Adhesive tapes are an integral part of our daily lives, serving countless purposes across various domains. From simple household tasks to complex industrial applications, adhesive tapes provide a convenient and effective solution for bonding, sealing, and repairing. Despite their ubiquitous presence, many people are unaware of the diverse types of adhesive tapes available and their specific uses. Understanding the various kinds of adhesive tapes and their unique properties can help consumers make informed choices, ensuring they select the right tape for their needs.

What Is the Purpose of Adhesive Tapes?

Adhesive Tapes in Daily Life

In the home, adhesive tapes are used for sealing packages, repairing broken items, and securing loose objects. For instance, packing tape is essential for securing boxes during moves or when shipping items. Similarly, clear adhesive tapes are commonly used for wrapping gifts, mending torn paper, and a myriad of other household chores. The versatility and ease of use make adhesive tapes indispensable in domestic settings.

Beyond basic household use, adhesive tapes are also essential in DIY projects and home improvement tasks. Masking tape, for example, is widely used during painting to protect surfaces and ensure clean, straight lines. Double-sided tapes are perfect for mounting items on walls without the need for nails or screws, preserving the integrity of surfaces. These tapes offer strong adhesion while being easy to remove without leaving residue, making them ideal for temporary applications.

Industrial and Professional Uses of Adhesive Tapes

Industries such as automotive, construction, and electronics rely heavily on various types of adhesive tapes to enhance efficiency and ensure safety. For example, in the automotive industry, adhesive tapes are used for bonding components, securing wires, and providing insulation. Automotive tapes are designed to withstand extreme temperatures and harsh conditions, ensuring long-lasting performance.

In the construction industry, adhesive tapes are used for sealing joints, bonding insulation materials, and providing waterproofing solutions. Duct tapes, known for their strong adhesion and versatility, are often employed in repair and maintenance tasks. Their ability to adhere to different surfaces and resist moisture makes them ideal for both indoor and outdoor applications. Additionally, specialty tapes such as anti-slip tapes are used to enhance safety in high-traffic areas, preventing accidents and ensuring compliance with safety regulations.

The electronics industry also benefits significantly from adhesive tapes. Electrical tapes, designed to insulate and protect electrical connections, are essential for ensuring the safety and reliability of electronic devices. These tapes provide excellent resistance to heat and electrical currents, making them indispensable in various electronic applications.

What Are the Types of Adhesive Tapes?

Adhesive tapes come in a myriad of types, each designed for specific applications and environments. Understanding the various types of adhesive tapes and their unique properties can help users select the most suitable tape for their needs.

Specialty & Anti-Slip Tape

Specialty tapes are designed for specific applications that require unique properties not found in standard adhesive tapes. These tapes often possess specialized features such as extreme temperature resistance, enhanced durability, or specific adhesive qualities tailored for niche applications. For instance, high-temperature tapes are used in environments where standard adhesives would fail due to heat degradation. These tapes are often employed in industries such as aerospace, automotive, and electronics, where maintaining adhesion under extreme conditions is critical.

Specialty tapes also include products like double-sided tapes, which are used for bonding materials without visible tape lines. These tapes are particularly useful in applications requiring clean aesthetics, such as in the display and signage industry. Additionally, conductive tapes are used in electronics to provide electrical conductivity between components, highlighting the diverse functionalities of specialty tapes.

Applications of Anti-Slip Tape

Anti-slip tapes are specifically designed to enhance safety by providing a non-slip surface on various types of flooring. These tapes are commonly used in areas prone to slipping hazards, such as staircases, ramps, and wet environments. The surface of anti-slip tapes is typically coated with a rough, abrasive material that increases traction, reducing the risk of slips and falls.

In industrial environments, anti-slip tapes are used on machinery platforms, walkways, and loading docks to prevent accidents. These tapes are designed to withstand heavy foot traffic and harsh conditions, ensuring long-lasting performance. Anti-slip tapes are also available in various colors and patterns, including glow-in-the-dark options, to enhance visibility and further improve safety. The versatility and effectiveness of anti-slip tapes make them a crucial component in any safety protocol, providing a simple yet effective solution to prevent accidents.

Electrical Tape

Electrical tapes are specifically designed to insulate and protect electrical wires and connections. They are typically made from materials such as vinyl, rubber, or PVC, which provide excellent insulating properties and resistance to electrical currents. The adhesive used in electrical tapes is also formulated to maintain adhesion and flexibility over a wide range of temperatures, ensuring reliable performance in various conditions.

