Did you know that nearly 20% of manufacturing downtime is linked to packaging issues? Packaging operations, particularly carton sealing, encompass a variety of challenges that can impact workflow and ultimately affect your bottom line. In this article, we’ll dive into the key issues manufacturers face, explore the causes of tape waste, uncover hidden costs associated with packing tape, and discuss how these challenges can lead to substantial downtime within production lines.

What Are the Key Issues Manufacturers Face with Carton Sealing?

Production Malfunctions

One of the most pressing problems faced during carton sealing involves production malfunctions. Common issues include tape failing to adhere properly to cartons, broken tape, and uncut tape. Each of these complications can lead to significant downtime as teams scramble to assess and resolve the situation. This not only results in wasted materials but also increases labor costs due to the need for resealing and reworking improperly sealed cartons.

Unsecure Seals

Unsecure seals represent another major concern in packaging operations. When improper tape application occurs, or when the wrong type of tape is used for the job, cartons become at risk of opening during storage or transit. This not only puts the products inside at risk of damage or contamination but also opens the door to theft. Flimsy seals can make it far too easy for pilferers to tamper with the contents, leading to further losses for manufacturers.

Product Damage from Sharp Objects

Product damage caused by sharp objects, like knives and blades, often goes overlooked in the discussion of carton sealing. Typically, these incidents occur upon receiving the cartons rather than during packaging or shipping. However, even minor nicks and cuts can render products unsaleable. The financial impact can be severe for manufacturers, as unsaleable products directly contribute to losses that could have been avoided with proper handling and sealing practices.

What Causes Packing Tape Waste in Manufacturing?

Sources of Tape Waste

Many manufacturers accept tape waste as a customary part of their operations, often overlooking this issue. However, when packing tape isn’t “Good to the Core”—meaning it’s not usable down to the cardboard core—it leads to unnecessary waste. This waste typically accumulates as stub rolls, which often end up discarded or are utilized for manual rework when a seal fails. Unfortunately, when stub rolls become too large, they cannot fit onto hand dispensers, compounding the disposal problem.

Mechanical Failures

Mechanical failures stand out as a primary cause of packing tape waste. Various factors can contribute to these failures, but the most significant include high unwind force, poor winding practices, and misadjusted tension settings on tape applicators. Each of these mechanical issues can lead to production delays, the need for corrective measures, and ultimately, wasted materials that could have been used more effectively.

Operator Convenience

Operator convenience can also contribute to packing tape waste in unexpected ways. Often, operators switch the tape roll prematurely to avoid running out of tape. While this proactive approach might seem beneficial at first, it creates stub rolls that frequently go unused. These leftover rolls can ultimately add to the wasted materials on the production line.

Improper Tape Application

Improper application of packing tape presents another significant source of waste. If operators do not deliver adequate wipe-down pressure while applying the tape, the seals on cartons may not hold effectively. This inadequate adhesion can lead to substantial consequences, including the need for rework, which adds to labor costs. Moreover, to compensate for weak seals, operators may resort to using multiple strips of tape, further increasing waste.

What Are the Hidden Costs of Packaging Tape?

Financial Implications

The concept of hidden costs in packaging tape operations is crucial for manufacturers to consider. The impact of packing tape inefficiencies can be felt across several key areas:

Productivity and Overall Equipment Effectiveness (OEE)

Slow tape roll changeovers, tape not functioning down to the core, and the need for reworks due to tape-related issues can significantly disrupt operational efficiency. Frequent stoppages on the production line to resolve these issues can lead to diminished productivity levels.

Waste and Environmental Impact

When packing tape fails to run down to the core, the leftover stub rolls can accumulate rapidly. This waste represents not only financial losses but also considerable environmental consequences due to the material ending up in landfills. The phrase “reduce, reuse, recycle” comes to mind as we consider sustainable practices in manufacturing. But if the packaging tape is eco-firendly, like a biodegradable packing tape, it will reduce the environmental impact at the most extent.

Worker Safety

Using sharp objects to open cartons presents a serious risk of injury to employees. Even minor cuts from knives can accrue costs upwards of $40,000 due to medical expenses and lost productivity. Opting for packing tape or application methods that allow seals to be opened by hand reduces this risk substantially.

Downtime and Rework Labor

When production halts to address slow tape roll changeovers or issues such as broken tape, it leads to costly downtime. This might involve reworking taped cartons or hand-taping cases, both of which slow down productivity.

Customer Perception

If tape fails to stick during transit and storage, customers are left with a negative impression of the brand. Unsecure seals can lead to product damage or loss, ultimately resulting in customer complaints and returns, which tarnish your company’s reputation.

Content Security

Packing tape that does not adhere appropriately poses a direct threat to product security. Insecure seals make it easy for thieves to pilfer items without leaving evidence.

How Does Tape Cause Downtime on the Packaging Line?

The Impact of Downtime

Downtime refers to periods during which a system fails to perform, resulting in production interruptions. This significant issue is a hot topic among manufacturers. Not only does downtime cause production halts, but it also leads to missed deadlines and lost profits. Additionally, the stress and frustration experienced at all levels of manufacturing increases, exacerbating inefficiencies and driving up product costs associated with reworks, labor overhead, and material waste.

Essential Tasks: The Costly Necessities

Everyday tasks are unavoidable, yet they can be time-consuming and costly. In the context of packaging operations, one such critical task is the tape roll changeover. Operators frequently need to halt production to thread a new roll. This process can take several minutes to complete. Navigating difficult thread paths on tape applicators or correcting errors from improperly threaded tape can create bottlenecks, prolonging downtime and increasing operator stress.

