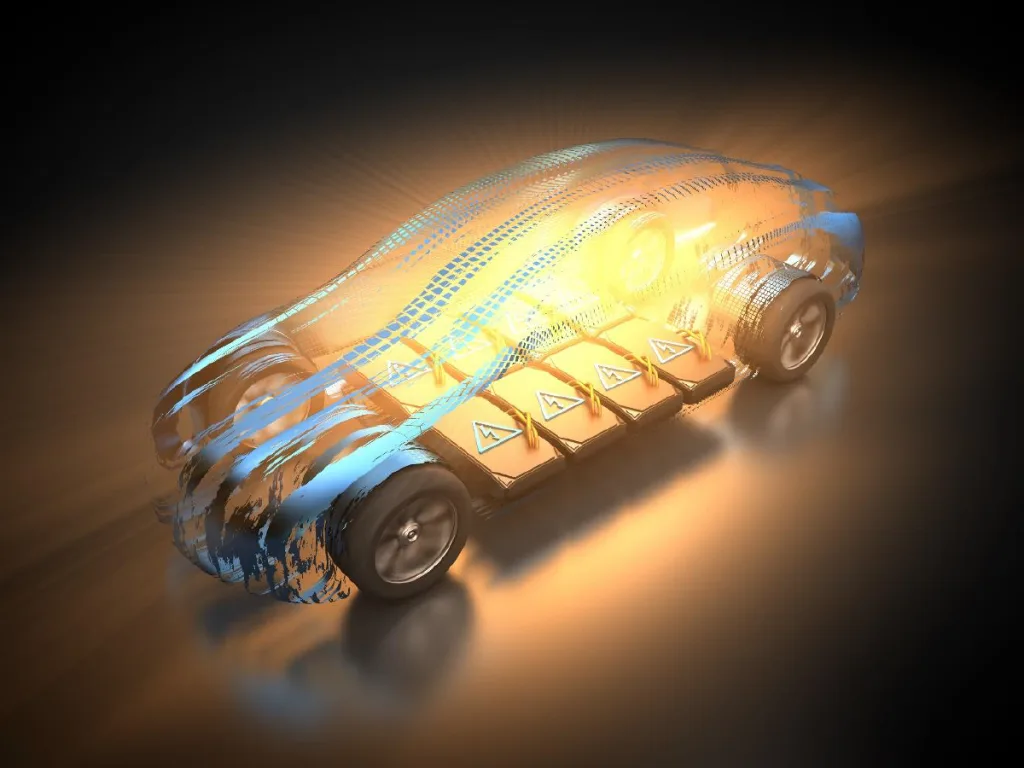

Did you know that improperly managed heat can shorten an electric vehicle (EV) battery’s lifespan by as much as 30%? As the demand for electric vehicles continues to surge, understanding and implementing effective thermal management techniques becomes crucial for manufacturers. In this article, we’ll delve into the vital role of thermal interface materials (TIMs) in enhancing the performance and safety of EV batteries, and how companies like Fonitaniya™ are leading the way in innovative solutions.

Understanding Thermal Interface Materials (TIMs)

Thermal Interface Materials are specialized substances designed to improve the thermal coupling between different components in electronic systems, particularly in electric vehicles. Their primary function is to assist in the efficient transfer of heat generated by battery cells and other components, thus ensuring optimal performance and safety during operation. In the context of EVs, excessive heat can lead to diminished battery life, reduced efficiency, and, in extreme cases, safety hazards such as thermal runaway.

The Challenge of Battery Performance and Thermal Management

As electric vehicle adoption increases, manufacturers are faced with unique thermal management challenges. Consumer demand now leans heavily toward longer ranges and enhanced reliability. As a result, it’s imperative for OEMs to find partners with a deep understanding of thermal management to help address these challenges effectively.

Increasing battery performance is one of our core objectives at Fonitaniya™, but it comes with distinct hurdles linked to thermal management. For instance, while pre-heated cells can enhance performance by increasing reaction rates, excessive heat can pose significant safety risks. This intricate balance makes effective thermal management more essential than ever.