The structure of electrical tapes often includes a layer of flame-retardant material to enhance safety. This feature is crucial in preventing the spread of fire in case of electrical faults. Additionally, some electrical tapes are designed to be color-coded, allowing for easy identification of different wires and components. This simplifies the process of wiring and troubleshooting, making electrical tapes an essential tool for electricians and technicians.

Choosing the Right Electrical Tape

Selecting the right electrical tape depends on the specific requirements of the application. Factors such as the operating temperature, environmental conditions, and the type of electrical system must be considered. For instance, in high-temperature environments, standard electrical tapes may lose their insulating properties, leading to potential safety hazards. High-temperature electrical tapes, designed to withstand extreme heat, are essential in such conditions to ensure reliable performance and safety.

In environments exposed to moisture or chemicals, waterproof or chemical-resistant electrical tapes are necessary to maintain insulation and adhesion. These tapes are formulated to perform well under harsh conditions, preventing electrical faults and ensuring safety. Additionally, the thickness and flexibility of the tape should be considered, as these factors influence the ease of application and the effectiveness of the insulation.

Automotive Tape

Automotive tapes are designed to meet the demanding requirements of the automotive industry, providing solutions for bonding, sealing, and insulating various components. These tapes are used in a wide range of applications, from securing interior trim to bonding exterior parts. The types of automotive tapes include double-sided tapes, foam tapes, and specialized bonding tapes, each offering unique properties tailored for specific uses. Double-sided tapes are commonly used for attaching emblems and trims, providing strong adhesion without visible tape lines, while foam tapes offer cushioning and noise reduction.

The functions of automotive tapes extend beyond simple bonding. They are also used for vibration damping, soundproofing, and providing thermal insulation. For example, heat-resistant tapes are employed in engine compartments to protect components from high temperatures. Additionally, sealing tapes are used to prevent water and dust ingress, ensuring the durability and longevity of automotive parts.

Durability and Weather Resistance of Automotive Tapes

Durability and weather resistance are critical factors in the performance of automotive tapes. These tapes must withstand harsh conditions, including extreme temperatures, UV exposure, and varying humidity levels, to ensure long-lasting adhesion and functionality. Automotive tapes are designed to maintain their properties under these conditions, providing reliable performance throughout the life of the vehicle.

Weather-resistant automotive tapes are formulated with special adhesives and backing materials that resist degradation from environmental exposure. UV-resistant tapes prevent deterioration from prolonged sun exposure, while waterproof tapes maintain adhesion in wet conditions. These properties are essential in preventing issues such as peeling, cracking, or loss of adhesion, which can compromise the safety and functionality of automotive parts.

Masking Tape

Masking tape is a versatile adhesive tape used primarily for painting and surface protection. It is designed to provide clean, sharp lines when painting, preventing paint bleed and ensuring a professional finish. The adhesive on masking tape is formulated to stick well to surfaces while being easy to remove without leaving residue, making it ideal for temporary applications.

Beyond painting, masking tape is also used for labeling and bundling. Its ability to adhere to various surfaces, including paper, plastic, and metal, makes it useful for organizing and identifying items in homes, offices, and workshops. Masking tape can also be used for light-duty bundling, providing a simple solution for holding items together temporarily.

Using Different Widths of Masking Tape

Masking tape is available in various widths, allowing for precise application depending on the task. Narrow widths are ideal for detailed work, such as creating intricate designs or protecting small areas during painting. These tapes provide the precision needed for fine lines and curves, ensuring a clean and professional finish. Wider widths, on the other hand, are suitable for covering larger areas, reducing the need for multiple strips of tape and saving time during application.

The choice of masking tape width also depends on the surface and the type of paint being used. For rough or textured surfaces, wider tapes provide better coverage and adhesion, preventing paint from seeping underneath. Similarly, when using thick or heavy paints, wider tapes help in creating a clean edge without paint bleed.

Floor Tape

Floor tape is designed to withstand heavy foot traffic and harsh conditions, making it an essential tool for marking and organizing spaces in industrial, commercial, and residential settings. These tapes are typically made from durable materials such as vinyl or PVC, which provide excellent resistance to wear and tear. The adhesive used in floor tapes is formulated to offer strong adhesion to various surfaces, including concrete, wood, and metal, ensuring long-lasting performance even in high-traffic areas.