Mechanical Failures

Mechanical failures often cause significant downtime on the packaging line. These failures can stem from malfunctioning tape applicators, leading to issues such as poor adhesion, uncut tape, or broken tape. When packing tape fails to adhere properly, operators must stop the line or slow production while they address the issue.

During this downtime, employees often resort to hand-taping cases, leading to labor-intensive and inefficient processes.

Uncut Tape

Uncut tape presents a similar challenge. It can trigger a chain reaction that involves stopping production, cleaning up, and reworking improperly sealed cases. This scenario not only consumes time but also heightens frustration among workers.

Broken Tape

Additionally, broken tape or tape that doesn’t run down to the core typically results from poor tension control, which can put excessive pressure on the tape. This condition causes breakage and stretching. As a result, operators must stop the machine for adjustments or roll changes, leading to wasted tape and lost efficiency.

Case Jams

Case jams can also lead to productivity losses. Although often caused by flap folders, these jams typically occur at the tape applicator stage due to improperly positioned major flaps. Such jams halt production and can inflict significant damage to machinery, further increasing the risk of future occurrences.

Strategies to Address Downtime

Manufacturers prioritize addressing downtime to enhance overall equipment effectiveness (OEE), which reflects machine availability, performance, and quality. Improving OEE enables manufacturers to increase production while utilizing fewer resources.

Training is one effective strategy to mitigate downtime-related issues. Ensuring that your workforce is equipped with the proper knowledge and tools can significantly alleviate stress and inefficiency.

Selecting the Right Equipment

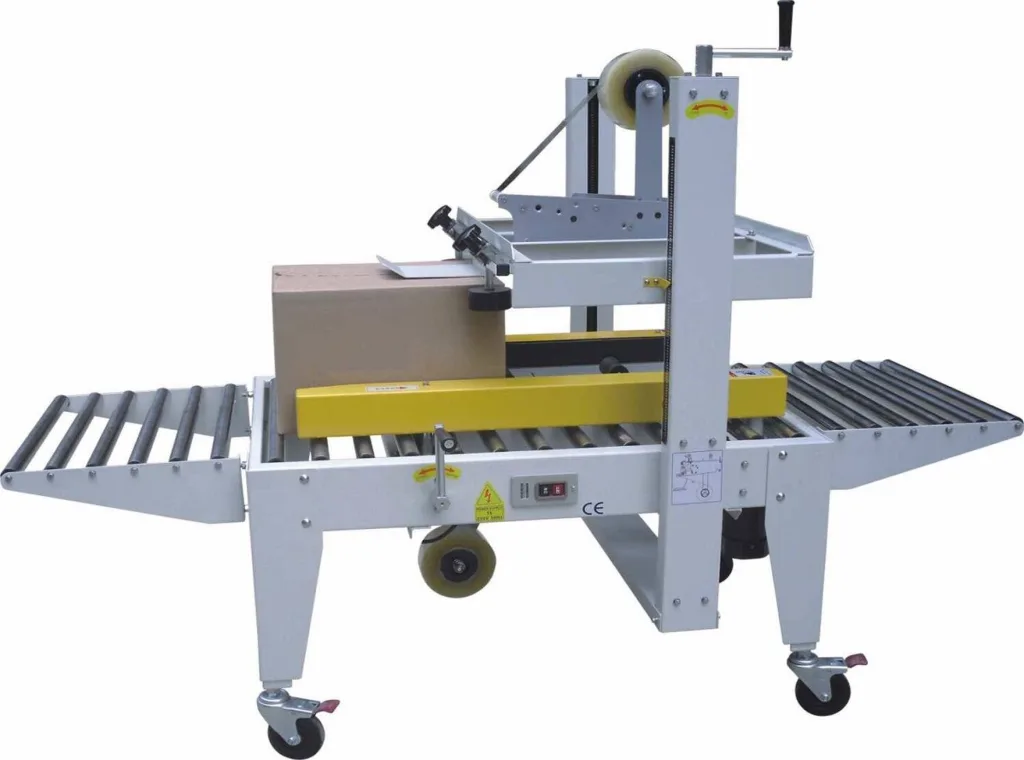

Selecting the right equipment is essential to a successful packaging line. This choice includes finding an optimal combination of packing tape and the right tape applicator. Additionally, understanding your specific operating environment—such as temperature, weight, size of cartons, and contents—helps inform decisions regarding the appropriate tape formulation and application type.

Related article: Techincal insights for packaging tape.

Conclusion

The challenges in packaging operations, particularly in carton sealing, can have far-reaching consequences on overall efficiency, cost management, and brand reputation. By addressing the key issues of production malfunctions, tape waste, and the hidden costs of packing tape, manufacturers can significantly improve their operational efficacy. At Fonitaniya Adhesive Tape, we pride ourselves on over 15 years of experience as an adhesive solution provider. Our innovative packing tape is designed to tackle these challenges head-on, ensuring secure seals and reliable performance throughout the packaging supply chain.

FAQs

What types of packing tape are best for carton sealing?

Choose packing tape that suits your specific application standards, such as heavy-duty or water-activated options.

How can I reduce tape waste in my packaging operations?

Implement good tape management practices, such as using tape that adheres to the cardboard core.

Why is proper application of packing tape important?

Inadequate application can lead to unsecure seals, wasted materials, and increased labor costs.

What are the safety concerns with packing tape?

Using sharp objects to open packages may lead to employee injuries and associated costs.

How often should I perform maintenance on tape applicators?

Regular maintenance checks can help ensure tape applicators function properly and minimize downtime risks.