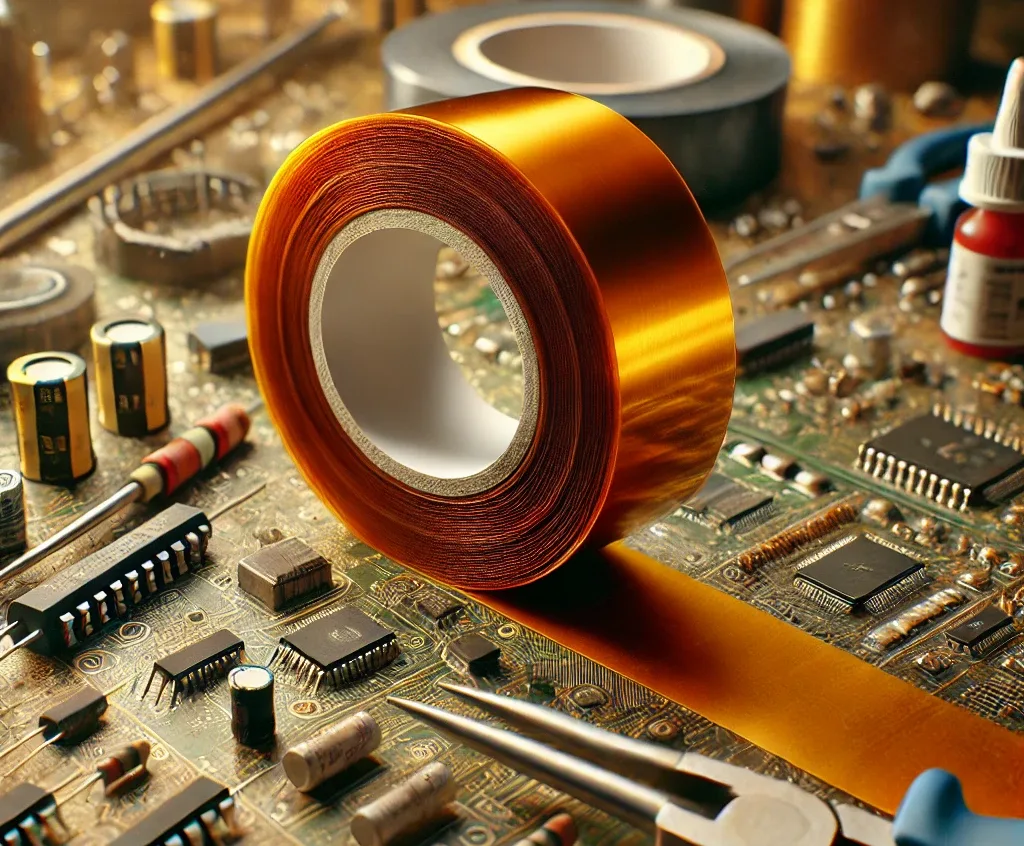

Aluminum foil tape is a versatile adhesive material designed to serve critical roles in high-performance environments. Its reflective surface, heat resistance, and strong bonding capability make it ideal for industries ranging from electronics and automotive to HVAC and construction.

But not all aluminum tapes are created equal. Among the various types available, metalized Mylar aluminum foil tape stands out for its superior durability, shielding performance, and resistance to harsh environmental factors. Understanding its core purposes—and how it compares to standard alternatives—can help professionals make informed choices for demanding applications.

Key Functions of Aluminum Foil Tape

1.Thermal Insulation and Heat Resistance

One of the primary purposes of aluminum foil tape is to withstand high temperatures. The aluminum layer reflects radiant heat, while the adhesive is engineered to remain stable and secure under thermal stress. This makes it suitable for sealing ductwork, insulating components, and protecting heat-sensitive areas in industrial systems.

2.EMI/RFI Shielding

Modern electronic devices require reliable protection from electromagnetic interference (EMI) and radio frequency interference (RFI). High-performance foil tapes—especially those with metalized Mylar laminate—offer effective shielding across a broad frequency spectrum, making them essential in applications such as circuit board isolation, cable bundling, and enclosure grounding.

3.Light Blocking

In precision electronics and optical systems, blocking light penetration is crucial. The reflective surface of metalized Mylar foil tape provides superior light-blocking performance compared to standard aluminum tape. This function helps ensure optimal operation in sensors, displays, and other light-sensitive components.

4.Environmental Sealing

In high-humidity or corrosive environments, ordinary tapes may degrade or peel. Metalized aluminum foil tapes excel in moisture and corrosion resistance, maintaining a strong, lasting seal even when exposed to water, chemicals, or fluctuating weather conditions. This makes them ideal for both indoor and outdoor use.

Comparison: Standard Foil Tape vs. Metalized Mylar Tape

| Feature | Standard Aluminum Foil Tape | Metalized Mylar Aluminum Tape |

|---|---|---|

| Heat Resistance | Moderate | High (suitable for extreme temps) |

| EMI/RFI Shielding | Basic shielding | Broad-spectrum, high-efficiency |

| Light Blocking | Partial | Excellent |

| Durability in Harsh Conditions | Limited | Strong moisture & corrosion resistance |

| Adhesive Strength | General-purpose | High-performance acrylic |

| Appearance & Reflectivity | Matte or semi-reflective | Sleek, highly reflective |

While standard foil tape is effective for general insulation and sealing, it may not offer the specialized performance needed in environments where electromagnetic shielding or long-term durability is critical. In contrast, metalized Mylar aluminum tape provides a more advanced, multi-functional solution, combining electrical protection with mechanical resilience.

Common Applications Across Industries

- Electronics: EMI shielding for components, connectors, and enclosures

- Automotive: Heat-resistant sealing in engine compartments and wiring harnesses

- HVAC: Duct insulation, sealing joints in high-temperature air systems

- Construction: Vapor barriers, moisture protection behind reflective insulation

- Industrial Manufacturing: Protecting sensitive equipment from heat, humidity, and EMI exposure

In all these sectors, using the right type of aluminum foil tape can enhance system reliability, reduce maintenance costs, and ensure regulatory compliance.

Final Thoughts

Choosing the right aluminum foil tape depends on your application’s specific demands. While conventional foil tapes serve basic insulation and sealing needs, advanced metalized Mylar tapes are engineered to deliver superior performance in harsh, high-temperature, and EMI-prone environments.

For professionals seeking long-lasting protection, excellent light-blocking capability, and effective EMI shielding, tapes like those offered by Fonitaniya provide an optimal balance of durability and technical performance.