Did you know that effective thermal management can extend the lifespan of electric vehicle (EV) batteries by up to 30%? As EV adoption continues to rise, the demand for smarter, more efficient battery solutions has never been more critical. In this article, we will explore how advanced thermal management technologies are enhancing the performance and safety of electric vehicle batteries and how companies like Fonitaniya™ are leading the charge with innovative solutions.

Delivering Superior Solutions for EV Battery Insulation Pads

As electric vehicles become increasingly mainstream, original equipment manufacturers (OEMs) are challenged to meet rising expectations for reliability and extended range. Achieving these goals requires not only innovation in battery design but also advancements in material selection and manufacturing processes. At Fonitaniya™, we have a proven history of collaborating with OEMs to tackle these challenges by developing high-performance solutions that are both innovative and scalable.

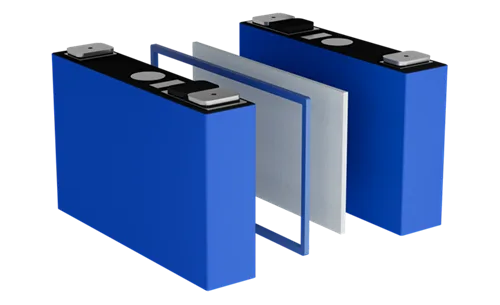

A prime example is our Anti-Thermal Propagation (ATP) pads, engineered specifically for use with prismatic battery cells. These pads incorporate built-in spacers that enhance thermal management, minimizing the risk of thermal runaway, which can compromise battery safety and longevity. Research from the International Journal of Thermofluids shows that effective thermal management reduces the likelihood of heat build-up, thereby improving battery performance and safety.

By leveraging our extensive industry knowledge and cross-sector expertise, Fonitaniya™ supports customers in creating safer, higher-performing EV batteries that not only enhance energy density but also provide competitive cost per kilowatt-hour outputs.

Innovative Material Applications to Enhance EV Performance

The shift towards electric vehicles presents unique challenges, compelling OEMs to strike a balance between innovation and scalability. They require materials that meet complex specifications while also being feasible for large-scale manufacturing. A recent report from McKinsey indicates that many components in EVs will remain analogous to those found in traditional internal combustion engine (ICE) vehicles. As a result, OEMs often ask, “How can we repurpose or adapt materials we have already specified?”

At Fonitaniya™, we prioritize designing for high-volume manufacturing, ensuring that our engineering teams contemplate scalability from the outset. Our bespoke solutions meet intricate technical requirements while also being suitable for mass production. This end-to-end support has cultivated a robust reputation within the automotive industry.

Innovatively applying existing materials in new ways allows OEMs to access scalable solutions within lean cost parameters. For example, the use of nano-enhanced fluids for lithiation in batteries exemplifies a specific material innovation that plays a critical role in thermal management. By ensuring optimal thermal transfer away from battery cells, we enable better performance during rapid heating and cooling cycles.

Moreover, adhesive materials facilitate the bonding of diverse components, such as aluminum, carbon fiber composites, and steel, ultimately enabling reduced vehicle weight and enhanced performance.

Leveraging Proven Cross-Sector Expertise to Drive EV Innovation

One of the significant advantages Fonitaniya™ offers is our ability to draw on cross-sector expertise. Our talented engineers collaborate across industries, including automotive, electronics, life sciences, and renewable energy. This interdisciplinary approach fosters innovative solutions that transcend traditional boundaries.

For instance, thermal management methodologies from the electronics sector have been successfully adapted for application in the EV industry. By experimenting with materials and techniques that have proven successful elsewhere, we empower our automotive clients to achieve their objectives more effectively. A collaborative engagement recently led to the implementation of enhanced thermal insulation systems in a major EV manufacturer’s battery packs, resulting in a 20% increase in thermal performance.

Related article: 4 applications of exterior automotive tape.

Surpassing Customer Expectations with Advanced Processes

Given the rise of various battery types—prismatic, cylindrical, and pouch cells—it becomes even more vital to utilize materials that cater to different requirements. Our encapsulated anti-thermal propagation pads for pouch cells exemplify how we combine advanced lightweight materials to create effective thermal barriers in EV battery systems.

We prioritize collaboration with our customers, believing it is essential for co-creating innovative solutions that meet their specifications and requirements effectively. Our state-of-the-art manufacturing facility in Huizhou is IATF certified, utilizing a combination of automated processes and continuous production techniques. This not only boosts efficiency but also ensures that we can deliver cost-competitive solutions tailored to our customer needs.

Conclusion

In conclusion, advanced thermal management is essential for optimizing electric vehicle battery performance, safety, and longevity. Fonitaniya Tape Companies has been an adhesive solution provider for over 15 years, specializing in thermal insulation pads and innovative materials for the automotive industry. As we continue to push the boundaries of what’s possible in thermal management, we remain committed to helping OEMs achieve their ambitious goals for electric vehicles. By combining cross-sector expertise with a focus on scalability, we ensure that our partners thrive as they navigate the evolving landscape of electric mobility.

FAQs

How does thermal management impact electric vehicle battery life?

Effective thermal management can enhance battery life by reducing overheating and optimizing energy efficiency.

What materials are commonly used in automotive tape for thermal management?

Automotive tape often uses advanced materials like closed-cell foam and adhesive technologies to enhance thermal performance.

Can enhancing thermal management improve EV range?

Yes, improving thermal management can optimize battery efficiency, directly contributing to extended range.

Why is collaboration important in automotive tape manufacturing?

Collaboration helps in co-creating tailored solutions that meet specific performance and safety requirements more efficiently.

What innovations are making waves in the thermal management space?

Innovations like nano-enhanced fluids and advanced adhesive technologies are revolutionizing thermal management in electric vehicles.