Low VOC Double-Sided Tape

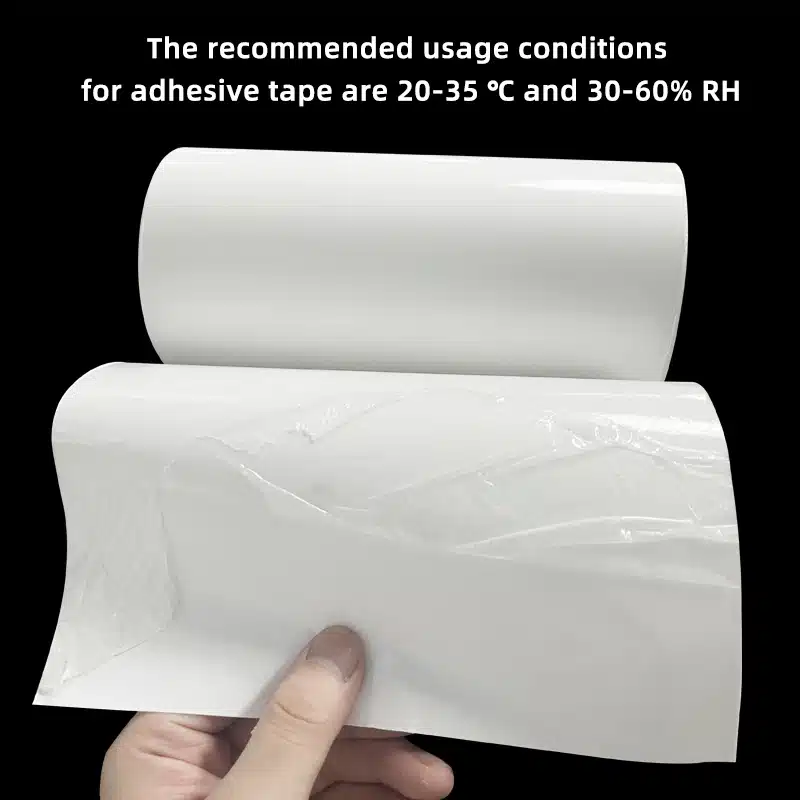

This low VOC cotton paper double-sided tape uses a water-based acrylic adhesive coated on high-permeability tissue paper. It offers:

- Excellent initial tack and durability

- Low-temperature bonding capability

- High resistance to plasticizers

- Dimensional stability and easy die-cutting

- Long-term temperature resistance: –40 °C to 100 °C; short-term up to 120 °C

Key performance highlights:

- 180° Peel Strength: SUS304 – 15.16 N/25 mm, PP – 17.22 N/25 mm, ABS – 9.17 N/25 mm

- Ball tack number: >15

- High-temperature holding power: >100 h at 80 °C with <3 mm displacement

- Warm water resistance: No debonding after 72 h at 80 °C

What is Low VOC double-sided tape?

Low VOC double-sided tape is a pressure-sensitive adhesive tape coated on both sides of a carrier, designed to form strong, permanent bonds while releasing minimal volatile organic compounds (VOCs). These tapes are critical in industries such as automotive, rail transit, appliances, and electronics, where air quality and long-term durability are essential.

How double-sided tape works

The principle is simple but powerful:

- Surface wetting – The adhesive flows into microscopic surface irregularities when pressure is applied.

- Molecular bonding – The adhesive forms physical and chemical bonds with the substrate.

- Carrier support – The internal tissue, film, or foam layer adds stability for easier processing and die-cutting.

Low VOC tapes achieve this with water-based acrylic adhesives instead of solvent-based ones, drastically reducing emissions.

Why VOC emissions matter

High VOC adhesives can cause:

- Interior fogging on vehicle glass

- Strong odors in enclosed spaces

- Potential health risks (eye irritation, headaches)

- Non-compliance with environmental regulations (e.g., VDA 278, GB 27630)

Advanced Low VOC tapes can meet Level A VOC performance under T/CAS281-2017 and record ND (Not Detected) for styrene, xylene, benzene, toluene, and other harmful compounds.

Types of Low VOC double-sided tape

- Film-based – PET/PP film carriers for precision mounting

- Tissue-based – Nonwoven carriers for flexibility

- Foam-based – PE/PU foam carriers for gap filling and vibration damping

- Scrim-reinforced – Mesh carriers for high tensile strength

Types of Low VOC double-sided tape

- Bonding rail transit thermal insulation and vibration absorption materials (e.g., melamine cotton, flame-retardant EVA panels)

- Rolling or pairing PU foam (density <50 kg/m³) to meet high temperature/humidity resistance

- Fixing PVC and cloth-based protective sheets

- Bonding automotive wiring harness silencer sponges

- Attaching thermal insulation sponges for automotive AC vents and ducts

- Laminating NVH foam materials like PU, PE, EPDM, and PP

- Fixing silencer materials in household appliances

Key technical specifications

| Parameter | Value | Test Method |

|---|---|---|

| Tape thickness | 0.135 ± 0.005 mm | – |

| Adhesive type | Water-based acrylic | – |

| Carrier | 12 g high-permeability tissue | – |

| Release liner | 110 g PEK paper | – |

| Peel adhesion (SUS304) | 15.16 N/25 mm | GB/T 2792-2014 |

| Peel adhesion (PP) | 17.22 N/25 mm | GB/T 2792-2014 |

| Peel adhesion (ABS) | 9.17 N/25 mm | GB/T 2792-2014 |

| Ball tack | >15 | GB/T 4852-2002 |

| Holding power @80 °C | >100 h, <3 mm displacement | Internal spec |

| Temperature resistance | –40 °C to 100 °C (long-term) / 120 °C (short-term) | – |

| VOC rating | Level A (ND for major hazardous VOCs) | T/CAS281-2017 |

How to choose the right tape

- Match carrier type to application – Tissue-based for flexibility, film-based for stability

- Check adhesion values – Ensure compatibility with target materials (PP, ABS, metals)

- Consider environmental exposure – High resistance is important for heat and moisture conditions

- Verify VOC compliance – Always request test reports for regulated industries

If you want to customize tapes of other specifications, you can contact us to customize the specifications you want.

When can I get my quotation?

We will provide you with a detailed quotation as soon as we receive your inquiry. Typically, we will send you a quote within 24 hours. If your requirements are complex or need custom services, it might take a bit longer, but we will keep you informed of the progress promptly.

What is your order schedule?

After confirming your order, we will schedule production based on your requirements and our production plan. Generally, the production cycle for standard orders is 2-3 weeks. If you have an urgent order, please contact us as soon as possible. We will do our best to accommodate your request and arrange expedited production.

Can I get samples?

Yes, we are happy to provide samples for you. Please contact our sales team with your specific needs and sample type, and we will arrange for the samples to be sent to you as soon as possible. Some samples may require a small fee, but in most cases, we offer free samples for testing and evaluation.

Can I print my logo on the tape?

Absolutely. We offer customization services and can print your logo on the tape according to your requirements. Please provide a high-quality logo file and specific printing requirements. Our design team will create a draft design for your approval. We will also provide samples for you to confirm before production.

What if I don't have detailed requirements?

If you are unsure about the specific requirements, our technical team is more than happy to offer professional advice. Just tell us your application scenario and basic needs, and we will recommend the most suitable tape solution based on our extensive experience and wide range of products. We can also provide sample testing to ensure our products meet your needs.