Did you know that HVAC systems account for nearly 50% of energy consumption in a typical home, according to the U.S. Department of Energy? In the world of heating, ventilation, and air conditioning (HVAC), having the right tools and materials for the job can drastically impact efficiency and performance. This article delves into the intricacies of HVAC tape, exploring its characteristics, compliance, and application techniques. Whether you’re an industry veteran or new to HVAC solutions, we’re here to provide you with a comprehensive guide that balances technical insights with approachable expertise.

- What Characteristics of HVAC Tape?

- How to Determine if an HVAC Tape is UL Compliant

- What’s the Difference Between HVAC Tape Backings?

- For HVAC Tape, What are Application and Service Temperature?

- What is Full System Closure in an HVAC System?

- How to Achieve HVAC Full System Closure with HVAC Tape

- Conclusion

- FAQs

What Characteristics of HVAC Tape?

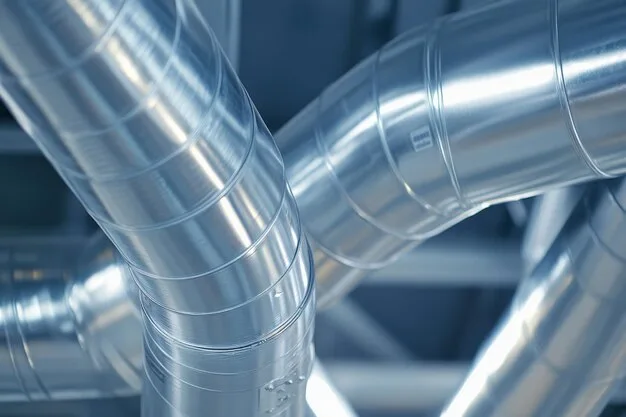

HVAC applications present unique challenges that require specially designed solutions. HVAC tape is engineered to withstand extreme temperatures, moisture, and varying levels of pressure within ventilation systems. These environments demand a tape with superior adhesive strength, flexibility, and resistance to aging.

A critical feature of HVAC tape is its temperature range adaptability. It must remain effective under both high heat and chilling cold without losing adhesion. Moreover, the tape should resist moisture infiltration, as even a small breach could lead to rapid efficiency loss. The durability of the tape material also ensures it sustains the physical stress of duct vibrations and movements.

How to Determine if an HVAC Tape is UL Compliant

Ensuring your HVAC tape is UL compliant is a vital consideration for safety and regulation adherence. UL (Underwriters Laboratories) listings offer verification that a tape meets rigorous safety standards.

What is UL Listing?

A UL listing signifies that a product has been tested and meets specific safety specifications. With regard to HVAC tape, UL ensures that the material itself doesn’t contribute to fire hazards or other safety issues in heating and cooling systems.

Types of UL Listings

HVAC tape may receive different types of UL listings, such as UL 181A or UL 181B, which pertain to duct closure systems. Each classification provides guidelines on application techniques, testing standards, and limitations.

How to Find Out if HVAC Tape is UL Compliant

Determine the compliance of HVAC tape by checking the packaging or the manufacturer’s product description. You can often find the UL listing number printed directly on the tape roll or box. Additionally, details are typically listed in product datasheets available from suppliers like GlobalSpec or directly from the manufacturer.

What’s the Difference Between HVAC Tape Backings?

Choosing the right backing for HVAC tape affects its performance and suitability for different applications.

Film Backings

Film backings offer a lightweight and flexible solution for HVAC tape. They resist tearing and provide excellent conformability to irregular surfaces, making them suitable for irregular duct surfaces.

Cloth Backings

Cloth backings introduce high tensile strength, ensuring durability where mechanical stress is present. This type of backing is ideal for high-pressure HVAC systems where additional reinforcement is necessary.

Foil Backings

Foil backings provide superior temperature resistance and reflectivity, effectively sealing joints in exhaust systems exposed to high heat. According to HVAC professionals, foil-backed tapes excel in environments where maintaining temperature is critical, such as in heating vents or reflective installations.

For HVAC Tape, What are Application and Service Temperature?

The application temperature refers to the range within which the tape can be installed and still maintain optimal adhesive characteristics. Service temperature, on the other hand, pertains to the extremes within which the tape can function effectively without degradation.

For HVAC tapes, typical application temperatures range from 32°F to 140°F (0°C to 60°C), while service temperatures might span -20°F to 180°F (-29°C to 82°C). Selecting tape with the correct temperature specifications ensures that it performs reliably under expected environmental conditions.

What is Full System Closure in an HVAC System?

Achieving full system closure ensures that there are no leaks or inefficiencies that could compromise HVAC effectiveness.

Application Technique

Proper technique ensures the tape’s adhesive can bond effectively. This means applying even pressure across the tape’s surface and avoiding wrinkles that could create air pockets.

Environmental Conditions

Environmental factors can drastically affect tape performance. Ensure that conditions are within product specifications during application, especially with regard to temperature and humidity.

Application Surface

Prepping the surface by cleaning and smoothing it ensures maximum adhesion. Any debris or irregularities can prevent a complete seal, risking air leaks or inefficiency.

Code Compliance

Adhering to local building codes and standards, such as those set by UL or ASTM, not only ensures effectiveness but also legal compliance. Non-compliance can lead to system inefficiencies and potential liability issues.

How to Achieve HVAC Full System Closure with HVAC Tape

Metal to Metal Transition

For metal-to-metal transitions, using butyl foil tape is recommended. Butyl foil tape provides excellent adhesion to metal surfaces and is less prone to temperature-related issues, a factor highlighted during UL-related inspections. Its excellent sealing ability ensures no energy loss through metal seams.

Connecting Insulate Pipe

Aluminum foil glass cloth tape is highly recommended for connecting insulated pipes. It offers heat resistance and durability, ensuring the integrity of insulation materials and maintaining the system’s efficiency. Its strength allows it to withstand physical pressure within duct systems.

Duct Tape to Metal Transitions

Regular duct tape can be used effectively when transitioning between duct tape and metal surfaces. Its versatility, easy tearability, and strong adhesive make it suitable for temporary fixes and less critical applications, provided the conditions fit within its adhesive tolerance.

Conclusion

In conclusion, understanding HVAC tape’s characteristics and proper application strategies is crucial for effective system performance. With the right knowledge, HVAC tape can dramatically enhance the efficiency and reliability of your HVAC system. At Fonitaniya™, we’ve spent over 15 years evolving HVAC tape solutions to meet the demanding needs of modern systems, providing you with reliability and peace of mind.

FAQs

What is HVAC tape used for?

HVAC tape is used for sealing ducts, ensuring full system closure, and preventing energy loss.

Is HVAC tape heat resistant?

Yes, most HVAC tapes are designed to withstand a broad range of temperatures.

How to tell if HVAC tape is UL compliant?

Look for UL certification details on the packaging or product description.

Can HVAC tape be used outdoors?

Yes, but ensure it is rated for exposure to elements and temperature variations.