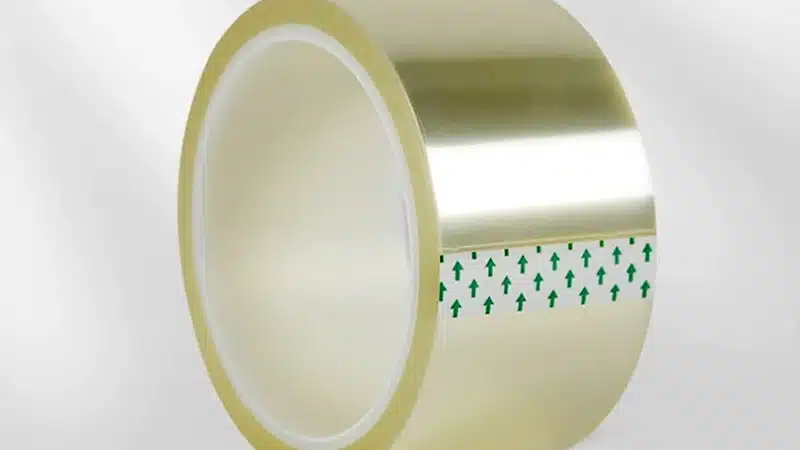

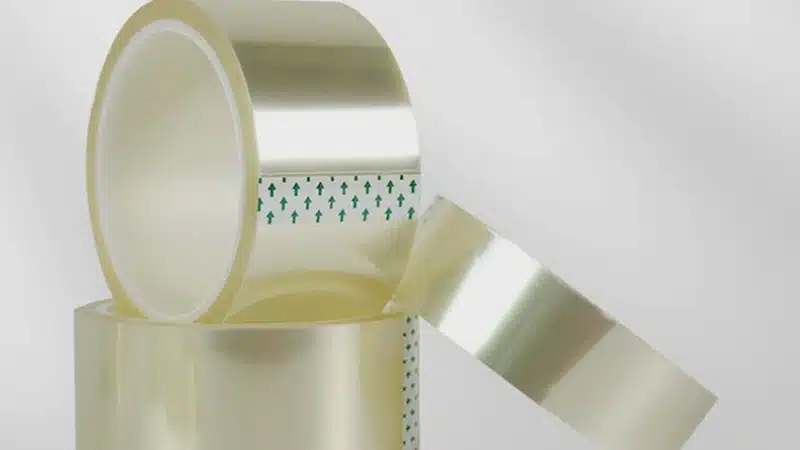

In solar panel manufacturing, BOPP Solar Tape for Lamination is a specialized adhesive film used to secure solar cells during lamination. It ensures cell alignment and protection throughout pressing and thermal curing, delivering clear visibility and stable bonding.

The Need for Specialized Solar Lamination Tape

Solar lamination demands a tape that:

- Offers transparent adhesion to enable inspection and alignment.

- Seals cells securely to avoid shifting under heat and pressure.

- Resists aging and handles high-temperature environments.

Generic tapes often lack these capabilities. Poor visibility, curling, inadequate adhesion, or brittleness can all lead to yield losses during lamination.

Key Benefits of BOPP Solar Tape for Lamination

- Exceptional Clarity

Crystal-clear BOPP backing enhances visibility, making cell alignment precise and inspection straightforward. - Strong Adhesion

Water-based acrylic adhesive locks solar cells firmly in place, reducing movement during lamination. - Durable and Flexible

With aging resistance and up to 90% elongation at break, this tape remains resilient under thermal cycling and mechanical stress. - User-Friendly Application

Designed to dispense without curling or distortion. Compatible with both manual and automated dispensers. - Environmentally Safe

Acid-free, solvent-free, and made from eco-friendly polypropylene foil. Withstands temperatures up to 150 °C, ideal for lamination conditions.

Product Overview: Fonitaniya™ BOPP Solar Tape (FON‑10023)

The Fonitaniya™ BOPP Solar Tape (FON‑10023) is engineered specifically for solar cell lamination.

| Feature | Description |

|---|---|

| Material | BOPP backing with water-based acrylic adhesive |

| Clarity | Crystal-clear visibility |

| Adhesion | Strong, cell-secure bond |

| Temperature Tolerance | Up to 150 °C |

| Durability | High elongation, aging resistance |

| Application | Manual or automatic, no curling |

This tape helps manufacturers improve panel quality, reduce defects, and streamline lamination processes.

How to Use the Tape

- Clean the solar cell surface thoroughly.

- Cut the tape to needed length.

- Apply directly to the cell surface, pressing firmly to activate the adhesive.

- Maintain consistent pressure during lamination to ensure full coverage.

- Continue with lamination; the tape remains stable under heat.

- After lamination, if needed, tape residue can be safely removed with minimal trace.

Comparison: BOPP Solar Tape vs. a Similar Lamination Solution

| Feature | BOPP Solar Tape | Other Lamination Tape |

|---|---|---|

| Clarity | Excellent transparency | Often opaque or tinted |

| Adhesion Strength | High, consistent | May weaken under heat |

| Curling | No curling during dispense | May curl or distort |

| Aging Resistance | High elongation, durable | Brittle over time |

| Temperature Tolerance | Up to 150 °C | Often lower |

| Chemical Safety | Acid/solvent-free | May contain solvents |

While both products serve the same purpose, BOPP Solar Tape stands out for clarity, environmental safety, and ease of handling.

FAQs About Solar Lamination Tape

Can other tapes be used for solar lamination?

Some film tapes exist, but they often lack required clarity, heat resistance, or adhesion.

Does the tape leave residue post-lamination?

High-quality BOPP tape leaves minimal residue; any remaining adhesive is easily removed.

Is this tape compatible with automated lamination?

Yes. Designed to feed smoothly without curling, ideal for roll-to-roll or speech applicators.

Is it safe for outdoor or long-term solar use?

Yes. As an acid-free, solvent-free material with high aging resistance, it aligns with sustainable standards.

Conclusion: Why BOPP Solar Tape for Lamination Works Better

When laminating solar cells, clarity and adhesion are nonnegotiable. While generic lamination products may function, they often fall short under real manufacturing conditions. Fonitaniya™ BOPP Solar Tape (FON‑10023) delivers high transparency, secure bonding, reliable handling, and eco-conscious design, making it the smarter choice for modern solar panel producers.