Floor tapes must adhere firmly to the surface to prevent lifting or peeling, which can pose tripping hazards. The adhesive should also be resistant to moisture, chemicals, and temperature variations, ensuring the tape remains in place under different environmental conditions. Additionally, some floor tapes feature a non-slip surface to enhance safety, providing extra traction in areas prone to slipping.

Proper Application of Floor Tape

The first step in the application process is to thoroughly clean the surface where the tape will be applied. Removing dirt, dust, and grease ensures the adhesive bonds properly to the surface, preventing premature lifting. It is also important to ensure the surface is dry before applying the tape, as moisture can weaken the adhesive and cause the tape to peel.

When applying the tape, it should be done in a smooth and consistent manner to avoid air bubbles and wrinkles. Using a roller or applying firm pressure helps to ensure the tape adheres evenly to the surface. For straight lines, using a chalk line or measuring tape can help in achieving precise application. In areas with curves or corners, cutting the tape at an angle can help in fitting the tape snugly around the bend without creating gaps.

After application, it is recommended to allow the tape to set for a few hours before exposing it to heavy foot traffic or cleaning. This curing time helps the adhesive to bond fully with the surface, ensuring long-lasting adhesion. Regular inspection and maintenance of the floor tape can also help in identifying and addressing any issues such as lifting or wear, ensuring the tape continues to perform effectively.

Packing Tape

Types of Packing Tape

There are several types of packing tape available, each designed for specific applications and environments. The most common types include acrylic packing tape, hot melt packing tape, and water-activated tape.

Acrylic packing tape is known for its clarity, UV resistance, and long-lasting adhesion. It is ideal for sealing boxes that will be stored for extended periods, as it does not yellow or degrade over time. This tape is also suitable for use in a wide range of temperatures, making it versatile for different shipping and storage conditions.

Hot melt packing tape, on the other hand, offers superior strength and quick adhesion. It is commonly used in high-volume packaging operations where speed and efficiency are crucial. This tape provides a strong bond to corrugated boxes, ensuring the packages remain sealed during transit. Hot melt packing tape is also resistant to moisture and temperature variations, making it suitable for various shipping environments.

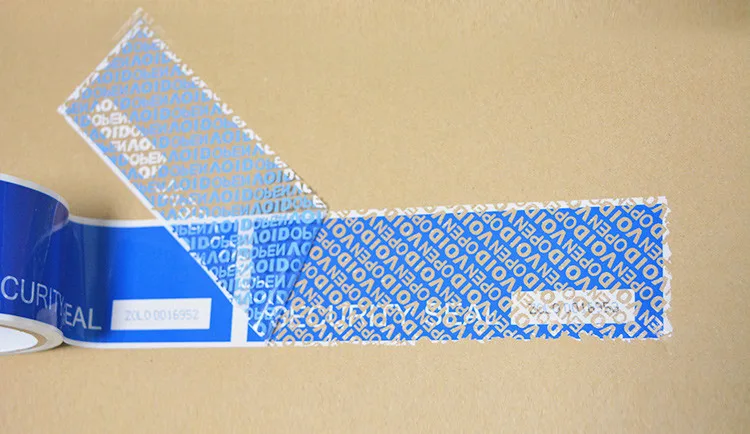

Water-activated tape, also known as gummed tape, is made from paper and features a water-activated adhesive. This tape forms a strong bond with the box when applied, providing tamper-evident sealing. It is often used for high-security packaging and is favored for its environmental benefits, as it is made from recyclable materials.

Choosing the Right Packing Tape for Efficient Packaging

Factors such as the weight of the package, the type of box, and the environmental conditions must be considered when choosing packing tape. For heavy or bulky packages, a stronger tape such as hot melt packing tape is recommended to provide the necessary support and adhesion. For packages that will be stored for long periods, acrylic packing tape offers the durability and UV resistance needed to maintain adhesion over time.

The type of box also influences the choice of packing tape. Corrugated boxes, which are commonly used for shipping, require tapes that can bond well with the textured surface. Hot melt and acrylic tapes are both suitable for this purpose, offering strong adhesion to corrugated material. For boxes made from recycled or rough materials, water-activated tape can provide a secure seal by penetrating the fibers of the box.

