In today’s electronics-driven world, electromagnetic interference (EMI) and radio-frequency interference (RFI) pose serious threats to device performance and signal integrity. One of the most effective and adaptable solutions is composite shielding tape—a material engineered to block unwanted electromagnetic signals while offering mechanical strength and flexibility.

What Is Composite Shielding Tape?

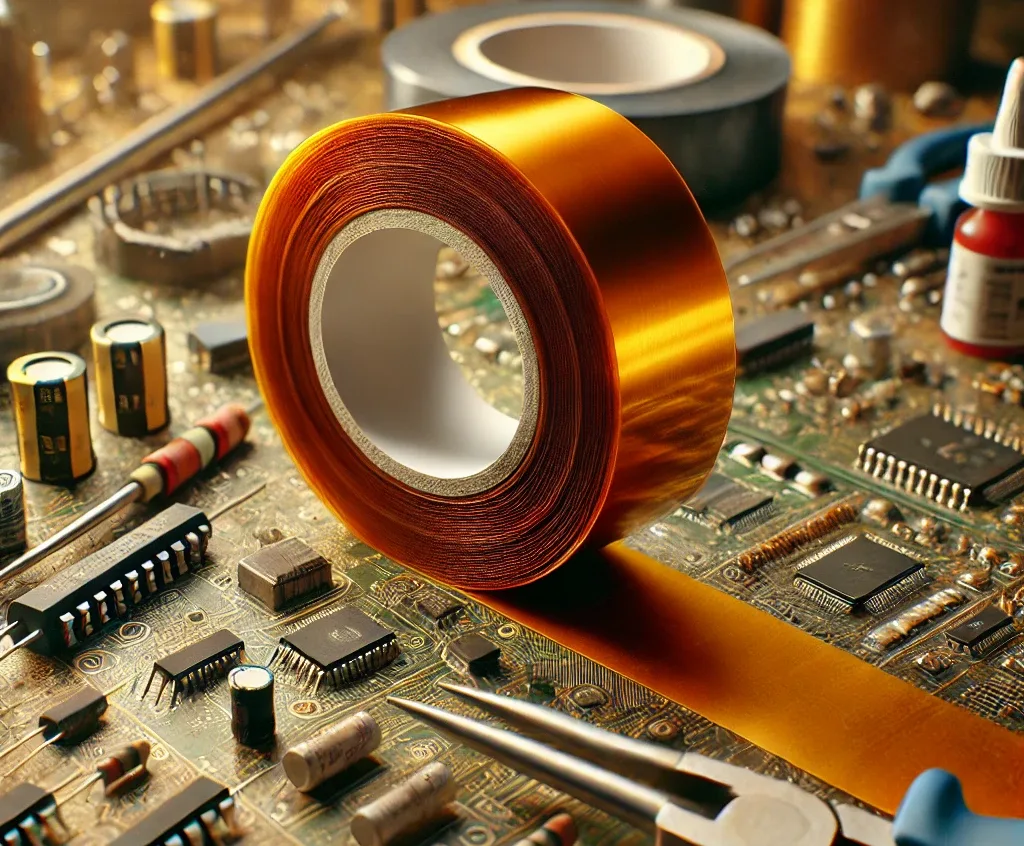

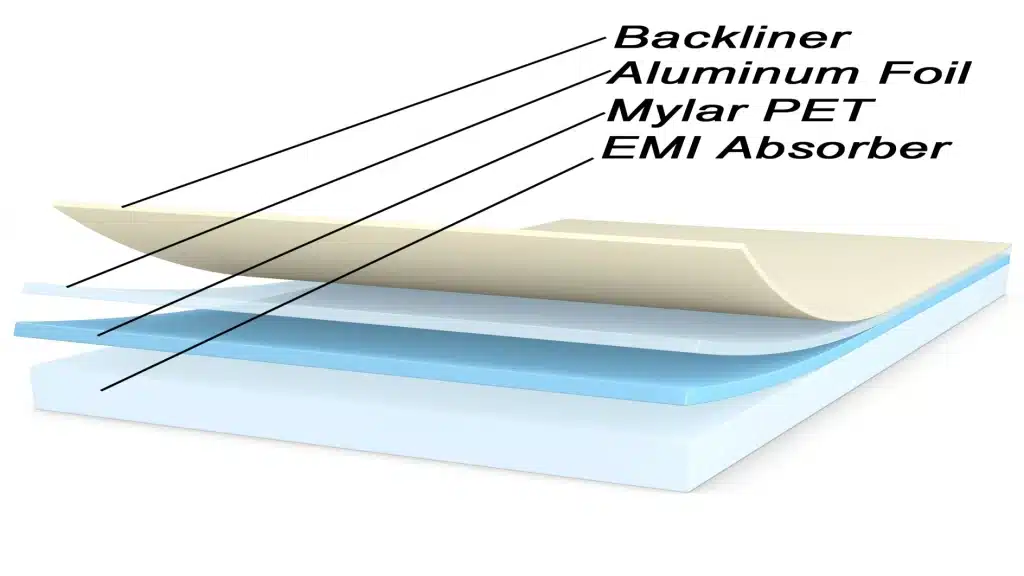

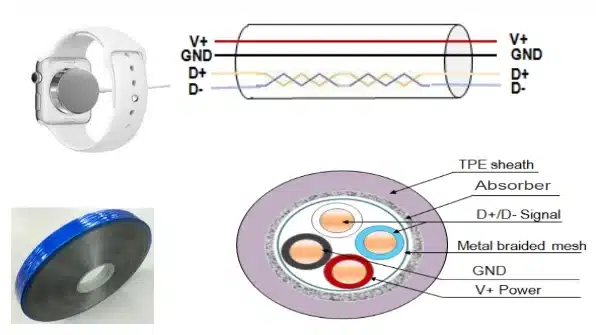

Composite shielding tape is a multi-layer conductive tape designed to prevent electromagnetic or radio-frequency emissions. It typically combines a metallic foil (like copper or aluminum) with a conductive adhesive and sometimes a protective or insulating layer. This combination makes it ideal for wrapping, grounding, or sealing electronic components in a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics.

Key Benefits of Composite Shielding Tape

- Effective EMI/RFI Shielding:

High shielding effectiveness across a wide frequency range (often 10 kHz to 10 GHz), making it suitable for both low- and high-frequency applications. - Flexible and Conformable:

The composite structure allows the tape to bend around complex shapes, connectors, or uneven surfaces without cracking or losing adhesion. - Thermal and Weather Resistance:

Many high-grade variants can withstand extreme temperatures and resist moisture, UV, and chemicals, ensuring long-term durability. - Easy Application:

Most tapes can be cut to shape and applied by hand, eliminating the need for special tools or curing processes.

Composite vs. Traditional Shielding Tapes

When comparing composite shielding tape to traditional single-material tapes like plain copper foil or aluminum tape, several advantages become clear:

| Feature | Composite Shielding Tape | Traditional Metal Tape |

|---|---|---|

| EMI Shielding | High, multi-directional | Moderate, directional |

| Flexibility | Excellent, adapts to curves | Limited, prone to tearing |

| Durability | Waterproof, heat-resistant | Susceptible to oxidation |

| Adhesion | Conductive and long-lasting | Often requires additional pressure |

| Layer Integration | Multi-functional layers | Single-purpose material |

