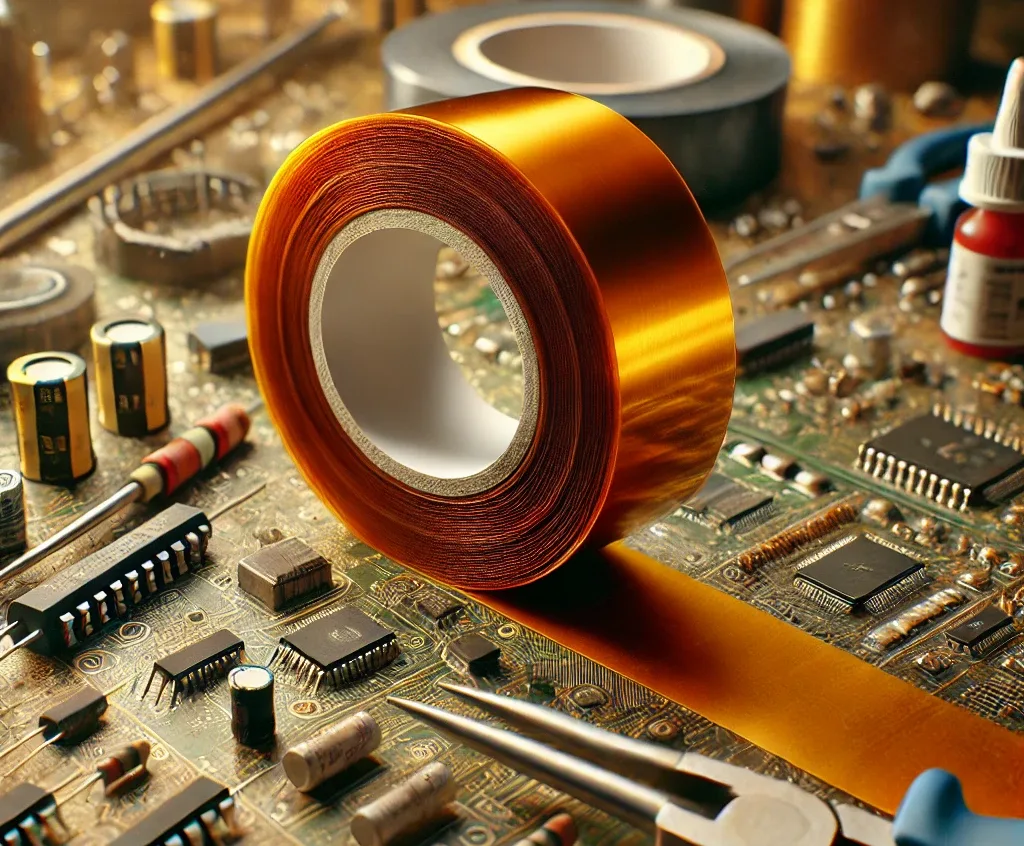

Use this guide to understand how conductive copper tape can benefit your projects

As electronic devices become increasingly compact and sophisticated, the demand for advanced conductive materials has never been higher. Conductive copper tape represents a versatile solution that can enhance electrical connectivity, provide electromagnetic shielding, and improve thermal management across various applications.

In 2025, the global conductive tape market has exceeded $2.8 billion, with copper-based solutions leading the charge in industries ranging from consumer electronics to automotive manufacturing. However, understanding the nuances between different types of conductive tapes and their optimal applications is crucial for making informed decisions.

To help you navigate this complex landscape, we’ve compiled a comprehensive analysis of conductive copper tape technology, focusing on the latest innovations in nano-carbon enhanced solutions.

Conductive Copper Tape Pros and Cons at a Glance

Pros

- Excellent electrical conductivity

- Superior thermal dissipation properties

- Easy application with self-adhesive backing

- Customizable dimensions and colors

- Anti-fingerprint surface treatment

- High-temperature resistance

- Reduces contact resistance in battery applications

- Improves overall device performance

Cons

- Higher upfront cost compared to standard tapes

- Requires proper storage conditions

- Limited shelf life (6 months optimal)

- Application technique affects performance

- May increase material costs for large-scale projects

- Surface preparation requirements

8 Key Advantages of Advanced Conductive Copper Tape

Understanding the benefits of modern conductive copper tape technology can help you make better decisions for your electronic projects. Here are 8 major advantages:

1.Superior Electrical Conductivity and Performance

Modern nano-carbon enhanced copper tapes offer exceptional electrical conductivity that surpasses traditional copper foil solutions. The integration of dispersed nano conductive graphite and carbon-coated particles creates a uniform conductive surface that effectively collects microcurrents from active materials.

