Have you ever struggled to find the perfect adhesive for your project, only to realize that ordinary tape just won’t cut it? Whether you’re mounting, bonding, or sealing, double sided foam tape is a game-changer in countless industries. In this article, we’ll explore the knowledge behind double sided foam tape. Let’s dive in!

What Is Double Sided Foam Tape?

The Basic Structure of Double Sided Foam Tape

Unlike regular tape, double sided foam tape features an internal foam core with adhesive coatings on both sides. This structure provides cushioning, flexibility, and excellent bonding capabilities, making it ideal for irregular surfaces.

How It Differs from Other Adhesive Tapes

Traditional double sided tapes work well for surface-level adhesion, but double sided foam tape offers enhanced grip, vibration resistance, and durability. It’s commonly used where mechanical fasteners are not feasible.

Why Foam Matters: Cushioning and Adhesion

Foam-based adhesives conform to different surfaces and distribute stress more evenly, reducing the risk of bond failure. This is why industries like automotive, construction, and signage rely on it for long-term applications.

Types of Double Sided Foam Tapes

Open-Cell vs. Closed-Cell Foam Tapes: Key Differences

Open-cell foam tape allows air and moisture to pass through, making it ideal for cushioning applications. In contrast, closed-cell foam tape provides a watertight seal, offering superior durability in harsh environments.

Common Adhesive Types: Acrylic, Rubber, and Silicone-Based

Acrylic adhesives provide high-temperature resistance and strong long-term bonding. Rubber adhesives offer affordability and immediate tack but degrade faster. Silicone adhesives withstand extreme conditions, making them ideal for aerospace and medical applications.

Thickness and Density: Choosing the Right Foam Tape

The thickness of double sided foam tape affects its performance. Thicker options absorb more impact, while thinner versions offer discreet yet strong adhesion. Density also plays a role—high-density foam tapes support heavier loads.

Double Sided Foam Tape Usage

Everyday Household Uses for Double Sided Foam Tape

From mounting picture frames to fixing carpets, double sided foam tape is a staple for DIY enthusiasts. It offers a clean alternative to nails, screws, and glue, preventing wall damage.

Industrial and Commercial Applications

Manufacturers rely on double sided foam tape for assembly lines, signage installation, and even automobile production. It reduces assembly time while ensuring strong, lasting bonds.

How It Compares to Other Fastening Solutions

Unlike screws or rivets, which require drilling, double sided foam tape provides a non-invasive, lightweight alternative. It also prevents corrosion and maintains aesthetic appeal without visible fasteners.

Considerations When Using Double Sided Foam Tapes

Surface Preparation: Ensuring Maximum Adhesion

For the best results, clean the surface with isopropyl alcohol and ensure it is dry before applying double sided foam tape. Any dust, grease, or moisture can weaken the bond.

Environmental Factors: Temperature and Humidity Effects

Extreme heat or cold can affect adhesive performance. Some foam tapes are designed for high-temperature resistance, while others may lose tack in freezing conditions.

Strength vs. Removability: Finding the Right Balance

Heavier-duty foam tapes provide permanent bonding, while low-tack versions allow for clean removal. Selecting the right type depends on whether you need a temporary or permanent hold.

How to Remove Double Sided Foam Tape

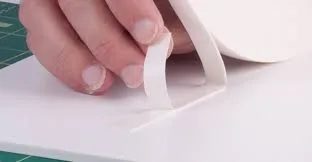

Safe and Effective Methods for Tape Removal

Start by gently peeling back the tape. If resistance occurs, use a hairdryer to soften the adhesive. For stubborn residue, consider using an adhesive remover.

Tools and Solvents That Help with Residue

Rubbing alcohol, citrus-based cleaners, or Goo Gone™ can effectively break down adhesive residue without damaging surfaces.

Preventing Surface Damage During Removal

Avoid using sharp tools like knives or metal scrapers, as they can scratch surfaces. Instead, opt for plastic scrapers or your fingertips for safe removal.

Applications and Benefits of Double Sided Foam Tapes

Automotive Uses: Trim, Badges, and More

Automotive manufacturers use double sided foam tape for securing emblems, weather stripping, and interior panels. It withstands temperature changes and vibrations effectively.

Construction and Home Improvement Applications

From installing mirrors to sealing gaps in HVAC systems, double sided foam tape enhances durability and insulation, making it invaluable for contractors.

The Advantages of Foam-Based Adhesion

Foam tape offers flexibility, noise reduction, and strong adhesion without damaging surfaces. Unlike liquid adhesives, it requires no curing time, making installations quicker and more efficient.

Conclusion

Double sided foam tape is an indispensable tool across multiple industries, providing strong yet flexible adhesion for a variety of applications. Whether for DIY projects or high-performance industrial use, it outperforms traditional fastening methods. At Fonitaniya, we have been pioneering adhesive solutions for over 15 years, ensuring high-quality products that meet the demands of modern industries. Explore our range of innovative foam tapes to find the perfect solution for your needs.

FAQs

How strong is double sided foam tape?

The strength of double sided foam tape depends on its adhesive type and thickness. High-performance tapes can support several kilograms of weight, making them ideal for heavy-duty applications.

Can double sided foam tape be used on all surfaces?

While double sided foam tape adheres well to most surfaces, certain materials like porous wood or rough concrete may require additional surface preparation for optimal bonding.

Is double sided foam tape waterproof?

Closed-cell foam tapes are highly water-resistant, making them suitable for outdoor applications. However, open-cell variants may absorb moisture and are better for indoor use.

How long does double sided foam tape last?

Depending on environmental conditions and adhesive quality, double sided foam tape can last anywhere from a few months to several years. Industrial-grade versions offer longer durability.

Can double sided foam tape withstand high temperatures?

Acrylic-based foam tapes can endure extreme heat up to 200°F (93°C), making them suitable for automotive and industrial use.

What is the best way to store double sided foam tape?

To extend shelf life, store double sided foam tape in a cool, dry place away from direct sunlight and extreme temperatures.

Can I reuse double sided foam tape?

Once applied and removed, most foam tapes lose their adhesion. However, some removable variants allow repositioning before they fully set.