Stair-related accidents account for thousands of injuries every year, making slip prevention a critical safety concern for both residential and commercial properties. Whether you’re dealing with wet conditions, smooth surfaces, or high-traffic areas, the right anti-slip solution can make the difference between a safe passage and a dangerous fall.

Understanding the Slip Hazard Problem

Slippery stairs pose significant risks in various environments. From rain-soaked outdoor steps to polished indoor staircases, the potential for accidents remains constant. The problem becomes even more pronounced in industrial settings where workers carry heavy loads or operate in challenging conditions.

The key to effective slip prevention lies in understanding traction mechanics. When foot meets surface, friction determines stability. Without adequate grip, even the most careful person can lose their footing, leading to potentially serious injuries.

How to Make Stair Treads Not Slippery: Proven Solutions

Surface Preparation and Cleaning

Before applying any anti-slip solution, thorough surface preparation is essential. Clean stairs with degreasing agents to remove oil, dirt, and debris that compromise adhesion. Allow surfaces to dry completely before proceeding with installation.

Choosing the Right Anti-Slip Method

Several approaches exist for creating non-slip stair surfaces:

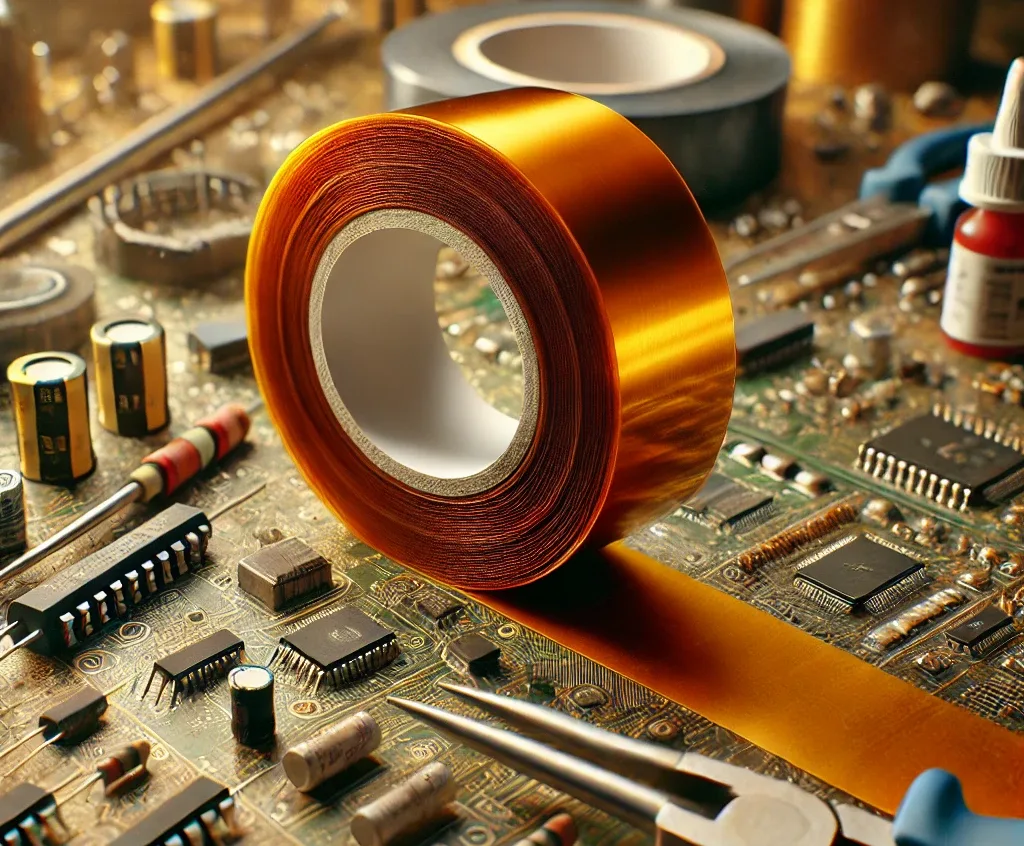

- Mineral-Coated Tapes: These provide excellent traction through abrasive surfaces that maintain grip even when wet. The mineral coating creates multiple contact points with footwear, significantly increasing friction coefficients.

- Textured Paints: While cost-effective, these solutions often wear down quickly under heavy traffic and may require frequent reapplication.

- Mechanical Treads: Metal or rubber treads offer durability but can be expensive and may not suit all architectural styles.

- Adhesive Strips: Modern pressure-sensitive adhesive strips combine ease of installation with reliable performance, making them popular for both residential and commercial applications.

Strategic Placement: Where to Put Anti-Slip Tape on Stairs

Proper placement is crucial for maximum effectiveness. The most critical areas include:

Leading Edge Coverage

Apply anti-slip tape along the front edge of each step, extending approximately 2-3 inches back from the nose. This positioning catches the foot during the most vulnerable moment of contact.

Full Tread Coverage

For high-risk environments, consider covering the entire tread surface. This approach provides comprehensive protection but requires more material and careful installation to avoid bubbling or lifting.

Landing Areas

Don’t overlook stair landings and transition zones. These areas often experience concentrated foot traffic and benefit from anti-slip treatment.

Width Considerations

Ensure tape width matches foot traffic patterns. Narrower installations may leave dangerous gaps, while overly wide applications can create unnecessary trip hazards.

