The automotive industry continuously evolves, demanding increasingly sophisticated sealing solutions that can withstand extreme conditions while maintaining structural integrity. Among the most critical components in vehicle manufacturing and maintenance are door seals, which serve as the primary barrier against water infiltration, noise penetration, and environmental elements. The effectiveness of these seals largely depends on the quality of the adhesive tape used for their installation.

Understanding Automotive Door Seal Requirements

Modern vehicles face unprecedented challenges in terms of environmental exposure and performance expectations. Door seals must maintain their effectiveness across temperature ranges from -40°C to +120°C, resist humidity levels exceeding 95%, and withstand constant mechanical stress from door opening and closing cycles. Traditional adhesive solutions often fail under these demanding conditions, leading to premature seal failure, water damage, and costly warranty claims.

The automotive manufacturing process itself presents additional challenges. Assembly line speeds require adhesive solutions that can bond quickly and reliably without compromising long-term performance. Furthermore, the diverse range of materials used in modern door seals, including PP (polypropylene), EPDM (ethylene propylene diene monomer), TPV (thermoplastic vulcanizate), and TPE (thermoplastic elastomer), demands adhesive systems capable of forming strong bonds across multiple substrate types.

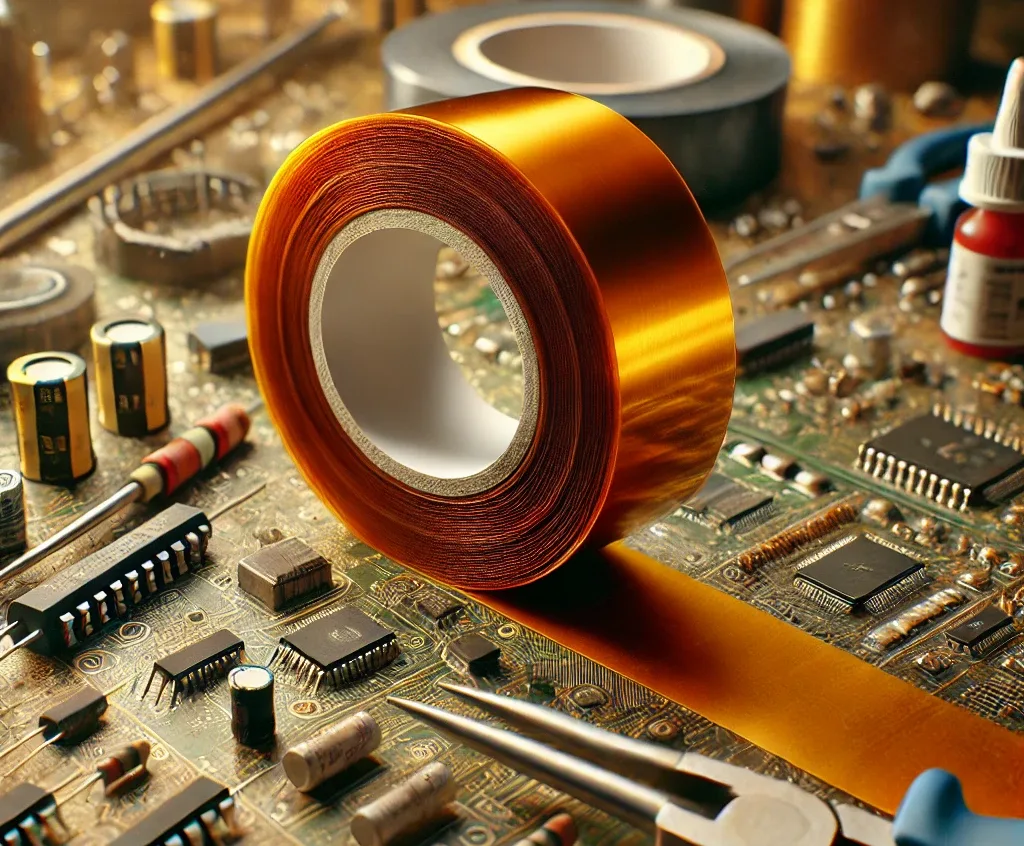

The Science Behind Acrylic Foam Adhesive Technology

Acrylic foam adhesive tapes represent a significant advancement in automotive bonding technology. Unlike traditional liquid adhesives or basic tape solutions, these products feature a closed-cell foam core structure that provides unique performance characteristics essential for automotive applications.

