Have you ever paused to consider how the right adhesive can make or break the efficiency of HVAC systems? In the world of heating, ventilation, and air conditioning, using the appropriate tape is more critical than many might realize. This article explores the application of foil tape in HVAC installations while highlighting when to opt for it over traditional foil tape, methodologies for use, and how this versatile tape enhances overall system performance.

When to Use Foil Tape Over Film Tape in HVAC?

Choosing the right tape for HVAC applications can significantly impact both installation quality and long-term system performance. While foil tape remains a popular choice due to its durability and suitability for many HVAC tasks, film tape offers unique benefits in specific scenarios.

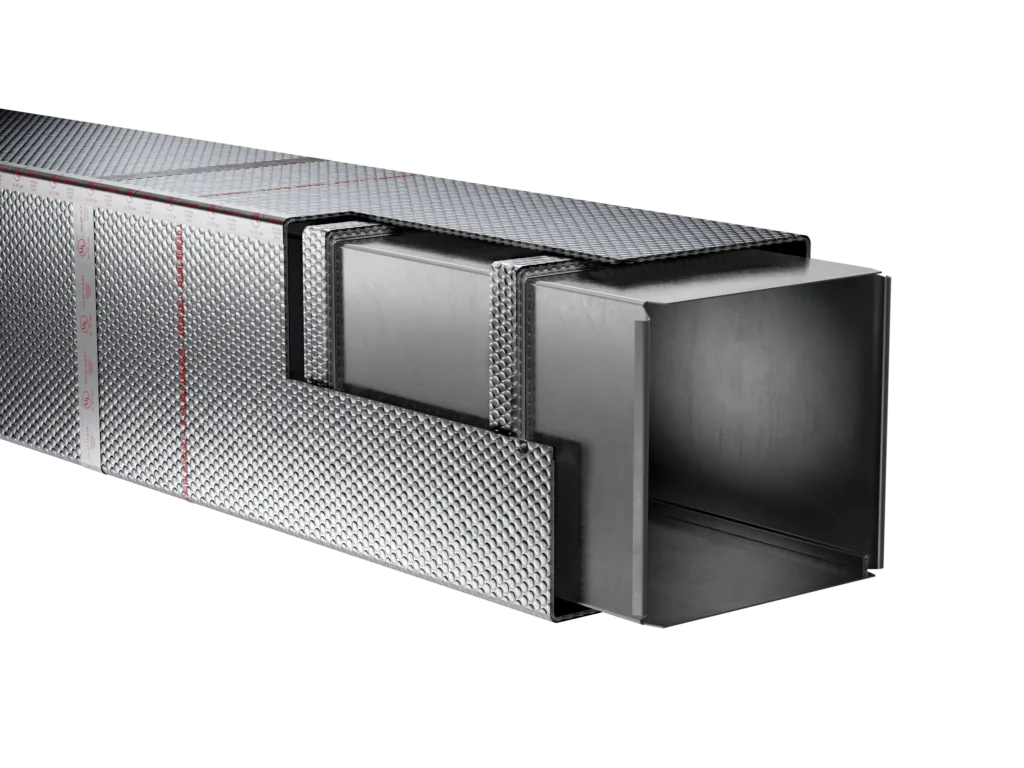

Film tape often excels in instances where precision and conformability are paramount. For example, reflective insulation presents a challenge when using foil tape, as it can struggle to adhere to irregular surfaces and ridges. As installation professionals know, reflective insulation is designed to reflect heat and maintain energy efficiency, but its textured surfaces can hinder the effectiveness of foil tapes. Here’s where film tape shines.

Thanks to its ability to conform to uneven surfaces, film tape can get into the challenging contours and ridges of reflective insulation, ensuring maximum surface contact. The film tape’s adhesive works effectively in a wide array of conditions, even in spaces subject to thermal cycling.