This enhanced conductivity translates to improved signal integrity in electronic circuits and better power transmission efficiency in battery applications, making it an ideal choice for high-performance electronic devices.

2.Advanced Thermal Management Capabilities

Heat dissipation is critical in modern electronics, and advanced conductive copper tapes excel in this area. The nano-coating technology provides superior thermal conductivity, allowing for efficient heat transfer away from sensitive components.

This thermal management capability is particularly valuable in battery applications, where temperature control directly impacts performance, safety, and lifespan. The tape’s ability to dissipate heat while maintaining electrical connectivity makes it invaluable for compact electronic designs.

3.Reduced Contact Resistance and Improved Adhesion

One of the most significant advantages of nano-carbon enhanced copper tape is its ability to reduce contact resistance between positive and negative electrode materials. This reduction in resistance leads to more efficient current collection and improved overall system performance.

Additionally, the advanced adhesive system enhances bonding between different materials, reducing the need for additional binding agents and creating more reliable connections in critical applications.

4.Easy Application with Self-Adhesive Technology

The self-adhesive backing eliminates the need for additional mounting hardware or complex installation procedures. This feature significantly reduces installation time and labor costs while ensuring consistent application across various surfaces.

The acrylic adhesive system provides strong, durable bonds that maintain their integrity under various environmental conditions, making the tape suitable for both temporary and permanent installations.

5.Customization Options for Specific Applications

Modern conductive copper tapes offer extensive customization options, including various colors (with black being standard), thicknesses, and dimensions. This flexibility allows engineers to select the optimal specifications for their specific applications without compromising performance.

The ability to customize length and width ensures minimal waste and optimal coverage for projects of any scale, from small prototype development to large-scale manufacturing operations.

6.Enhanced Durability and Environmental Resistance

Advanced surface treatments provide multiple benefits beyond conductivity. Anti-fingerprint coatings maintain clean surfaces and prevent contamination, while high-temperature resistance ensures reliable performance in demanding environments.

The water and oil separation properties of the functional coating protect the conductive surface from environmental contaminants, extending the tape’s operational life and maintaining consistent performance over time.

7.Compliance with International Standards

Quality conductive copper tapes meet stringent international standards, including EU RoHS Directive compliance. This certification ensures that the materials are environmentally responsible and safe for use in consumer electronics and other applications.

Compliance with these standards also facilitates international trade and reduces regulatory complications for manufacturers working in global markets.

8.Versatile Application Across Multiple Industries

From battery manufacturing to screen production, conductive copper tape finds applications across numerous industries. Its versatility makes it a valuable solution for electronics manufacturers, research facilities, and repair services.

The tape’s ability to function effectively in diverse applications reduces inventory complexity and provides cost-effective solutions for businesses working across multiple product categories.

6 Potential Drawbacks of Conductive Copper Tape

While conductive copper tape offers numerous advantages, it’s important to consider potential limitations before implementation.

1.Higher Initial Investment Compared to Basic Tapes

Advanced nano-carbon enhanced copper tapes typically cost more than standard copper foil tapes. While the performance benefits often justify the additional expense, budget-conscious projects may need to carefully evaluate cost-benefit ratios.

However, the improved performance and reduced need for additional components often offset the higher initial cost through better system efficiency and reduced maintenance requirements.

2.Storage and Handling Requirements

Optimal performance requires specific storage conditions, including temperature control (25°C±5°C) and humidity management (60%±10%RH). These requirements may complicate inventory management and increase storage costs for some organizations.

Additionally, the six-month optimal usage window from shipment date requires careful inventory rotation to maintain peak performance characteristics.

3.Application Technique Sensitivity

Proper application technique is crucial for achieving optimal performance. Factors such as surface preparation, application pressure, and environmental conditions during installation can significantly impact the tape’s effectiveness.