Environmental conditions such as temperature and humidity also play a role in selecting packing tape. For environments with extreme temperatures, such as cold storage or hot warehouses, acrylic packing tape is ideal due to its wide temperature range. In humid or wet conditions, moisture-resistant tapes like hot melt packing tape ensure the packages remain sealed and protected.

Duct Tape

Duct tape is renowned for its strength and versatility, making it a staple in both household and industrial settings. The structure of duct tape typically includes a polyethylene coating over a cloth or scrim backing, with a rubber-based adhesive. This construction provides a balance of strength, flexibility, and adhesion, allowing duct tape to perform effectively in a wide range of applications.

In household settings, its strong adhesive and durable backing make it ideal for patching holes, reinforcing objects, and bundling items. Duct tape’s ability to adhere to various surfaces, including wood, metal, plastic, and fabric, enhances its versatility for home use. It is also popular for temporary fixes in plumbing, automotive repairs, and sealing leaks, demonstrating its multifunctional capabilities.

In industrial settings it is commonly employed for sealing ductwork, hence its name, providing an airtight and durable seal. Duct tape is also used in construction for securing insulation, bundling cables, and marking hazardous areas. Its resistance to moisture, abrasion, and temperature variations makes it suitable for both indoor and outdoor use. The wide range of applications and reliable performance of duct tape underscore its importance as a versatile and essential tool.

Medical Tape

Types and Applications of Medical Tape

Medical tape plays a crucial role in healthcare settings, providing secure and gentle adhesion for wound dressings, bandages, and medical devices. There are several types of medical tapes available, each designed to meet specific needs in patient care. The most common types include hypoallergenic tape, cloth tape, and paper tape.

Hypoallergenic tape is designed for patients with sensitive skin or allergies. It features a gentle adhesive that minimizes the risk of skin irritation or allergic reactions, making it suitable for long-term use. Hypoallergenic tape is commonly used for securing dressings and bandages on patients with delicate skin, ensuring comfort and safety during healing.

Cloth tape, also known as surgical tape, is durable and flexible, making it ideal for securing bulky dressings and medical devices. This tape adheres well to skin and is easy to tear, facilitating quick and efficient application. Cloth tape is commonly used in surgical settings, orthopedics, and sports medicine for securing splints, braces, and other medical equipment.

Paper tape is lightweight and breathable, making it suitable for securing lightweight dressings and sensitive skin. It is hypoallergenic and gentle on the skin, minimizing the risk of irritation. Paper tape is often used in pediatric care, geriatrics, and for patients with fragile or sensitive skin conditions.

Safety and Comfort in Medical Tape Applications

Safety and comfort are paramount considerations when applying medical tape to patients. Proper technique and adherence to best practices help minimize the risk of complications and ensure optimal patient outcomes. Before applying medical tape, healthcare professionals should assess the patient’s skin condition and sensitivity to determine the most suitable type of tape.

Cleaning the skin with a gentle cleanser and allowing it to dry completely helps remove oils and debris that can interfere with tape adhesion. Avoiding excessive stretching of the skin during tape application reduces the risk of skin trauma and discomfort for the patient.

When securing dressings or medical devices with tape, healthcare professionals should ensure the tape is applied smoothly and evenly to promote adhesion. Pressing down gently on the tape ensures it conforms to the contours of the skin or dressing without causing wrinkles or gaps. Checking the tape regularly for signs of loosening or irritation allows for prompt adjustment or replacement to maintain secure and comfortable adhesion.

Removing medical tape requires gentle and careful technique to minimize discomfort and skin trauma. Slowly peeling back the tape at a low angle reduces the risk of skin tearing or irritation. Supporting the skin while removing the tape helps minimize discomfort and trauma, especially for patients with sensitive skin or fragile conditions.

What Types Of Adhesives Are Used For Tapes?

Adhesives play a significant role in determining the bonding strength, durability, and suitability of tapes for different environments and surfaces.

Rubber-Based Adhesives

Rubber-based adhesives are one of the oldest and most widely used types of adhesives in tapes. These adhesives are typically made from natural rubber or synthetic rubber compounds. They offer strong initial tack and adhesion to a variety of surfaces, including paper, plastic, and metal. Rubber-based adhesives are flexible and conformable, making them suitable for applications that require bonding to irregular surfaces or where some degree of flexibility is needed.