Moreover, film tapes maintain many beneficial features found in foil tapes, such as UL Listing and the possibility for printing. This versatility means that HVAC technicians can use film tape for diverse applications, ensuring a reliable seal every time. The decision to utilize film tape often hinges upon the environment and specific application requirements, making it a preferred choice under various circumstances within HVAC systems.

Related article: What tape to use in HVAC system?

How to Use Foil Tape on Reflective Insulation Systems

When it comes to installing reflective insulation on HVAC ducts, the proper application of tape is vital for maximizing insulation performance. Foil tape serves not only to attach insulation strips but also to seal the outer layer, creating an effective barrier against air leaks.

The installation process begins with taping 2-3 inch wide strips of reflective insulation around the duct. Technicians typically apply these strips at intervals, leaving critical gaps to achieve a high R-value. The R-value is a measure of insulation effectiveness; higher R-values indicate better insulating properties. In many commercial HVAC systems, maintaining a high R-value can significantly reduce energy costs – often by as much as 10-20%.

After placing the spacer strips, the technician will cut a customized sheet of reflective insulation material, wrapping it securely around the entire outside of the air duct. At this stage, choosing a high-quality, UL-listed foil tape is key. It secures the seams and edges, providing an airtight seal crucial for optimizing the R-value and preventing energy loss. The tape’s adhesive forms a permanent bond that withstands moisture, humidity, and temperature fluctuations.

Details matter in this process. The seal created by foil tape isn’t merely a cosmetic enhancement; it acts as the primary barrier against air leaks. Failing to achieve a proper seal can compromise the entire insulation system, leading to substantial inefficiencies in HVAC operations. Indeed, poorly sealed ducts can increase energy costs by over 30%, according to the Department of Energy. Therefore, it is paramount to prioritize high-quality materials to ensure the long-term effectiveness of HVAC systems.

How Is Foil Tape Used in Abatement Jobs?

While foil tape is predominantly associated with HVAC applications, it plays a critical role in abatement and restoration tasks as well. Specifically, its capabilities extend to sealing metal and sheet metal repairs, which are often essential in preventing contaminants from entering or escaping during the abatement process.

For instance, during abatement jobs where a duct may need sealing after inspecting it for water damage due to fire or flooding, the UL listing of foil tape becomes vital. Code compliance is non-negotiable; selection of the right tape ensures that it meets safety standards and performs reliably when needed most. Using an unlisted or inferior tape could lead to inspection failures, resulting in costly delays.

Beyond compliance, consider the performance characteristics of foil tape in a range of temperatures, including extreme heat and cold, as well as its capability to create permanent airtight and waterproof seals. During abatement, metal surfaces often require repairs, and using foil tape effectively seals these areas from environmental factors while promoting safety compliance.

For example, when working on a commercial space that has undergone renovation after water damage, professionals might use foil tape to seal any patched-up ductwork thoroughly. This ensures that the air quality is maintained, and the HVAC system operates efficiently post-restoration.

Conclusion

In conclusion, understanding the applications of foil tape in HVAC installations is vital to ensuring air quality, temperature regulation, and overall energy efficiency in commercial and residential spaces. By knowing when to utilize film tape over foil tape, as well as the proper methods for applying these materials, HVAC professionals can significantly enhance the quality of their work. Fonitaniya tape has been a leading adhesive solution provider for over 15 years, dedicated to delivering innovative foil tape options for a wide range of applications. As you explore the potentials of foil tape, depend on our expertise to elevate your HVAC projects to new heights of efficiency.

FAQs

What is foil tape used for in HVAC applications?

Foil tape is essential for sealing ducts and reflective insulation to achieve energy efficiency.

Can I use foil tape on all types of insulation?

Foil tape works best on reflective insulation and may not adhere well to other materials.

How long does foil tape last in HVAC systems?

High-quality foil tape can last for many years when installed properly, ensuring durability.

Does foil tape provide a good air seal?

Yes, foil tape creates an effective, airtight barrier, crucial for maintaining HVAC efficiency.

Is foil tape resistant to humidity?

Foil tape is designed to resist moisture, making it suitable for various environmental conditions.