Did you know that electromagnetic interference (EMI) can disrupt everything from your smartphone to lifesaving medical devices? It’s an invisible disruptor that most of us take for granted until it starts to interfere with our daily lives. In this article, we’re diving into the phenomenon of EMI, exploring how it’s measured, and revealing the most effective ways to reduce it. Along the way, you’ll learn how shielding tape plays a vital role in safeguarding modern technology, ensuring everything runs smoothly in an increasingly connected world.

Is Electromagnetic Interference Good or Bad?

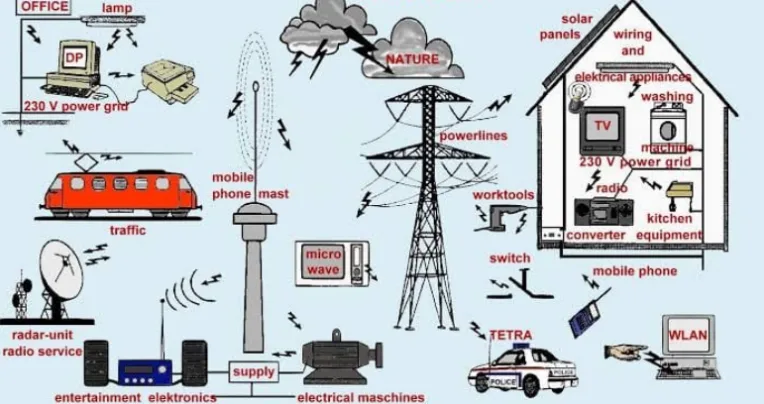

Electromagnetic interference, or EMI, is the unintentional disturbance caused by electromagnetic waves interfering with the performance of electronic devices. At its core, EMI is neither inherently good nor bad—it’s simply a phenomenon of physics. However, its impact can swing wildly depending on the context.

In our daily lives, EMI can be an annoying inconvenience. You’ve likely experienced this if your Bluetooth headphones cut out in a crowded subway or your Wi-Fi connection slows down when too many devices are connected. These are small but familiar examples of how EMI disrupts the seamless operation of technology.

In industries, however, EMI can have far-reaching consequences. Consider the aviation industry, where the integrity of communication and navigation systems is critical. Without proper shielding, external interference could compromise these systems, creating a safety risk. Similarly, in healthcare, EMI can affect sensitive medical devices like pacemakers and MRI machines, leading to potentially life-threatening errors. The financial impact of EMI isn’t trivial either. According to a report by MarketsandMarkets, industries globally spend billions annually on EMI shielding solutions to maintain system integrity and reliability.

While natural EMI from sources like solar flares cannot be avoided, man-made EMI, often caused by industrial machinery or poorly shielded electronics, can and should be mitigated to protect technology and lives.

How to Measure EMI/RFI

Measuring electromagnetic interference is as much an art as it is a science. Engineers rely on highly specialized tools to identify and quantify interference across different frequency ranges. A common device used is a spectrum analyzer, which detects and visualizes electromagnetic waves within specific frequencies.

For instance, a technician might use a spectrum analyzer to evaluate a malfunctioning server room. If the analyzer shows interference peaking at certain frequencies, the source of the disturbance—perhaps a poorly shielded cable or nearby industrial equipment—can be pinpointed.

Field probes and antennas are also employed to measure EMI in larger environments, such as factories or outdoor installations. Regulatory agencies, like the Federal Communications Commission (FCC) in the United States, often set limits on EMI emissions for various devices. Compliance testing, which measures whether a product adheres to these limits, is a critical part of designing and manufacturing electronics.

The process of measurement often involves isolating each component to determine where interference originates. In environments like data centers, engineers may use near-field probes to identify specific devices or cables that are contributing to EMI. Accurate measurement is the first step to effective mitigation.

Three Methods to Reduce EMI

There are three primary approaches to reducing electromagnetic interference: shielding, filtering, and grounding.

Shielding

Shielding involves creating a physical barrier between the source of interference and sensitive equipment. Materials like copper, aluminum, and conductive foams are commonly used to absorb or reflect electromagnetic waves. For instance, shielding enclosures are often used in medical environments to protect imaging equipment like MRI scanners from external interference.

Filtering

Filtering removes unwanted electromagnetic noise from power or signal lines. Devices such as capacitors and inductors are used to block high-frequency interference while allowing the intended signal to pass through. A typical example is the use of EMI filters in power supplies, which ensures that electrical noise doesn’t disrupt the operation of sensitive components.