One of the key advantages of rubber-based adhesives is their ability to maintain adhesion in a wide range of temperatures. They perform well in both high and low-temperature environments, making them versatile for indoor and outdoor applications. However, rubber-based adhesives may soften or lose adhesion at elevated temperatures, which can limit their use in applications where heat resistance is critical.

Rubber-based adhesive tapes are commonly used in packaging, general-purpose bonding, and masking applications. They provide reliable adhesion and ease of use, making them a preferred choice for many everyday tasks.

Acrylic Adhesives

Acrylic adhesives are synthetic adhesives known for their durability, UV resistance, and versatility. These adhesives are formulated from acrylic polymers and offer excellent adhesion to a wide range of substrates, including plastics, metals, and glass. Acrylic adhesives provide superior resistance to aging, weathering, and chemicals, making them suitable for outdoor and harsh environment applications.

One of the primary advantages of acrylic adhesives is their temperature resistance. They maintain adhesion and performance over a broad temperature range, from very low to high temperatures, without softening or losing bond strength. This makes acrylic adhesive tapes ideal for automotive, construction, and industrial applications where exposure to varying temperatures is common.

Acrylic adhesive tapes are often used for permanent bonding, structural applications, and where long-term durability is required. They offer strong adhesion and stability over time, making them a reliable choice for demanding applications.

Silicone Adhesives

Silicone adhesives are known for their high temperature resistance, flexibility, and non-reactive properties. These adhesives are based on silicone polymers and offer excellent performance in extreme temperature environments, ranging from very low to high temperatures. Silicone adhesive tapes maintain flexibility and adhesion over a wide temperature range, making them suitable for applications where thermal stability is critical.

One of the key advantages of silicone adhesives is their ability to bond well with silicone substrates and other difficult-to-bond materials. They provide strong adhesion to smooth, non-porous surfaces such as glass, ceramics, and certain plastics. Silicone adhesive tapes are commonly used in aerospace, electronics, and medical applications where reliability under harsh conditions is essential.

Silicone adhesive tapes also offer excellent electrical insulation properties and resistance to moisture, chemicals, and UV exposure. These characteristics make them ideal for sealing and insulation applications where environmental protection and long-term performance are required.

Hybrid Adhesives

Hybrid adhesives combine characteristics of different adhesive types to achieve specific performance requirements. For example, hybrid tapes may combine the strength and initial tack of rubber-based adhesives with the durability and temperature resistance of acrylic adhesives. This allows manufacturers to tailor tapes for applications that require a balance of adhesive properties.

Hybrid adhesive tapes are often used in automotive, construction, and specialty applications where performance under diverse conditions is critical. They offer versatility and customized solutions for bonding, sealing, and mounting applications across various industries.

Factors to Consider When Choosing Adhesive for Your Tape

1. Substrate Type

The type of surface or substrate to which the tape will adhere is a primary consideration. Different adhesives perform differently on various materials such as plastics, metals, glass, and fabrics. For example, rubber-based adhesives typically adhere well to paper and cardboard surfaces but may struggle with plastics or oily metals. Acrylic adhesives, on the other hand, bond effectively to a wide range of substrates including metals, plastics, and glass.

2. Environmental Conditions

Environmental factors such as temperature, humidity, and exposure to UV light can affect adhesive performance. Acrylic adhesives are known for their excellent UV resistance and durability in outdoor applications, making them suitable for prolonged exposure to sunlight. Silicone adhesives excel in extreme temperatures and are resistant to moisture, making them ideal for sealing and insulation in challenging environments.

3. Bonding Requirements

Consider the specific requirements for bonding strength and permanence. Rubber-based adhesives offer strong initial tack and are suitable for applications where repositioning may be necessary. Acrylic adhesives provide durable bonds and are often used for permanent applications where high strength and reliability are essential. Hybrid adhesives combine attributes of different types to achieve specific performance characteristics tailored to unique bonding needs.

4. Application Method

The method of application, including whether the tape needs to be applied manually or with automated equipment, influences adhesive selection. Some adhesives are designed for easy dispensing and application, while others may require controlled environments or specific handling techniques to achieve optimal results.

Matching Adhesive Properties to Application Requirements

To select the right adhesive for your tape application, it’s essential to match the adhesive properties to your specific needs:

For Indoor Applications: Consider factors such as temperature stability and resistance to aging. Acrylic adhesives are often suitable due to their versatility and long-term durability.

