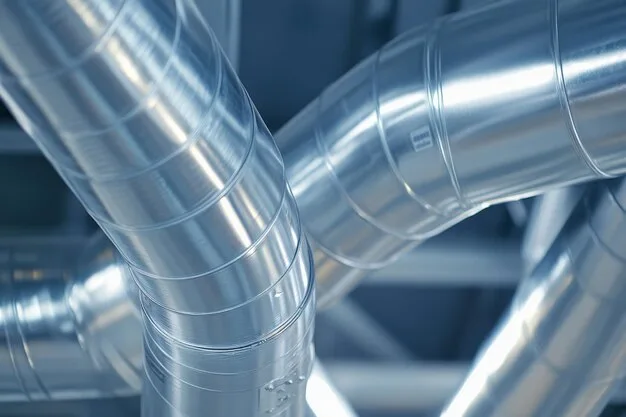

Did you know that up to 30% of air escapes through poorly sealed HVAC systems, driving up energy costs and reducing efficiency? This invisible drain on resources often goes unnoticed but can easily be prevented. In this article, we’ll uncover the critical role HVAC tape plays in optimizing HVAC systems. From sealing reflective insulation to ensuring indoor air quality and withstanding extreme weather, we’ll explore everything you need to know about making your HVAC system perform at its best.

Why Does Tape Often Fail on Reflective Insulation?

Tape failure is a common challenge when sealing reflective insulation in HVAC systems. Reflective insulation, praised for its ability to reduce energy costs, must achieve full system closure to work effectively—a task heavily reliant on the tape used. However, reflective insulation is often installed in unconditioned spaces, such as attics and crawlspaces, where extreme temperature swings occur.

The Role of Thermal Cycling

Thermal cycling—the repeated heating and cooling as seasons change—takes a toll on many tapes. Poor-quality tapes may shrink in summer’s heat or become brittle in winter’s cold. According to Reflective Insulation Manufacturers Association International (RIMA-I), reflective insulation projects lose up to 20% efficiency due to improperly sealed ductwork.

How to Select Durable Tape for Reflective Insulation

To avoid failure, always choose HVAC tape engineered for thermal durability. Look for tapes designed to withstand cycles from scorching summers to freezing winters while maintaining a permanent seal. This ensures reflective insulation operates at peak efficiency, delivering on its promise of energy savings.

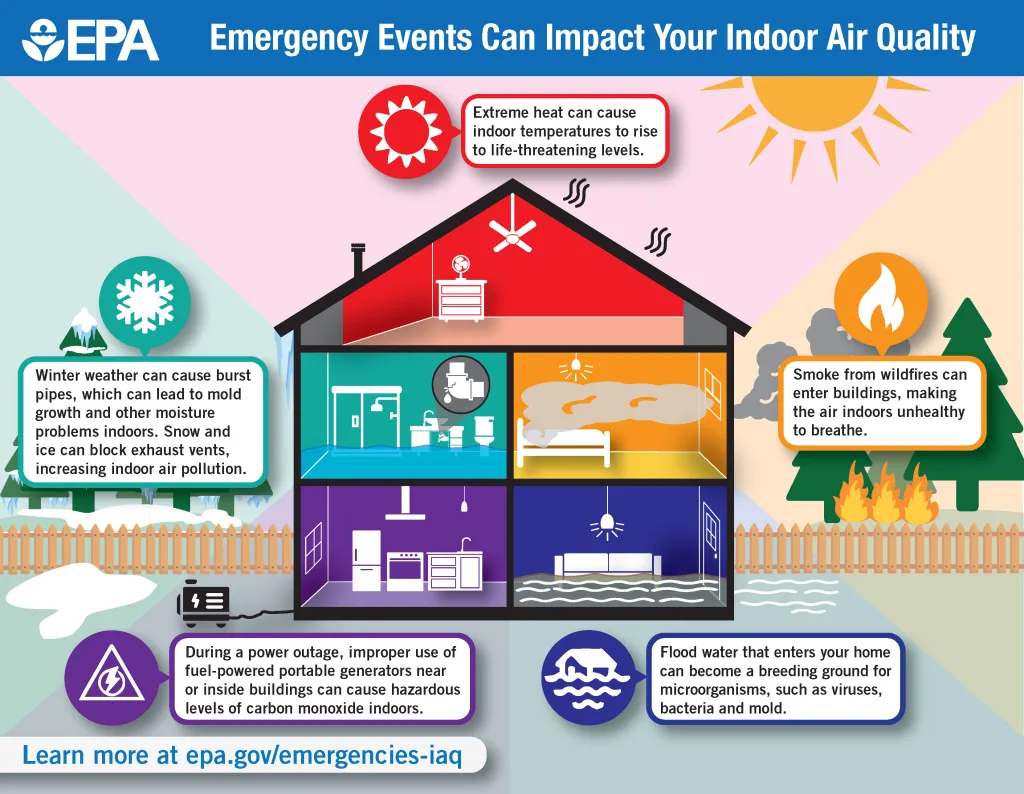

How Does HVAC Tape Choice Impact Indoor Air Quality?