Grounding

Grounding provides a pathway for excess electromagnetic energy to dissipate safely into the Earth. This is especially important in industrial settings, where large equipment generates significant EMI. Proper grounding not only minimizes interference but also enhances the safety of electrical systems by preventing dangerous voltage buildups.

How to Reduce Electromagnetic Interference with Shielding Tape

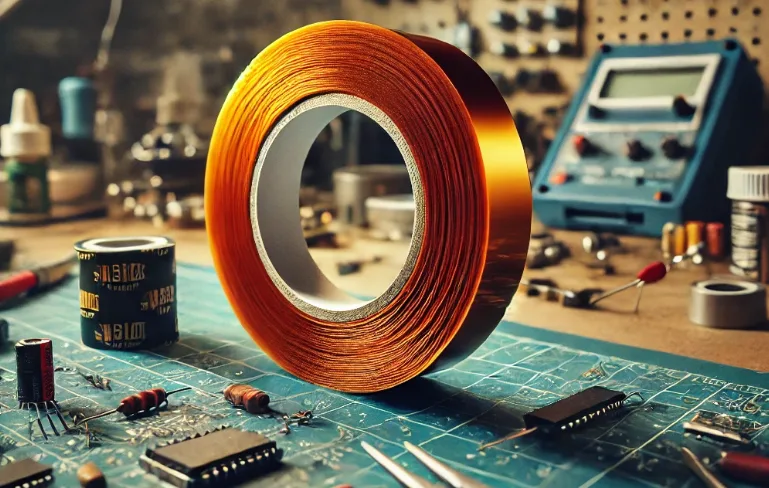

EMI shielding tape offers a versatile and effective solution for mitigating electromagnetic interference across various applications. Available in materials like copper, aluminum, and conductive fabrics, these tapes are designed to block electromagnetic waves and create interference-free environments for sensitive electronics.

Various Shielding Tapes

Copper EMI shielding tape is known for its excellent conductivity and durability, making it a popular choice in high-performance applications like telecommunications. Aluminum shielding tape, on the other hand, is lightweight and cost-effective, often used in consumer electronics. Conductive fabric tapes provide flexibility, allowing them to conform to irregular shapes in compact devices.

Applications in Different Scenarios

In a data center, copper EMI shielding tape can be applied to cables and server racks to reduce cross-talk and maintain data integrity. Meanwhile, in automotive engineering, aluminum shielding tape is used to protect electrical systems from interference caused by the ignition process. For medical devices, conductive fabric tape ensures shielding without adding significant weight, preserving the portability of equipment like wearable monitors.

Even in home environments, shielding tape proves its worth. DIY enthusiasts often use it to shield audio equipment, ensuring pristine sound quality by blocking external interference. Regardless of the setting, shielding tape serves as an essential tool in the fight against EMI.

Conclusion

Electromagnetic interference is an inevitable byproduct of a technologically advanced world, but it doesn’t have to be a disruptive force. By understanding its sources and impacts, we can take proactive measures to mitigate it through shielding, filtering, and grounding. Among these, EMI shielding tape stands out as a cost-effective, versatile solution for reducing interference across a wide range of applications.

For over 15 years, Fonitaniya™ has been at the forefront of adhesive innovation, providing reliable EMI shielding tapes and other specialty solutions. Whether you’re protecting high-performance servers or crafting the next generation of consumer electronics, our expertise ensures that your technology performs flawlessly in even the most challenging environments.

FAQs About Electromagnetic Interference

How does EMI affect communication systems?

Electromagnetic interference can distort or block signals, leading to poor performance in wireless networks, radios, and telecommunication systems.

What tools are used to measure EMI?

Spectrum analyzers and field probes are commonly used to detect and quantify electromagnetic interference in specific environments.

Can shielding tape prevent all types of interference?

Shielding tape significantly reduces interference by blocking or absorbing electromagnetic waves, but its effectiveness depends on material choice and proper application.

Is EMI only a problem in industrial environments?

EMI affects consumer electronics, healthcare devices, automotive systems, and many other fields, not just industrial equipment.

What industries benefit most from EMI shielding?

Industries such as telecommunications, aerospace, healthcare, and automotive rely heavily on EMI shielding to ensure system reliability and safety.