Understanding High Bond Double-Sided Tape

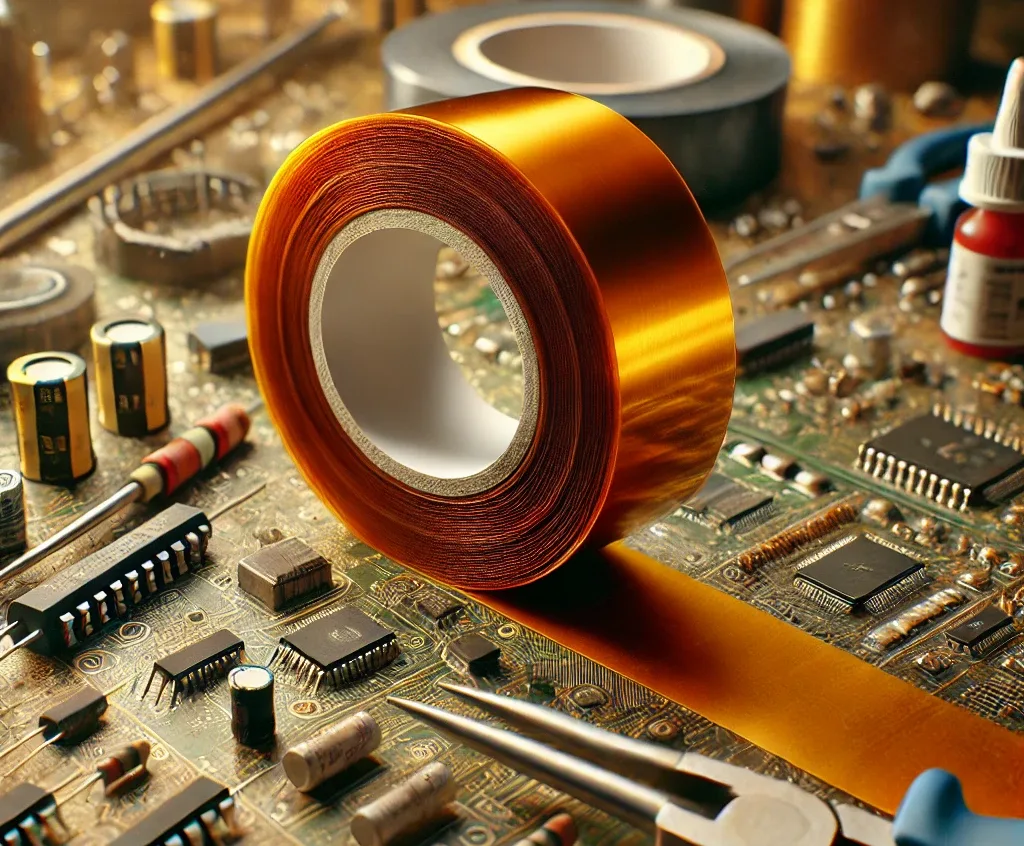

Double-sided tape with high bond adhesive is an industrial-grade bonding solution designed for strength, stability, and long-term performance. Unlike everyday tape, it features pressure-sensitive adhesive (PSA) on both sides of a carrier, creating a permanent, invisible bond between surfaces.

In high-performance applications—especially where bolts, screws, or liquid adhesives are unsuitable—high bond double-sided tapes are the go-to solution for clean, strong, and efficient mounting.

What Is High Bond Tape?

High bond tape refers to a class of double-sided adhesive tapes known for their extreme bonding strength, especially on materials like:

- Foam

- Plastics (including low surface energy plastics)

- Metals

These tapes often feature tackified acrylic adhesives, which provide long-lasting adhesion, heat resistance, and excellent shear performance.

Applications of High Bond Double-Sided Tape

Double-sided tape with high bond adhesive is suitable for various industrial scenarios. Some of the most common applications include:

- Foam and Felt Lamination

Used in HVAC systems, packaging, and sound insulation, foam needs strong bonding to stay effective. High bond tapes are excellent for adhering foam and felt to metal, plastic, or composite substrates.

- General Mounting

Perfect for signage, panel bonding, and other permanent installations that demand reliable adhesive performance.

- Industrial Assembly

In industries like automotive, electronics, and appliances, double-sided high bond tape provides vibration dampening and heat resistance, making it ideal for interior trim or insulation panel bonding.

Key Features of High Bond Double-Sided Tape

| Feature | Performance Description |

|---|---|

| Bonding Strength | Excellent on foam, metal, and plastics |

| Temperature Resistance | Stable adhesion under elevated temperatures |

| Adhesive Performance Over Time | Maintains high static shear and bonding strength |

| Customization (Converting) | Easy to die-cut or convert into custom shapes for automation or precision tasks |

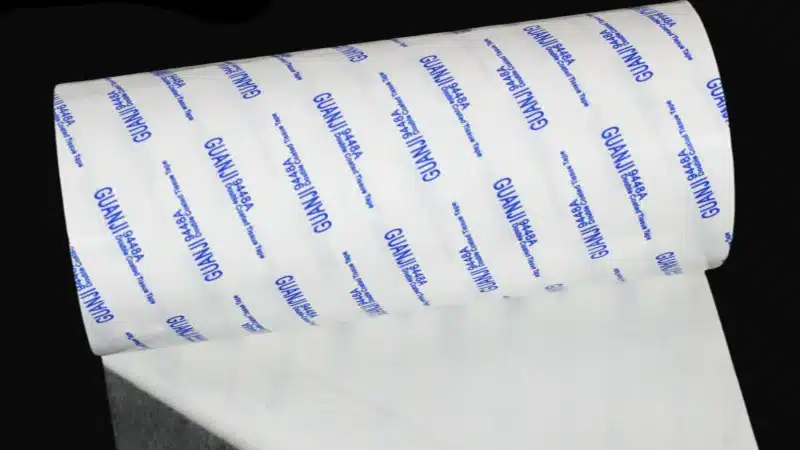

| Carrier Material | Flexible non-woven backing allows better surface conformity |

What Is the Strongest Double-Sided Adhesive Tape?

The strongest double-sided tapes are typically high bond acrylic or modified acrylic adhesive tapes with a non-woven, foam, or solid film carrier. These tapes are designed to:

- Replace mechanical fasteners

- Provide shock absorption

- Resist high temperatures

- Adhere to uneven or curved surfaces

Comparing Two High-Performance Double-Sided Tapes

| Comparison Criteria | High Bond Non-Woven Tape (FON 10141) | Standard Acrylic Foam Tape |

|---|---|---|

| Bonding Strength | Strong on foam, plastic, metal | Strong on metal, glass |

| Flexibility | Excellent – conforms well due to non-woven backing | Moderate – foam-based, slightly rigid |

| Temperature Resistance | High – suitable for heat-intensive applications | High – with thermal foam core |

| Converting Ability | Easy to die-cut and shape | More difficult to customize |

| Adhesive Type | Tackified acrylic adhesive | Solid acrylic core adhesive |

| Typical Use Cases | Lamination, general mounting, custom components | Structural bonding, glass paneling |

Final Thoughts: Finding the Strongest Double-Sided Tape for Your Needs

When it comes to bonding strength, temperature resistance, and long-term durability, not all double-sided tapes perform equally. While foam-based acrylic tapes offer robust structural support, high bond non-woven tapes provide superior flexibility, converting ease, and multi-surface compatibility—making them ideal for general-purpose and specialty lamination.

If your application demands strong bonding on foam, plastic, or metal, with reliable temperature resistance and adaptability, trust FON 10141 by Fonitaniya—a dependable choice in high-performance adhesive solutions.