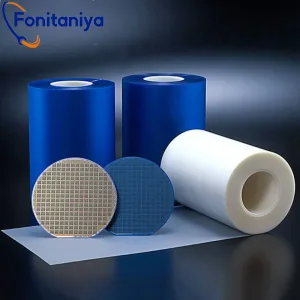

UV Curable Tape for LED Manufacturing

- UV-curable adhesive allows for clean and efficient release after exposure.

- Supports high precision in LED chip cutting and positioning processes.

- Prevents chipping or flying debris during cutting operations.

- Available in multiple thickness variants to meet diverse manufacturing needs.

Attributes of UV Release Film Tape for LEDs

| Attribute | Details |

|---|---|

| Brand | Fonitaniya |

| Serial Number | FON-10122 |

| Thickness Variants |

|

| Adhesion Strength (N/25mm) |

|

| Adhesion After UV Release |

|

| UV Release Energy | 300-500 mJ/cm² |

Polyolefin Tape for LED manufacturing

The Fonitaniya FON-10122 series UV curable tape is a high-performance protective tape designed for LED manufacturing processes, including miniLED and microLED applications. This product offers excellent adhesive stability for positioning and cutting, ensuring superior reliability during LED chip production.

With a UV-release feature, the tape enables clean removal after curing, making it ideal for high-precision operations such as LED chip separation and frame processing. The tape is available in multiple thickness options and is resistant to shearing and environmental stress, providing robust supports.

Application

Ideal for LED chip cutting, miniLED frame processing, and precision glass printing.

If you want to customize tapes of other specifications, you can contact us to customize the specifications you want.

When can I get my quotation?

We will provide you with a detailed quotation as soon as we receive your inquiry. Typically, we will send you a quote within 24 hours. If your requirements are complex or need custom services, it might take a bit longer, but we will keep you informed of the progress promptly.

What is your order schedule?

After confirming your order, we will schedule production based on your requirements and our production plan. Generally, the production cycle for standard orders is 2-3 weeks. If you have an urgent order, please contact us as soon as possible. We will do our best to accommodate your request and arrange expedited production.

Can I get samples?

Yes, we are happy to provide samples for you. Please contact our sales team with your specific needs and sample type, and we will arrange for the samples to be sent to you as soon as possible. Some samples may require a small fee, but in most cases, we offer free samples for testing and evaluation.

Can I print my logo on the tape?

Absolutely. We offer customization services and can print your logo on the tape according to your requirements. Please provide a high-quality logo file and specific printing requirements. Our design team will create a draft design for your approval. We will also provide samples for you to confirm before production.

What if I don't have detailed requirements?

If you are unsure about the specific requirements, our technical team is more than happy to offer professional advice. Just tell us your application scenario and basic needs, and we will recommend the most suitable tape solution based on our extensive experience and wide range of products. We can also provide sample testing to ensure our products meet your needs.