Phase change materials (PCMs) are advanced thermal interface materials engineered to absorb and release latent heat as they transition between solid and liquid forms. In cooling systems, they regulate temperature by storing excess heat during peak operation and releasing it when the system cools.

Used in battery cooling, electronics, and building temperature management, PCMs offer enhanced thermal buffering compared to conventional interface materials.

What Is the Phase Change Material for Cooling Batteries?

For battery applications, PCMs are selected to maintain cells within optimal temperature ranges, improving safety, performance, and longevity. An effective PCM for battery cooling combines good thermal conductivity with stable phase-change behavior near operating temperatures.

Examples of Phase Change Materials

Common PCMs include organic paraffins, salt hydrates, fatty acids, and proprietary formulations for electronic cooling. Each type offers a trade-off between conductivity, melting point, and containment requirements.

What Is Free Cooling of Buildings with PCMs?

Free cooling uses PCMs embedded in building materials to store night-time ambient coolness and release it during warm periods, reducing HVAC load. It’s a passive thermal management strategy that improves energy efficiency.

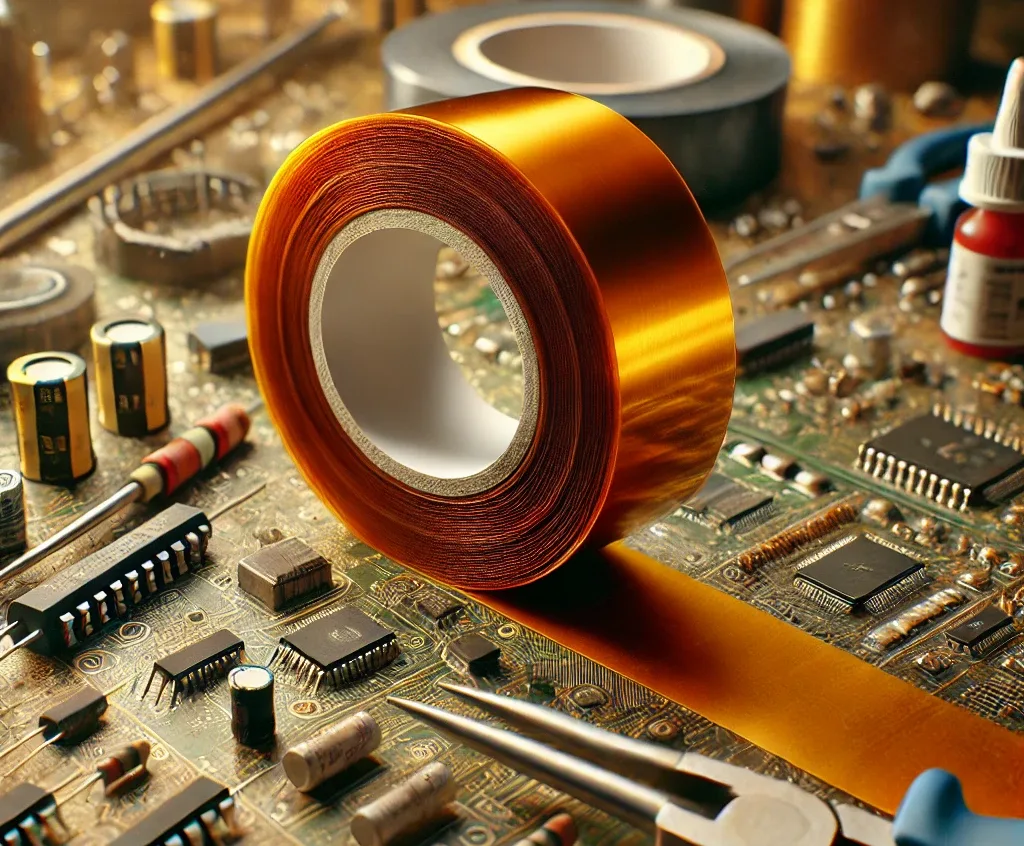

Introducing Fonitaniya Phase‑Change Material for Cooling (FON‑10112)

The Fonitaniya FON-10112 series is a phase-change thermal pad designed to excel in thermal interfaces between heat sinks and high-power components. Its features include:

