Understanding the Role of UV Tapes in LED Manufacturing

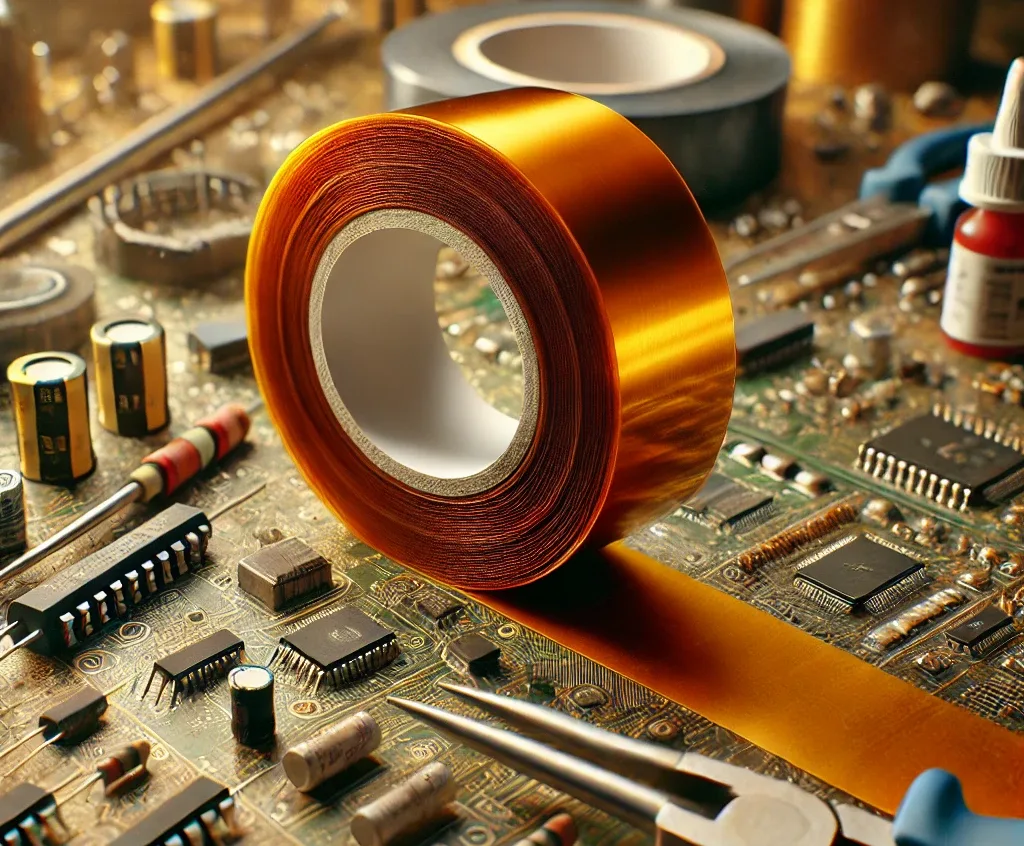

In the world of high-precision electronics, especially in the LED sector, every step in the production process needs to be flawless. One often-overlooked yet essential component is Protective UV Tape for LED Chips.

This specialized tape plays a critical role during LED chip handling, packaging, and coating. It acts as a temporary adhesive layer, protecting the chip surface from contamination and physical damage while ensuring stability during lamination or die bonding. After processing, it can be easily removed using UV light exposure, leaving no residue behind.

Key Benefits of UV Protective Tapes for LED Applications

The use of UV tapes provides several clear advantages in LED manufacturing:

- Precision Chip Protection: They safeguard delicate LED chips during movement, inspection, or coating.

- High-Temperature Resistance: Tapes like the FON-10124 series can tolerate up to 180°C, ideal for rigorous packaging stages.

- Residue-Free Removal: UV-curable adhesives allow for a clean detachment after UV exposure, reducing rework.

- Improved Process Efficiency: Streamlines chip processing with fewer contamination or alignment errors.

Introduction to Fonitaniya FON-10124 UV Release Tape

The Fonitaniya FON-10124 series represents the latest in UV release film innovation for LED chip protection. Engineered for precision and repeatability, it’s optimized for the demanding requirements of miniLED and microLED production.

This tape is built with a high-quality PET base film and a UV-curable adhesive layer that delivers excellent chip protection, thermal endurance, and release performance—all in one.

Unique Features That Set FON-10124 Apart

- Advanced UV-Curable Adhesive: Activates under UV light for controlled, residue-free removal.

