Thermal Gap Filler

- Enhances thermal conductivity while minimizing air gaps in electrical components.

- Dual-component design supports room temperature or heat-accelerated curing.

- Exceptional adhesive strength (up to 2.5 MPa) for demanding thermal applications.

- Operates efficiently in a wide temperature range (-40°C to 200°C).

Attribute of Thermally Conductive Gap Filling Paste

| Attribute | Value |

|---|---|

| Brand | Fonitaniya |

| Serial Number | FON-10115 |

| Thermal Conductivity | 1.0–2.0 W/m·K (~5.77–11.54 BTU·in/ft²·h·°F) |

| Adhesive Strength | 2.0–2.5 MPa |

| Curing | Room temperature or accelerated curing |

| Operating Temperature | -40°C to 200°C (-40°F to 392°F) |

| Applications | PCBs, power modules, automotive systems, consumer electronics |

Thermal Gap Filler

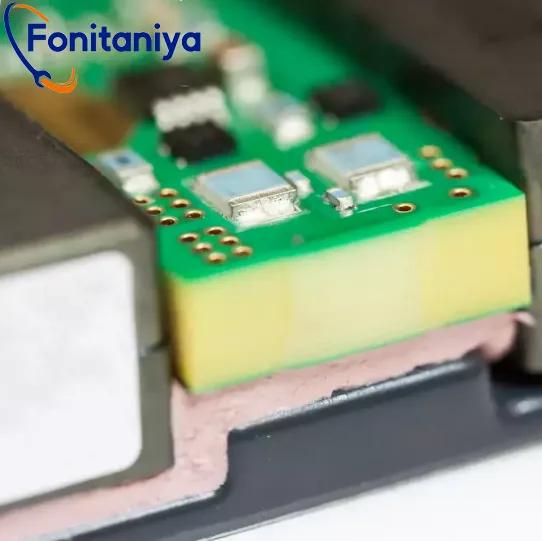

The FON-10115 Thermal Gap Filler is a high-performance, dual-component thermal interface material designed to optimize heat dissipation in electronics and industrial applications. With thermal conductivity ranging from 1.0 to 2.0 W/m·K, this gap filler ensures efficient thermal transfer while maintaining structural integrity. Its low-stress design and conformability make it ideal for filling air gaps between intricate topographies, improving overall device performance.

This thermal gap filler is suitable for a variety of applications, including printed circuit boards (PCBs), power modules, automotive systems, and consumer electronics. It can be cured at room temperature or with accelerated heating, providing flexibility for diverse manufacturing processes. The material’s excellent adhesive strength, combined with its ability to function in extreme temperatures (-40°C to 200°C), makes it a versatile and reliable solution for thermal management challenges.

Application

Ideal for filling air gaps in PCBs, power modules, and automotive systems, enhancing thermal management and reliability.

If you want to customize tapes of other specifications, you can contact us to customize the specifications you want.

When can I get my quotation?

We will provide you with a detailed quotation as soon as we receive your inquiry. Typically, we will send you a quote within 24 hours. If your requirements are complex or need custom services, it might take a bit longer, but we will keep you informed of the progress promptly.

What is your order schedule?

After confirming your order, we will schedule production based on your requirements and our production plan. Generally, the production cycle for standard orders is 2-3 weeks. If you have an urgent order, please contact us as soon as possible. We will do our best to accommodate your request and arrange expedited production.

Can I get samples?

Yes, we are happy to provide samples for you. Please contact our sales team with your specific needs and sample type, and we will arrange for the samples to be sent to you as soon as possible. Some samples may require a small fee, but in most cases, we offer free samples for testing and evaluation.

Can I print my logo on the tape?

Absolutely. We offer customization services and can print your logo on the tape according to your requirements. Please provide a high-quality logo file and specific printing requirements. Our design team will create a draft design for your approval. We will also provide samples for you to confirm before production.

What if I don't have detailed requirements?

If you are unsure about the specific requirements, our technical team is more than happy to offer professional advice. Just tell us your application scenario and basic needs, and we will recommend the most suitable tape solution based on our extensive experience and wide range of products. We can also provide sample testing to ensure our products meet your needs.