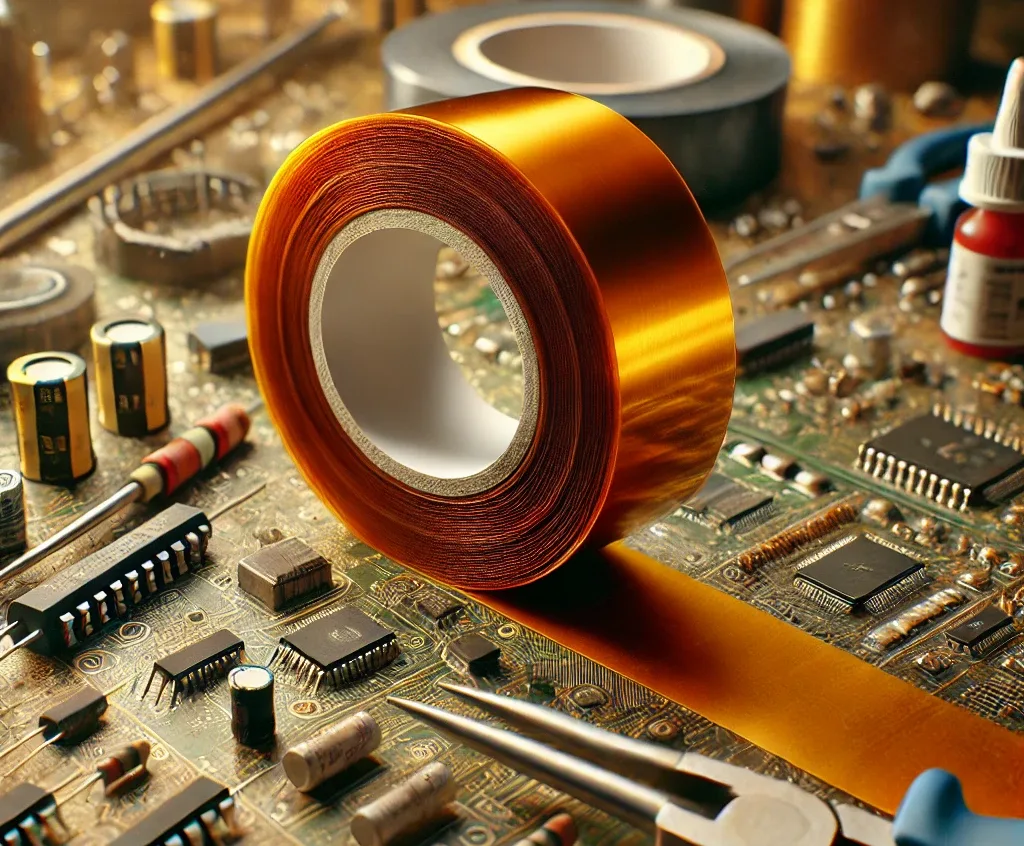

Understanding Dicing Tape and Its Functions

Dicing tape is a specialized adhesive film used to temporarily hold components—like wafers, ceramic chips, and MLCCs—during cutting, grinding, or other semiconductor processing stages. It ensures that fragile substrates remain in place and undamaged throughout the dicing cycle.

The main purpose of dicing tape is to stabilize materials and prevent shifting or chipping, making it essential for achieving high yield in microelectronic and advanced ceramic manufacturing.

What Makes Thermal Release Tape Unique?

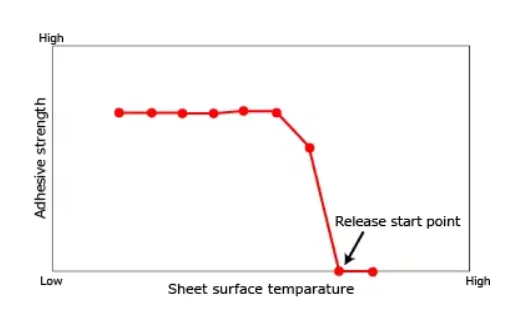

Unlike traditional dicing tapes that require mechanical force or solvents for removal, thermal release tape uses heat to reduce adhesion strength. Once the dicing or grinding process is complete, a controlled thermal exposure softens the adhesive, allowing for clean, damage-free removal.