- PET-Based Construction: Ensures dimensional stability during high-precision alignment.

- High Thermal Tolerance: Withstands up to 180°C, suitable for demanding chip packaging.

- Optimized Thickness Variants: Available in multiple thicknesses to fit different applications like chip insulation and LED lamp encapsulation.

Why UV Release Tapes Are Crucial for miniLED and microLED

The miniaturization of LED chips in miniLED and microLED technologies demands ultra-clean, reliable handling. Any contamination or residue can disrupt light output or cause device failure.

Protective UV tape for LED chips ensures consistent adhesion during processing but releases cleanly after UV exposure, minimizing the risk of contamination or chip damage. It also supports extremely tight process tolerances essential in fine-pitch applications.

The Manufacturing Process and Application Workflow

- Chip Placement: Chips are temporarily fixed with UV tape.

- High-Temp Processing: Coating, bonding, or encapsulation is carried out at temperatures up to 180°C.

- UV Exposure: A short UV light exposure deactivates the adhesive.

- Clean Removal: The tape is peeled away cleanly without affecting the chip.

This process reduces waste, protects chip surfaces, and enhances assembly consistency.

Technical Specifications of FON-10124 UV Tape

| Parameter | Specification |

|---|---|

| Adhesive Type | UV-curable |

| Temperature Resistance | Up to 180°C |

| Base Film | PET |

| Adhesion Stability | High |

| Residue After Peel | None |

| Available Thicknesses | Custom options |

These specs make the FON-10124 series suitable for modern, automated LED packaging environments.

Compatibility with LED Packaging Materials

The PET construction of UV release tapes ensures excellent compatibility with LED chip surfaces and encapsulants. They don’t interfere with optical materials or coating processes, making them ideal for:

- LED encapsulation

- Protective film lamination

- Wafer-level packaging

Their chemical stability also supports environmental requirements like RoHS compliance.

Comparison: UV Tape vs. Traditional Protective Films

| Feature | UV Release Tape | Traditional Film |

|---|---|---|

| Clean Removal | Yes | Often leaves residue |

| Reworkability | High | Limited |

| Temperature Tolerance | Up to 180°C | Lower |

| UV Control | Precise | Not applicable |

| Chip Alignment Support | Excellent | Average |

UV tapes are clearly better suited for advanced LED chip processes, particularly where cleanliness and precision are paramount.

Common Challenges Solved by UV Tapes

- Voiding & Misalignment: Strong, stable adhesion holds chips in place during processing.

- Residue & Contamination: UV light neutralizes adhesive properties, ensuring clean removal.

- Handling Damage: Protective film shields chips from scratches and static buildup.

Storage and Handling Best Practices

- Store at 20–25°C in a clean, dry place.

- Avoid direct sunlight or UV exposure before use.

- Use within 6–12 months for best results.

- Clean substrates before application to maintain adhesion quality.

Real-World Applications in LED Production

This UV tape is widely used in:

- miniLED display backlighting units

- microLED chip transfer and bonding

- Automotive headlamp LED packaging

- General LED encapsulation and protection

Its performance has made it a go-to solution in high-volume, precision-driven LED production lines.

FAQs about Protective UV Tapes for LED Chips

Q1: What is UV release tape?

A: It’s a protective adhesive tape that releases cleanly after UV exposure, ideal for chip handling and packaging.

Q2: Why is PET used as the base film?

A: PET offers dimensional stability, chemical resistance, and heat tolerance.

Q3: What temperatures can it withstand?

A: Up to 180°C during typical LED manufacturing processes.

Q4: Does it leave any adhesive residue?

A: No. The UV-curable adhesive is designed for clean release after exposure.

Q5: What types of LED processes use this tape?

A: Especially useful in miniLED and microLED chip bonding and coating stages.

Q6: Is the tape RoHS compliant?

A: Yes, most UV release tapes like FON-10124 meet RoHS environmental standards.

Conclusion: Advanced Protection for High-Precision LED Chips

As LED chip manufacturing moves toward miniaturization and tighter process tolerances, protective UV tape for LED chips has become an essential solution. Its high-temperature tolerance, clean removal, and precision adhesion help manufacturers reduce defects and improve yields—especially in miniLED and microLED applications.

With a strong focus on reliability and innovation, Fonitaniya is dedicated to delivering next-generation UV release tape solutions that support the future of advanced LED packaging.