High Temperature Kapton Tape

- High temperature resistance up to 280°C (536°F).

- Superior electrical insulation with breakdown voltage up to 10.5 KV.

- Chemically resistant to acids, alkalis, and solvents.

- Strong adhesion and durable mechanical strength for industrial use.

Attributes and Variation of Dielectric Polyimide Tape

| Attribute | Value |

|---|---|

| Brand | Fonitaniya |

| Serial Number | FON-10050 |

| Color | Amber |

| Total Thickness | 0.03mm (0.00118 in), 0.04mm (0.00157 in), 0.06mm (0.00236 in), etc. |

| Backing Thickness | 0.0125mm (0.00049 in), 0.025mm (0.00098 in), etc. |

| Backing Material | Polyimide (PI) |

| Adhesive | Silicone, Acrylic |

| Peel Strength | 4-7 N/inch |

| Tensile Strength | 10-36 kg/25mm |

| Elongation | 30%-70% |

| Breakdown Voltage | 2.5-10.5 KV |

| Temperature Resistance (Long-Term) | Up to 260°C (500°F) |

| Temperature Resistance (Short-Term) | Up to 280°C (536°F) |

Model Variation of Kapton Tape

| Model | Total Thickness [mm] | Backing Thickness [mm] | Backing | 180° Peel Strength [N/inch] | Tensile Strength [kg/25mm] | Elongation At Break [%] | Breakdown Voltage [KV] | Long-Term Temperature Resistance [℃] | Short-Term Temperature Resistance [℃] |

|---|---|---|---|---|---|---|---|---|---|

| FON-10050-30 | 0.03 | 0.0125 | PI | 4 | 10 | 30 | 2.5 | 260 | 280 |

| FON-10050-40 | 0.04 | 0.025 | PI | 4 | 10 | 45 | 5 | 260 | 280 |

| FON-10050-60 | 0.06 | 0.025 | PI | 5 | 10 | 45 | 5 | 260 | 280 |

| FON-10050-65 | 0.065 | 0.025 | PI | 6 | 10 | 45 | 5 | 260 | 280 |

| FON-10050-70 | 0.07 | 0.025 | PI | 6 | 10 | 45 | 5 | 260 | 280 |

| FON-10050-80 | 0.08 | 0.05 | PI | 5 | 20 | 55 | 7 | 260 | 280 |

| FON-10050-100 | 0.1 | 0.05 | PI | 6 | 20 | 55 | 7 | 260 | 280 |

| FON-10050-120 | 0.12 | 0.075 | PI | 6 | 28 | 60 | 9 | 260 | 280 |

| FON-10050-150 | 0.15 | 0.1 | PI | 7 | 36 | 70 | 10.5 | 260 | 280 |

| FON-10050-60A | 0.06 | 0.025 | PI | 7 | 10 | 45 | 5 | 100 | 150 |

| FON-10050-60E | 0.06 | 0.025 | PI | 5 | 10 | 45 | 5 | 260 | 280 |

Product Description of Polyimide Tape

Kapton tape, also known as polyimide tape or PI tape, is an industrial-grade adhesive tape made from polyimide film and coated with a high-performance silicone pressure-sensitive adhesive. Renowned for its outstanding thermal stability and electrical insulation properties, it can withstand high temperatures up to 280°C (536°F) and maintain reliable performance in demanding environments.

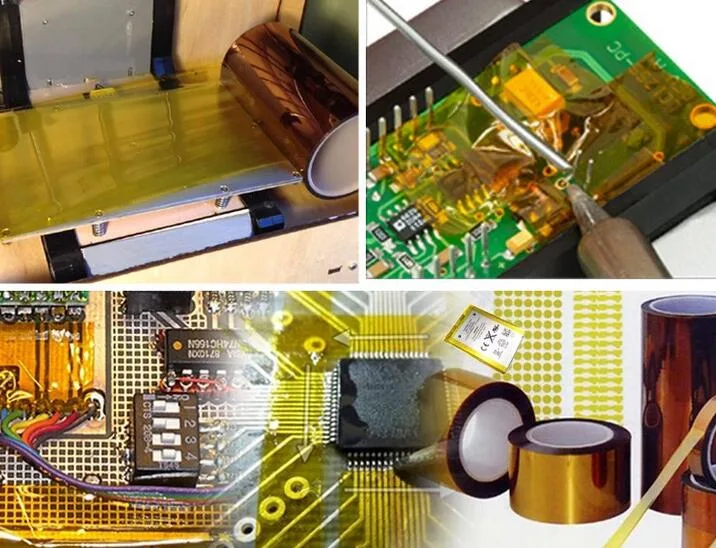

This tape is commonly used in electronic circuit board manufacturing, motor and transformer wrapping, aerospace insulation, and chemical industry applications. Its versatility and strong chemical resistance make it ideal for tasks ranging from wave soldering protection to high-temperature cable insulation.

Application

- Electronic Circuit Board Manufacturing: Protects components during wave soldering and shields gold fingers from solder splash.

- SMT Temperature Protection: Suitable for PCB, switches, and component protection under high temperatures.

- Motor and Transformer Manufacturing: Insulates motor coils and secures high-temperature coil ends.

- Aerospace and Automotive: Used for high-temperature, corrosion-resistant insulation and sealing.

- Power and Energy Industry: Insulates cables and measures furnace temperature during SMT processes.

- Chemical and Pharmaceutical: Provides reliable sealing and protection against chemical erosion.

- Special Applications: Die-cut for custom shapes, ideal for IC soldering protection.

If you want to customize tapes of other specifications, you can contact us to customize the specifications you want.

When can I get my quotation?

We will provide you with a detailed quotation as soon as we receive your inquiry. Typically, we will send you a quote within 24 hours. If your requirements are complex or need custom services, it might take a bit longer, but we will keep you informed of the progress promptly.

What is your order schedule?

After confirming your order, we will schedule production based on your requirements and our production plan. Generally, the production cycle for standard orders is 2-3 weeks. If you have an urgent order, please contact us as soon as possible. We will do our best to accommodate your request and arrange expedited production.

Can I get samples?

Yes, we are happy to provide samples for you. Please contact our sales team with your specific needs and sample type, and we will arrange for the samples to be sent to you as soon as possible. Some samples may require a small fee, but in most cases, we offer free samples for testing and evaluation.

Can I print my logo on the tape?

Absolutely. We offer customization services and can print your logo on the tape according to your requirements. Please provide a high-quality logo file and specific printing requirements. Our design team will create a draft design for your approval. We will also provide samples for you to confirm before production.

What if I don't have detailed requirements?

If you are unsure about the specific requirements, our technical team is more than happy to offer professional advice. Just tell us your application scenario and basic needs, and we will recommend the most suitable tape solution based on our extensive experience and wide range of products. We can also provide sample testing to ensure our products meet your needs.