The foam core serves multiple functions simultaneously. Its viscoelastic properties enable the material to absorb and dissipate both static and dynamic loads, effectively compensating for thermal expansion and contraction cycles that would otherwise stress the bond line. This stress absorption capability is particularly crucial in automotive applications where temperature fluctuations can cause significant dimensional changes in both the vehicle structure and the seal material.

The closed-cell structure prevents water penetration through the adhesive layer, maintaining bond integrity even in high-humidity environments or direct water exposure. This characteristic is essential for door seal applications where moisture infiltration could compromise the entire sealing system.

Heat-Activatable Adhesive: Revolutionizing Installation Processes

One of the most significant innovations in automotive adhesive technology is the development of heat-activatable systems. These adhesives remain relatively inactive at room temperature, allowing for easy positioning and adjustment during installation. When subjected to elevated temperatures during the vehicle’s paint curing process or through targeted heating, the adhesive undergoes a chemical transformation that dramatically increases its bonding strength.

This technology offers several advantages over conventional adhesive systems. Installation errors can be corrected before activation, reducing waste and improving production efficiency. The heat activation process also ensures optimal adhesive flow and substrate wetting, resulting in stronger, more consistent bonds.

Substrate Compatibility and Primer-Free Application

Modern automotive door seals utilize a variety of materials, each presenting unique bonding challenges. Traditional adhesive systems often require multiple primer treatments to achieve adequate adhesion across different substrates, adding complexity and cost to the manufacturing process.

Advanced acrylic foam tapes are formulated to bond directly to automotive clearcoats and seal materials without primer application. This capability significantly simplifies the installation process while improving production safety by eliminating the need for potentially hazardous primer chemicals. The direct bonding capability also reduces the number of potential failure points in the adhesive system, improving overall reliability.

Performance Characteristics and Testing Standards

Automotive adhesive tapes must meet stringent performance requirements established by vehicle manufacturers and industry organizations. These standards address multiple performance aspects including initial adhesion strength, long-term durability, temperature resistance, and environmental compatibility.

| Performance Parameter | Standard Requirement | Advanced Acrylic Foam Tape |

|---|---|---|

| Temperature Resistance | -40°C to +120°C | Exceeds requirement |

| Humidity Resistance | 95% RH at 40°C | Superior performance |

| Peel Strength | >15 N/inch width | 20-25 N/inch width |

| Shear Strength | >500 hours at 80°C | >1000 hours at 80°C |

| Water Resistance | No bond degradation | Maintains 100% integrity |

Initial adhesion testing evaluates the immediate bond strength achieved upon application. However, automotive applications require consideration of long-term performance under service conditions. Accelerated aging tests simulate years of environmental exposure in compressed timeframes, ensuring that adhesive performance remains consistent throughout the vehicle’s service life.

Application Techniques and Best Practices

Proper application technique significantly influences the performance and longevity of automotive door seal installations. Surface preparation remains critical despite the primer-free nature of advanced adhesive tapes. Surfaces must be clean, dry, and free from contamination that could interfere with adhesive contact.

Temperature control during application affects both immediate handling characteristics and final bond strength. While these tapes can be applied at room temperature, optimal results are achieved when both the adhesive and substrate temperatures are maintained within specified ranges.

Pressure application ensures complete adhesive contact with the substrate surface. Insufficient pressure can result in air entrapment and reduced contact area, compromising bond strength. Rolling or pressing techniques should be employed to eliminate air bubbles and ensure uniform pressure distribution across the entire bond line.

Environmental Impact and Sustainability Considerations

The automotive industry increasingly prioritizes environmental sustainability, driving demand for adhesive solutions that minimize environmental impact throughout their lifecycle. Acrylic foam adhesive tapes offer several environmental advantages compared to traditional liquid adhesive systems.

Solvent-free formulations eliminate volatile organic compound (VOC) emissions during application and curing, improving workplace air quality and reducing environmental impact. The elimination of primer requirements further reduces chemical usage and associated environmental concerns.

