Heat Dissipation Insulation High Temperature Resistant Glass Fiber Double-sided Tape

Quick Details

Origin: Guangdong, China

Adhesive surface: Double-sided

Color: White/Black (customizable)

Features: High temperature resistance, insulation, thermal conductivity

Adhesive: Acrylic

Tube core: 3.0’’

Applications:

1. Integrated circuit packaging thermal conductivity

2. Heat sink-thermal interface accessories

3. Battery thermal management

4. LED lighting thermal management

5. Heat sink-thermal interface-non-adhesive

6. Flexible bonding

7. Thermal interface-damping-buffering

Product Features:

1. Good stability, can effectively improve and process die cutting and lamination.

2. High viscosity provides excellent adhesion for a variety of surfaces.

3. Good temperature resistance, thermal conductivity, and insulation performance

4. Application areas: used for bonding and heat dissipation of components such as LED light strips and electronic components.

| Technical Parameters | Product Number | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HMF 050/100 | HMF 050/150 | HMF 010/200 | HMF 010/250 | HMF 010/300 | HMF 010/350 | HMF 010/380 | HMF 010/400 | HMF 010/500 | HMF 010/700 | |

| Total thickness (mm) | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | 0.35 | 0.38 | 0.40 | 0.50 | 0.70 |

| Substrate thickness (mm) | 0.05 | 0.05 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Adhesion to Stainless Steel 0.5H RT (kg/25mm) | ≥1.2 | ≥1.2 | ≥1.5 | ≥1.5 | ≥1.5 | ≥1.5 | ≥1.8 | ≥1.8 | ≥1.8 | ≥2.0 |

| Initial tack (#) | ≥2# | ≥2# | ≥2# | ≥2# | ≥3# | ≥3# | ≥3# | ≥3# | ≥3# | ≥3# |

| Room temperature retention (H) | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H | ≥48H |

| Long-term temperature resistance (°C) | 80°C | 80°C | 80°C | 80°C | 80°C | 80°C | 80°C | 80°C | 80°C | 80°C |

| Short-term temperature resistance (°C) | 120°C | 120°C | 120°C | 120°C | 120°C | 120°C | 120°C | 120°C | 120°C | 120°C |

| Thermal conductivity (w/mk) | 0.3~0.8 | |||||||||

The above data is for reference only. If you have any questions about the product, please contact the relevant personnel of our company for detailed explanation and service. All products can be customized in different thicknesses according to customer requirements.

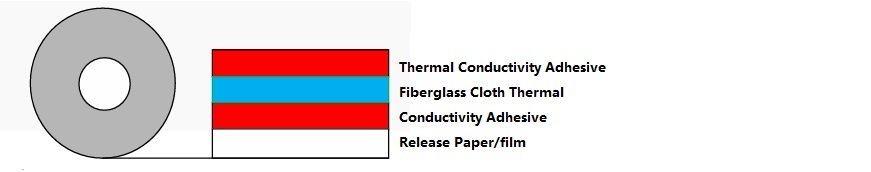

Product Structure:

Application:

1. Electronics: Double-sided thermal tape is widely used for electronic heat dissipation. It is often used to attach heat sinks to electronic components (such as CPUs, GPUs, and other high-performance chips).

2. LED lighting: LED lights generate heat during operation, and the use of double-sided thermal tape is essential to ensure proper heat dissipation. It is used to attach heat sinks to LED light strips and other LED components.

3. Automotive industry: Double-sided thermal tape is used in the automotive industry for a variety of applications, such as attaching heat sinks to engine components, attaching sensors to exhaust pipes, and attaching thermal insulation to various parts of the car.

4. Aerospace industry: In the aerospace industry, double-sided thermal tape is used to attach heat shields to spacecraft and satellites, attach thermal insulation to various parts of spacecraft, and attach heat sinks to electronic components.

5. Medical devices: Double-sided thermal tape is used in medical devices to attach temperature-sensitive sensors to patients, heat sinks to medical devices, and thermal insulation to various parts of medical devices.

6. HVAC Systems: Double-sided thermal tape is used in HVAC systems to attach insulation to pipes and ductwork, to attach radiators to HVAC components, and to attach temperature sensors to various parts of the system.

7. Construction: Double-sided tape is used in construction to install insulation on walls, roofs, and floors, as well as to install insulation on doors and windows.

If you want to customize tapes of other specifications, you can contact us to customize the specifications you want.

When can I get my quotation?

We will provide you with a detailed quotation as soon as we receive your inquiry. Typically, we will send you a quote within 24 hours. If your requirements are complex or need custom services, it might take a bit longer, but we will keep you informed of the progress promptly.

What is your order schedule?

After confirming your order, we will schedule production based on your requirements and our production plan. Generally, the production cycle for standard orders is 2-3 weeks. If you have an urgent order, please contact us as soon as possible. We will do our best to accommodate your request and arrange expedited production.

Can I get samples?

Yes, we are happy to provide samples for you. Please contact our sales team with your specific needs and sample type, and we will arrange for the samples to be sent to you as soon as possible. Some samples may require a small fee, but in most cases, we offer free samples for testing and evaluation.

Can I print my logo on the tape?

Absolutely. We offer customization services and can print your logo on the tape according to your requirements. Please provide a high-quality logo file and specific printing requirements. Our design team will create a draft design for your approval. We will also provide samples for you to confirm before production.

What if I don't have detailed requirements?

If you are unsure about the specific requirements, our technical team is more than happy to offer professional advice. Just tell us your application scenario and basic needs, and we will recommend the most suitable tape solution based on our extensive experience and wide range of products. We can also provide sample testing to ensure our products meet your needs.