Understanding Slip Resistance Ratings for Stairs

Slip resistance is measured using standardized testing methods that evaluate friction coefficients under various conditions.

ANSI/NFSI Standards

The American National Standards Institute and National Floor Safety Institute have established benchmarks for slip resistance. A coefficient of friction (COF) of 0.60 or higher is generally considered safe for level surfaces, while stairs may require higher ratings due to increased risk factors.

Wet vs. Dry Performance

Quality anti-slip products maintain performance in both wet and dry conditions. Look for solutions that have been tested under various environmental conditions to ensure consistent safety performance.

Testing Methods

Common testing includes the British Pendulum method and the ASTM D2047 standard, which simulate real-world walking conditions to provide reliable safety ratings.

Slip Resistance Comparison Table

| Surface Type | Dry COF | Wet COF | Durability Rating |

|---|---|---|---|

| Mineral-Coated Tape | 0.85+ | 0.75+ | Excellent |

| Standard Tape | 0.70 | 0.45 | Good |

| Textured Paint | 0.65 | 0.40 | Fair |

| Bare Metal | 0.30 | 0.15 | N/A |

Making Metal Stairs Safe: Special Considerations

Metal stairs present unique challenges due to their naturally smooth surfaces and tendency to become extremely slippery when wet. Environmental factors like temperature changes can also affect metal surface properties.

Surface Preparation for Metal

Metal surfaces require special attention during preparation. Use appropriate degreasers and ensure complete moisture removal. Some metals may benefit from light abrasion to improve adhesive bonding.

Thermal Expansion Concerns

Consider thermal expansion and contraction when applying anti-slip solutions to metal stairs. Choose products with flexible adhesives that can accommodate movement without losing bond strength.

Corrosion Prevention

Quality anti-slip tapes create a barrier between metal surfaces and environmental elements, potentially extending stair life by preventing moisture-related corrosion.

Product Performance Analysis

When evaluating anti-slip solutions, several factors determine long-term success:

Adhesive Technology

Industrial-grade pressure-sensitive adhesives provide superior bonding compared to standard options. These formulations resist moisture, temperature fluctuations, and mechanical stress while maintaining bond integrity over time.

Surface Composition

Mineral-coated surfaces offer advantages over synthetic alternatives. The natural abrasive properties provide consistent traction without the degradation common in rubber or plastic materials.

Profile Design

Low-profile designs minimize trip hazards while maintaining effectiveness. This balance is crucial in applications where aesthetics matter alongside safety performance.

Installation Best Practices

Successful installation requires attention to detail and proper technique:

Environmental Conditions

Install during optimal weather conditions when temperatures are moderate and humidity is low. Extreme temperatures can affect adhesive performance during the critical bonding period.

Application Technique

Remove backing paper gradually while applying firm pressure to eliminate air bubbles. Use a roller or similar tool to ensure complete contact across the entire surface.

Curing Time

Allow adequate curing time before subjecting the installation to foot traffic. Most quality products require 24-48 hours for full adhesive development.

Maintenance and Longevity

Regular maintenance extends anti-slip tape life and maintains safety performance:

Cleaning Protocols

Use appropriate cleaning methods that remove debris without damaging the anti-slip surface. Avoid harsh chemicals that might compromise adhesive bonds.

Inspection Schedule

Implement regular inspection routines to identify wear patterns or lifting edges before they become safety hazards. Replace sections showing significant wear or damage.

Traffic Pattern Analysis

Monitor high-wear areas and consider reinforcement or more frequent replacement in these zones to maintain consistent safety levels.

Application Versatility

Modern anti-slip solutions serve diverse applications beyond basic stair safety:

Industrial Environments

Warehouses, manufacturing facilities, and construction sites benefit from heavy-duty anti-slip solutions that withstand equipment traffic and harsh conditions.

Residential Applications

Home stairways, particularly those leading to basements or outdoor areas, require reliable slip prevention that complements interior design.

Transportation and Mobile Equipment

Vehicles, trailers, and mobile equipment often incorporate anti-slip surfaces to ensure operator safety during entry and exit procedures.

Cost-Benefit Analysis

Investing in quality anti-slip solutions provides significant returns through reduced liability, fewer accidents, and lower insurance premiums. The relatively modest upfront cost pales in comparison to potential accident-related expenses.

Initial Investment vs. Long-Term Value

Premium anti-slip products may cost more initially but offer superior durability and performance, ultimately providing better value through extended service life.

Liability Reduction

Proactive slip prevention demonstrates due diligence in safety management, potentially reducing legal exposure in case of accidents.

Product Comparison: Standard vs. High-Performance Solutions

When comparing anti-slip options, high-performance mineral-coated tapes offer significant advantages over standard alternatives:

Standard Anti-Slip Tape:

- Basic friction surface

- Limited durability under heavy traffic

- Moderate adhesive strength

- Suitable for light residential use

High-Performance Solution:

- Advanced mineral coating for superior traction

- Industrial-grade adhesive technology

- Extended durability even under heavy equipment traffic

- Suitable for demanding commercial and industrial applications

- Low-profile design minimizing trip hazards

- Multi-surface compatibility including challenging materials

The Fonitaniya™ Anti-Slip Tape for Stairs exemplifies this high-performance category, combining advanced materials engineering with practical design to deliver reliable, long-lasting safety solutions for any environment.