Training personnel in proper application techniques may be necessary, particularly for critical applications where performance cannot be compromised.

4.Limited Shelf Life Considerations

The recommended six-month usage window from shipment date means that organizations must carefully manage inventory to avoid performance degradation. This limitation may require more frequent ordering and careful inventory management systems.

While the tape remains functional beyond six months, optimal performance characteristics may gradually decline, potentially affecting critical applications.

5.Surface Preparation Requirements

Achieving optimal adhesion and conductivity requires proper surface preparation, including cleaning and potentially treating the application surface. These additional steps can increase installation time and complexity.

Inadequate surface preparation can result in poor adhesion, reduced conductivity, and premature failure, making this step critical for successful implementation.

6.Thickness Limitations for Some Applications

At 0.08mm thickness, the tape may not be suitable for applications requiring thicker conductive layers or significant mechanical support. While this thickness is optimal for many applications, some specialized uses may require alternative solutions.

The ultra-thin profile, while advantageous for space-constrained applications, may not provide sufficient mechanical protection in high-stress environments.

Performance Comparison: Nano-Carbon Enhanced vs. Traditional Copper Tape

| Feature | Traditional Copper Tape | Nano-Carbon Enhanced Tape |

|---|---|---|

| Electrical Conductivity | Standard copper conductivity | Enhanced with nano-carbon particles |

| Thermal Performance | Basic heat dissipation | Advanced thermal management |

| Contact Resistance | Higher resistance | Significantly reduced resistance |

| Surface Treatment | Basic copper surface | Anti-fingerprint, high-temp coating |

| Adhesion Strength | Standard acrylic adhesive | Enhanced adhesive system |

| Environmental Resistance | Limited protection | Water/oil separation properties |

| Application Flexibility | Basic customization | Extensive customization options |

| Cost | Lower initial cost | Higher initial investment |

Applications and Use Cases

Battery Manufacturing and Management

Conductive copper tape plays a crucial role in modern battery technology, particularly in lithium-ion battery production. The tape’s ability to collect microcurrents and reduce contact resistance makes it essential for optimizing battery performance and extending operational life.

Electronic Screen Production

The tape’s anti-fingerprint properties and excellent conductivity make it ideal for touchscreen manufacturing and repair applications. The precise thickness control ensures consistent performance without interfering with screen sensitivity.

Electromagnetic Shielding

The conductive properties provide effective electromagnetic interference (EMI) shielding for sensitive electronic components, helping maintain signal integrity in complex electronic systems.

Prototype Development and Repair

The ease of application and removal makes conductive copper tape valuable for prototype development, testing, and field repairs where permanent solutions may not be practical.

Making the Right Choice for Your Project

When selecting conductive copper tape for your application, consider factors such as:

- Required conductivity levels

- Environmental conditions

- Temperature requirements

- Mechanical stress factors

- Budget constraints

- Installation complexity

For most applications requiring high-performance conductivity with advanced thermal management, nano-carbon enhanced copper tape provides superior value despite the higher initial cost.

Frequently Asked Questions

What is conductive copper tape used for? Conductive copper tape serves multiple purposes including electrical conductivity enhancement, electromagnetic shielding, thermal management, and creating electrical connections in various electronic applications.

What is the difference between conductive fabric tape and copper tape? Copper tape offers superior electrical conductivity and thermal properties, while fabric tapes may provide better flexibility and conformability but with lower conductivity performance.

Is copper tape real copper? Quality conductive copper tape contains genuine copper foil as the base material, often enhanced with additional conductive materials for improved performance.

Does Home Depot sell copper tape? While general retailers may carry basic copper tape, specialized high-performance variants like nano-carbon enhanced versions are typically available through industrial suppliers and specialized electronics distributors.

Conclusion

Advanced conductive copper tape technology represents a significant evolution in electrical connectivity solutions. While the initial investment may be higher than basic alternatives, the performance benefits, versatility, and reliability make it a worthwhile choice for demanding applications.

For projects requiring optimal electrical conductivity, thermal management, and long-term reliability, Fonitaniya‘s advanced copper tape solutions deliver the superior performance that justifies the investment. The enhanced system efficiency and reduced maintenance requirements these products provide make them an intelligent choice for engineers who refuse to compromise on quality.