While standard copper tapes may work for simple shielding, they often fall short in high-performance environments where moisture, vibration, or heat is a factor. Composite tapes are engineered to address these limitations.

Application Scenarios

Composite shielding tape is widely used in:

- Electronic Enclosures: Sealing gaps and joints in metal housings

- PCB Shielding: Covering traces and components for interference protection

- Wire & Cable Management: Enhancing grounding and shielding of cables

- Automotive Electronics: Protecting ECU and infotainment systems

- Aerospace Systems: Ensuring signal reliability in harsh environments

What to Look For When Choosing a Shielding Tape

To select the right composite shielding tape, consider the following:

- Shielding Effectiveness: Ensure the tape meets the dB attenuation requirements for your frequency range.

- Operating Temperature: Some applications require materials that tolerate temperatures up to 200°C or more.

- Adhesion Strength: Choose a product that bonds well with your surface material (plastic, metal, or coated substrates).

- Mechanical Strength: For environments with vibration or movement, opt for a tear-resistant and fatigue-resistant design.

- Environmental Resistance: For outdoor or high-humidity settings, select a tape with waterproof or UV-resistant properties.

Why a High-Performance Composite Shielding Tape Matters

Not all shielding tapes are created equal. Some cheaper alternatives use low-grade adhesive or non-reinforced foil, which can degrade over time, peel under stress, or fail to maintain consistent conductivity. On the other hand, premium composite tapes integrate reinforced fabrics, nanocoatings, and highly conductive adhesives—ensuring both shielding performance and physical reliability over time.

Choosing a well-engineered composite shielding tape is not just about blocking interference; it’s about future-proofing your design, minimizing field failures, and ensuring compliance with EMI regulations.

Conclusion

Composite shielding tape plays a vital role in EMI/RFI protection, offering a balance of performance, flexibility, and durability. While various options exist on the market, only a few stand out for their high-grade composite construction and long-term stability. For those seeking superior performance in critical applications, tapes like those offered by Fonitaniya deliver dependable results across a wide range of industries.