This heat-triggered behavior makes thermal release tape ideal for fragile ceramic substrates and thin-film components, where minimal mechanical stress is critical.

Applications in Ceramic and MLCC Processing

Thermal release tape is widely used in:

- MLCC (Multilayer Ceramic Capacitor) dicing

- LTCC (Low-Temperature Co-fired Ceramics) cutting

- Advanced ceramic circuit boards

- Glass and brittle substrate processing

Its ability to maintain adhesion through complex cutting patterns and then release cleanly supports high-efficiency operations while minimizing chip loss.

What Temperature Is Dicing Tape For?

Thermal dicing tapes are generally engineered to release between 120°C and 180°C, depending on adhesive composition and substrate requirements.

| Application | Recommended Temperature |

|---|---|

| MLCC dicing | 140–160°C |

| Ceramic substrates | 150–180°C |

| Glass cutting | 120–150°C |

Choosing the correct release temperature ensures full peel without damaging the workpiece.

Thermal Release Tape for Fragile Substrates

Ceramic materials, while excellent for insulation and miniaturization, are also prone to cracking or delamination if overstressed. Thermal release tape:

- Provides firm holding power during high-speed cutting

- Releases without residue or tearing

- Minimizes substrate deformation

- Enhances yield in high-volume production lines

How Thermal Release Tape Works

- Initial Adhesion Phase: The tape is laminated to the substrate under moderate pressure.

- Processing: Dicing, grinding, or polishing takes place while the tape holds the part.

- Thermal Release Phase: The entire film is exposed to elevated temperature, which breaks down adhesion, allowing clean and safe removal.

Some versions also support UV-assisted release for hybrid process control.

Key Specifications and Performance Metrics

| Property | Specification |

|---|---|

| Adhesion Strength | High (before heating) |

| Release Temperature | 120–180°C |

| Base Material | PET |

| Residual Adhesive | None |

| Thickness Options | Multiple (customizable) |

| UV/Heat Release | Optional dual modes |

These metrics make the tape adaptable to various ceramic device geometries and processing needs.

Benefits for Ceramic Substrate Manufacturing

- Surface Integrity: No surface cracks or adhesive buildup

- Operational Efficiency: Faster release = shorter cycle times

- Yield Optimization: Fewer broken parts during detachment

- Custom Fit: Thickness customization for varied substrate types

Technical Requirements for Reliable Release

For optimal results when using thermal release tape:

- Ensure even heat distribution across the worktable

- Use consistent lamination pressure

- Match tape adhesion strength with material hardness

- Avoid thermal shock to the ceramic during tape removal

Comparison: Thermal Release Tape vs. Non-Thermal Dicing Films

| Feature | Thermal Release Tape | Non-Thermal Dicing Film |

|---|---|---|

| Release Method | Heat or UV | Manual/chemical |

| Residue Risk | Very low | Moderate to high |

| Substrate Safety | High | May cause chipping |

| Rework Potential | Excellent | Limited |

| Environmental Control | Moderate heat | Requires solvent handling |

FAQs About Ceramic Dicing Tape

Q1: Will thermal tape damage ceramic materials?

No. It is designed to protect delicate substrates and release without force.

Q2: How do I choose the right thickness?

Thinner tapes work best for dense layouts; thicker versions are ideal for larger dies.

Q3: Is UV curing required?

Some tapes offer UV + thermal dual release for flexibility, but thermal-only options are common.

Q4: What if the heat is uneven during release?

This may cause partial release. Use a calibrated thermal plate for uniform exposure.

Q5: Can the tape be used for complex cut patterns?

Yes, it supports multi-axis, irregular shapes without losing adhesion during processing.

Q6: Is this product RoHS compliant?

Yes, high-quality thermal release tapes meet RoHS and other environmental standards.

Conclusion: The Importance of Smart Adhesion in Ceramic Cutting

In high-precision industries, every micron matters. Thermal release tape provides the security, performance, and ease-of-use needed when working with sensitive materials like MLCC and LTCC substrates. Its superior adhesion during processing and clean removal afterward make it a smarter alternative to conventional dicing films.

For manufacturers seeking both precision and reliability, Fonitaniya delivers advanced thermal release tape solutions purpose-built for ceramic and fragile component dicing.