Indoor air quality (IAQ) is vital for our health, with the EPA ranking indoor air pollution among the top five environmental risks. Poor IAQ doesn’t just trigger allergies; it causes headaches, asthma, fatigue, and even serious respiratory conditions. The modern HVAC system’s job isn’t just to heat or cool but also to filter contaminants like dust, pollen, and bacteria. A tightly sealed system is essential to achieve this.

The Importance of a Sealed System

HVAC tape plays a pivotal role in creating this sealed environment. It connects and seals ducts, air handlers, and other components. Tape failure—when it flags, peels, or doesn’t adhere properly—causes air leaks, allowing contaminants to escape back into your living or working space.

Selecting the Right Tape for IAQ

Choosing the right HVAC tape ensures effective sealing in all conditions. For example, high-humidity environments require moisture-resistant adhesives, while reflective insulation demands specialized tapes for adhesion. Proper application is just as critical. Use tools like squeegees to eliminate air bubbles, ensuring a lasting bond. A small oversight in tape quality or application can compromise IAQ, so make HVAC tape selection a top priority.

Related article: Pro tips for applying HVAC tape.

HVAC Remodel vs. New Construction: Things to Consider

HVAC projects differ greatly depending on whether you’re working on a new construction or remodeling an existing system. Both scenarios present unique challenges where HVAC tape can make or break the outcome.

New Construction Requirements

For new construction, strict standards for safety and energy efficiency must be met. Building codes often require contractors to use UL Listed tapes, which have passed rigorous testing for durability, temperature resistance, and performance. Using subpar tape can result in failed inspections and inefficiencies from the start.

Challenges in Remodeling Projects

Remodeling projects, on the other hand, are less predictable. Contractors often face unknown conditions, such as outdated systems or previous quick fixes. For instance, many older systems were sealed with general-purpose duct tape, which is not designed for HVAC work. When addressing these issues, contractors must replace failing seals with high-performance HVAC tape to restore system integrity and meet current codes.

Best Practices for Both Scenarios

Whether installing a new system or repairing an old one, understanding the condition and requirements of the HVAC setup is key. A smart choice in HVAC tape ensures long-term performance and compliance, preventing costly rework.

HVAC Tape – Cold Temperature Application

Applying HVAC tape in cold conditions presents unique challenges. Many adhesives struggle to perform in low temperatures, becoming brittle or failing to adhere altogether. This is especially critical for HVAC systems located in unconditioned spaces, like garages or basements, where temperatures can plummet below freezing.

Challenges of Low-Temperature Adhesion

Cold temperature tapes are specially engineered to maintain adhesion even in subzero conditions. According to a study by the North American Insulation Manufacturers Association (NAIMA), tapes designed for cold applications maintain their bond at temperatures as low as -20°F. These tapes feature advanced adhesive technology that stays pliable and sticks effectively, even in the harshest environments.

Tips for Successful Application

To ensure success, always clean and dry the surface before applying the tape. Moisture or frost can interfere with adhesion, leading to early failure. Investing in cold-temperature HVAC tape not only ensures a secure seal but also prevents future headaches as temperatures fluctuate.

How Does Weather Impact HVAC Tape Performance?

Weather plays a significant role in determining HVAC tape’s performance. Extreme temperatures and humidity levels during and after installation can compromise adhesion if the wrong tape is used.

Application Temperature vs. Service Temperature

Application temperature is the first factor to consider. Tapes must bond securely during installation, but high temperatures can make adhesives too fluid, while cold temperatures can render them glass-like and ineffective. Service temperature is equally important. HVAC systems undergo thermal cycling—a stressor that tests the tape’s durability over time.

Impact of Humidity

Humidity adds another layer of complexity. High humidity can create a moisture film on surfaces, weakening the bond. This is particularly common in tropical or coastal regions. Experts at the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) recommend using moisture-resistant HVAC tape for such environments to ensure long-term performance.

How to Weatherproof HVAC Systems

Selecting the right tape for the job’s specific weather conditions is non-negotiable. Doing so ensures your HVAC system remains efficient and airtight, regardless of external factors.

Conclusion

A well-optimized HVAC system relies on the quality of its components, and HVAC tape is no exception. From sealing reflective insulation to withstanding harsh weather, the right tape can enhance system efficiency, improve air quality, and lower energy costs. At Fonitaniy Adhesive Tape, we’ve spent over 15 years perfecting adhesive solutions, including our innovative HVAC tape line. Our mission is to provide contractors and homeowners with reliable products that stand the test of time.

FAQs

What makes HVAC tape different from regular duct tape?

HVAC tape is designed to withstand extreme temperatures, humidity, and thermal cycling, unlike general-purpose duct tape.

How long does HVAC tape last?

High-quality HVAC tape can last for years, but its longevity depends on application quality and environmental conditions.

Can HVAC tape be used in high-humidity areas?

Yes, certain HVAC tapes are specifically engineered for high-humidity conditions to ensure a secure and long-lasting bond.

Is reflective insulation tape the same as HVAC tape?

Reflective insulation tape is a type of HVAC tape designed for reflective surfaces and high-temperature durability.

What is UL Listed tape, and why is it important?

UL Listed tape meets stringent safety and efficiency standards, ensuring it performs under the demanding conditions of HVAC systems.

How do I ensure HVAC tape adheres properly?

Clean and dry the surface, use the right tape for the job, and apply it firmly with tools like a squeegee for an airtight seal.