The durability of acrylic foam adhesive systems contributes to sustainability by extending component service life and reducing the frequency of replacement operations. Longer-lasting door seals mean fewer warranty claims, reduced material consumption, and lower overall environmental impact.

Comparative Analysis: Standard vs. Advanced Adhesive Solutions

When evaluating adhesive options for automotive door seal applications, several key performance factors differentiate standard solutions from advanced acrylic foam systems.

| Feature | Standard Adhesive Tape | Advanced Acrylic Foam Tape |

|---|---|---|

| Temperature Range | Limited (-20°C to +80°C) | Extended (-40°C to +120°C) |

| Substrate Bonding | Requires primers | Direct adhesion |

| Water Resistance | Moderate | Excellent |

| Stress Absorption | Minimal | Superior viscoelastic properties |

| Installation Speed | Standard | Enhanced with heat activation |

| Long-term Durability | Good | Exceptional |

Standard adhesive tapes typically utilize basic acrylic or rubber-based adhesive systems that provide adequate performance under normal conditions but may fail when subjected to the extreme environments encountered in automotive applications. Temperature cycling, humidity exposure, and mechanical stress can cause premature bond failure, leading to seal displacement and water infiltration.

Advanced acrylic foam systems address these limitations through engineered material properties that maintain performance across extended temperature ranges and environmental conditions. The foam core structure provides inherent stress relief capabilities that prevent bond line failure due to differential thermal expansion.

Quality Assurance and Manufacturing Standards

Automotive adhesive tape manufacturing requires strict quality control measures to ensure consistent performance across production batches. Statistical process control techniques monitor critical parameters including adhesive thickness, foam density, and adhesion strength to maintain product specifications within tight tolerances.

ISO/TS 16949 automotive quality management standards govern production processes, ensuring that manufacturing operations meet automotive industry requirements for quality, reliability, and traceability. These standards mandate comprehensive testing protocols and documentation systems that enable full product traceability from raw materials to final application.

Incoming material inspection verifies that all components meet specification requirements before entering the production process. In-process monitoring ensures that manufacturing parameters remain within acceptable ranges throughout production. Final product testing validates that finished goods meet all performance specifications before release for shipment.

Economic Considerations and Cost-Benefit Analysis

While advanced acrylic foam adhesive tapes may command premium pricing compared to standard solutions, their superior performance characteristics often result in lower total cost of ownership when evaluated over the complete product lifecycle.

Reduced warranty claims represent a significant cost saving for vehicle manufacturers. Door seal failures requiring warranty service typically involve substantial labor costs for removal, cleaning, and reinstallation operations. The improved reliability of advanced adhesive systems dramatically reduces the frequency of these expensive service events.

Manufacturing efficiency improvements also contribute to cost savings. Primer-free application eliminates material costs, application time, and associated environmental compliance requirements. Heat-activatable systems allow for installation error correction before final bonding, reducing waste and rework costs.

Future Developments and Industry Trends

The automotive adhesive industry continues to evolve in response to changing vehicle technologies and environmental requirements. Electric vehicle adoption introduces new challenges including different thermal management requirements and the need for adhesive systems compatible with high-voltage electrical systems.

Autonomous vehicle development may influence adhesive requirements as vehicles experience different usage patterns and environmental exposures. Increased vehicle longevity expectations in shared mobility applications could drive demand for even more durable adhesive solutions.

Sustainability trends continue to influence product development, with increasing focus on bio-based raw materials and end-of-life recyclability. Future adhesive systems may incorporate renewable content while maintaining or improving performance characteristics.

Conclusion: Choosing the Right Solution

The selection of appropriate adhesive tape for automotive door seal applications requires careful consideration of performance requirements, application constraints, and long-term reliability expectations. While various options exist in the marketplace, advanced acrylic foam systems offer compelling advantages for demanding automotive applications.

For manufacturers seeking a reliable, high-performance solution that combines exceptional adhesion strength with environmental durability, products like the Fonitaniya Automotive Door Seal Adhesive Tape FON-10034 represent the current state-of-the-art in automotive bonding technology. Its heat-activatable adhesive system, primer-free application capability, and superior environmental resistance make it an ideal choice for modern vehicle manufacturing and service applications.