Improved Thermal Energy Management Solutions

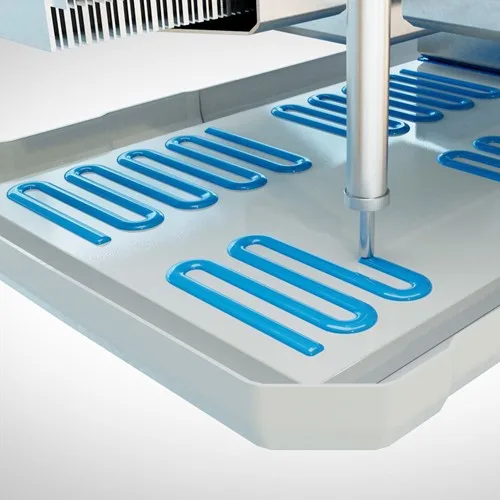

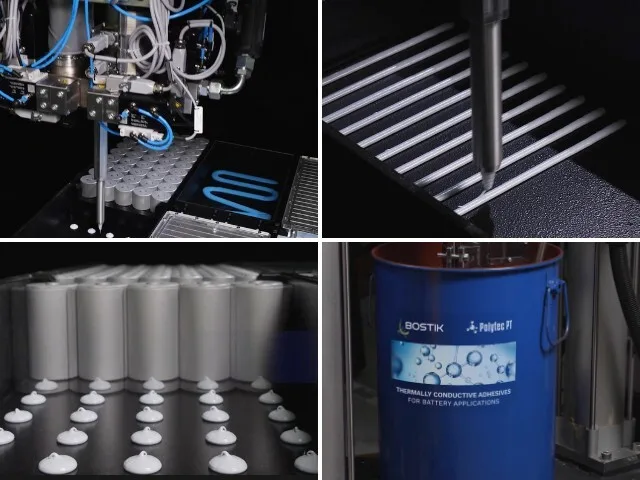

Fonitaniya™ utilizes its comprehensive knowledge of thermal management to help customers choose the right TIM solutions for effective heat transfer between cells and other critical components. By leveraging international partnerships, we can deploy leading-edge materials that better manage thermal energy.

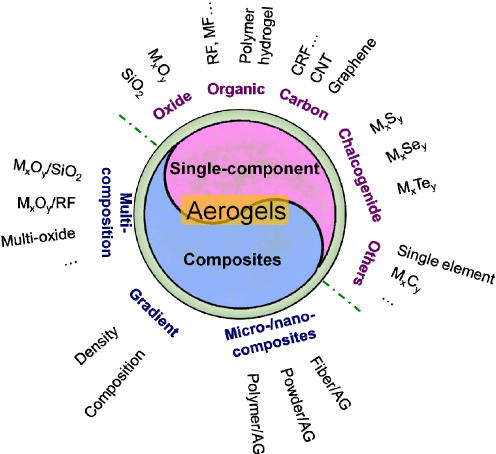

Our range of TIMs includes both solid and liquid formats, each designed with unique thermodynamic properties that enable optimal regulation of heat transfer. For instance, our liquid TIM systems often act as “gap fillers,” providing excellent electrical insulation alongside low density, which helps reduce the overall battery weight without compromising performance.

In addition, our solid TIMs, available as die-cut conductive pads, are particularly useful in various applications. These silicone-based materials feature high dielectric properties that resist breakdown, suppress arcing, and reduce electric conductivity. Notably, they also exhibit extremely low outgassing, recorded at less than 70 parts per million (PPM), making them an ideal choice for automotive applications.

Driving Safety and Longevity with Effective Thermal Management

Effective heat management is crucial for more than just performance; it directly impacts battery safety and lifespan. By maintaining optimal operational temperatures, TIMs help enhance both vehicle performance and battery durability. A study by Battery University indicates that lithium-ion batteries operating within their optimal temperature ranges can experience up to a 50% increase in lifespan.

By channeling and transferring heat away from battery cells, TIMs ensure that electric vehicles operate efficiently and safely — especially during rapid heating and cooling cycles typically observed in various driving conditions. Fonitaniya™ is dedicated to supporting OEMs in developing battery systems that harness these advantages through advanced thermal management strategies.

Related article: Advanced thermal management in EVs.

Innovations in Thermal Interface Materials

Innovation in thermal interface materials is not simply about creating new products; it involves finding ways to apply existing materials in more effective ways. This approach aligns with the industry’s need for sophisticated solutions that are scalable and cost-efficient.

At Fonitaniya™, we focus on engineering TIMs that can be implemented on a large scale, providing our clients with solutions that are not just innovative but also practical. By collaborating closely with our partners, we identify materials that can be adapted from other sectors, enabling us to develop cutting-edge thermal management solutions that push the boundaries of what is achievable.

Conclusion

As electric vehicles become increasingly popular, the role of thermal interface materials in ensuring optimal battery performance and safety cannot be overstated. Fonitaniya Adhesive Tape has been an adhesive solution provider for over 15 years, specializing in innovative thermal interface materials tailored for the automotive sector. Our commitment to delivering high-quality TIMs and unparalleled expertise in thermal management positions us as a trusted partner for OEMs navigating the complex world of electric vehicles. Together, we can drive advancements that truly enhance EV performance and safety.

FAQs

What are thermal interface materials?

Thermal interface materials enhance heat transfer between components, improving thermal management in electronic systems.

How do TIMs affect battery life?

Properly implemented TIMs can enhance battery life by maintaining optimal operating temperatures during use.

What types of thermal interface materials are available?

TIMs are available in solid and liquid forms, each serving different thermal management needs.

Are thermal interface materials essential for electric vehicles?

Yes, they are critical for managing heat in electric vehicles to ensure safety and performance.

Can thermal interface materials reduce weight in battery systems?

Yes, certain liquid TIMs are lightweight and can reduce overall battery weight without sacrificing performance.