- Thermal conductivity of 1.5–5.5 W/m·K (Hot Disk method)

- Silicone-free, low-contamination composition

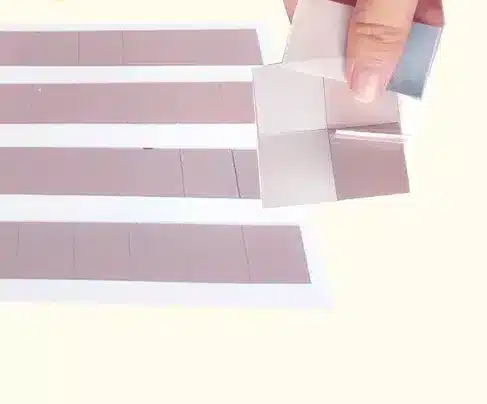

- Self‑adhesive, low-viscosity material in sheet or roll form

- Extremely low thermal resistance and easy customization

Key Benefits and Features

- Superior heat transfer via phase-change thermal cycling

- Environmental safety with a silicone-free formulation

- Clean application thanks to self-adhesion and no messy paste

- Custom form factor to fit CPUs, power modules, and heat sinks

Technical Attributes

| Attribute | Value |

|---|---|

| Thermal Conductivity | 1.5–5.5 W/m·K |

| Form Factor | Sheet or Roll |

| Adhesive | Self-adhesive, low viscosity |

| Thermal Resistance | Extremely Low |

| Free of Silicone | Yes |

| Serial Number | FON‑10112 |

Comparison: Phase‑Change Material vs Standard Thermal Interface Material

Here’s how FON‑10112 compares with a conventional material:

| Feature | Phase‑Change Material | Standard Paste or Pad |

|---|---|---|

| Conductivity | 1.5–5.5 W/m·K | Usually 1–3 W/m·K |

| Ease of Application | Self‑adhesive sheet | Messy paste or alignment needed |

| Thermal Resistance | Very low due to phase-change | Higher |

| Cleanup | Minimal | May require alcohol cleaning |

| Reusability | Stable over time | Can degrade or shift |

| Contamination Risk | Low | Medium to high |

| Custom Form | Easily trimmed or cut | Usually fixed shapes |

How to Use and Maintain It

- Clean both mating surfaces before application.

- Cut to size and apply directly; adhesive bonds instantly.

- Operate across −45 °C to 200 °C reliably.

- To remove, gently peel and if needed warm slightly for easier detachment.

- Dispose in accordance with material safety guidelines; silicone‑free composition makes it environmentally safer.

Why Use It in Electronics and Thermal‑Critical Systems?

This phase‑change material is ideal for:

- High‑power CPUs, GPUs, and power modules

- Smart electronics where compact thermal design matters

- Automotive ECUs, inverters, and power electronics

- Devices requiring stable performance under thermal cycling

FAQs

Q1: What is thermal gel used for?

A: (Not applicable to PCM; see thermal paste/gel) – but PCM stores and releases latent heat for efficient thermal buffering.

Q2: How to remove PCM?

A: Peel gently; warm lightly if bonded strongly; clean with isopropyl alcohol if needed.

Q3: What is the difference between PCM and paste?

A: PCM solidifies into a stable interface, stores and releases latent heat, and is easier to apply; paste remains fluid, requires re‑application, and may spread.

Q4: Can paste replace this PCM?

A: Paste may work in basic systems, but cannot match phase-change benefits like latent heat storage and low resistance.

Q5: Examples of PCMs?

A: Paraffin wax, salt hydrates, fatty acid blends—but these general types may not offer adhesive or high-performance interface benefits.

Q6: Are PCMs used in building cooling?

A: Yes—they can be embedded in walls or ceilings to reduce HVAC usage via passive thermal storage.

Conclusion

Phase change thermal materials like FON-10112 provide a clean, reliable, and highly efficient cooling interface for modern electronics. They outperform traditional pastes and pads in conductivity, ease of use, and environmental safety.

For applications demanding low thermal resistance, high yield, and simple implementation, Fonitaniya delivers this phase-change solution tailored to smart devices, CPUs, heat sinks, and thermal-critical modules.