- For Outdoor Applications: UV resistance, weatherability, and moisture resistance are critical. Acrylic adhesives with UV stabilizers or silicone adhesives are preferred for their ability to withstand prolonged exposure to environmental elements.

- For High-Temperature Environments: Silicone adhesives provide excellent heat resistance and maintain adhesion at extreme temperatures, making them ideal for automotive, aerospace, and industrial applications.

- For Medical or Skin Contact Applications: Hypoallergenic and gentle adhesives such as acrylic or silicone are preferred to minimize skin irritation and ensure patient comfort.

Utilizing Manufacturer Guidance and Technical Data

Manufacturers provide technical data sheets and guidance to assist in selecting the most suitable adhesive tape for specific applications. These resources detail adhesive properties, performance characteristics, and application recommendations based on testing and industry standards. Consulting with adhesive suppliers or manufacturers can provide valuable insights and ensure optimal tape performance in diverse applications.

Which Materials Are Used For The Backing Or Carrier?

The backing or carrier material of adhesive tapes plays a crucial role in determining their strength, flexibility, and suitability for various applications. Understanding the different materials used as tape backings helps in selecting the right tape for specific needs. Here, we’ll explore common materials used as backings and their characteristics:

Types of Backing Materials

1. Polyethylene (PE) and Polypropylene (PP)

Polyethylene and polypropylene are widely used for their lightweight and flexible properties. These materials offer good resistance to moisture and chemicals, making them suitable for packaging tapes and applications where flexibility and conformability are required. Polypropylene tapes are often preferred for their higher tensile strength compared to polyethylene.

2. PVC (Polyvinyl Chloride)

PVC tapes are known for their durability and resistance to abrasion and tearing. They offer good conformability to irregular surfaces and provide reliable performance in electrical insulation, floor marking, and color coding applications. PVC tapes are available in various colors and thicknesses to meet specific needs for visibility and marking purposes.

3. Cloth (Fabric) Backings

Cloth or fabric backings are used for their strength and versatility. These tapes typically feature a woven or non-woven fabric substrate, coated with adhesive for enhanced durability and adhesion. Cloth tapes are tear-resistant and offer high tensile strength, making them ideal for applications requiring strong, durable bonds such as carpet seaming, bookbinding, and heavy-duty repairs.

4. Paper Backings

Paper tapes are lightweight and economical, offering good conformability to surfaces and ease of handling. These tapes are commonly used in painting and masking applications, where clean removal without residue is important. Paper tapes are available in different grades and adhesive strengths to suit various masking and packaging needs.

Considerations When Selecting Backing Materials

Strength and Durability

Choose a backing material that provides adequate strength and durability for the intended application. For heavy-duty applications, such as construction or industrial repairs, cloth or reinforced tapes offer superior strength and tear resistance. For lightweight applications like packaging and labeling, polyethylene or paper tapes may be sufficient.

Flexibility and Conformability

Backings with high flexibility and conformability are essential for applications where the tape needs to adhere to irregular surfaces or contours. Polyethylene and cloth tapes provide good conformability, while PVC tapes offer flexibility combined with durability for versatile applications.

Environmental Compatibility

Consider the environmental conditions where the tape will be used. PVC tapes are suitable for indoor and outdoor applications due to their weather resistance and durability. Polyethylene and polypropylene tapes offer good moisture resistance, making them suitable for packaging and sealing in humid conditions.

Application-Specific Requirements

Tailor the choice of backing material to meet specific application requirements, such as color coding, electrical insulation, or surface protection. PVC tapes are available in a range of colors for identification and marking purposes, while cloth tapes provide robust adhesion for repairs and industrial applications.

Conclusion

Choosing the right adhesive tape involves considering factors such as adhesive type, backing material, environmental conditions, and application-specific requirements. Whether you need a tape for securing packages in transit, marking safety zones in industrial settings, or providing gentle adhesion in medical applications, selecting the appropriate tape ensures optimal performance and reliability.

As a leading adhesive tape manufacturer, we at UW Tape pride ourselves on delivering high-quality products tailored to meet the exacting demands of our customers. With over twelve years of expertise in custom tape production and state-of-the-art facilities, including specialized R&D laboratories, we are committed to innovation and excellence in tape manufacturing.

For all your adhesive tape needs, trust UW Tape to provide solutions that adhere to the highest standards of quality, durability, and performance. Contact us today to discover how our extensive range of tapes can benefit your specific applications and requirements.