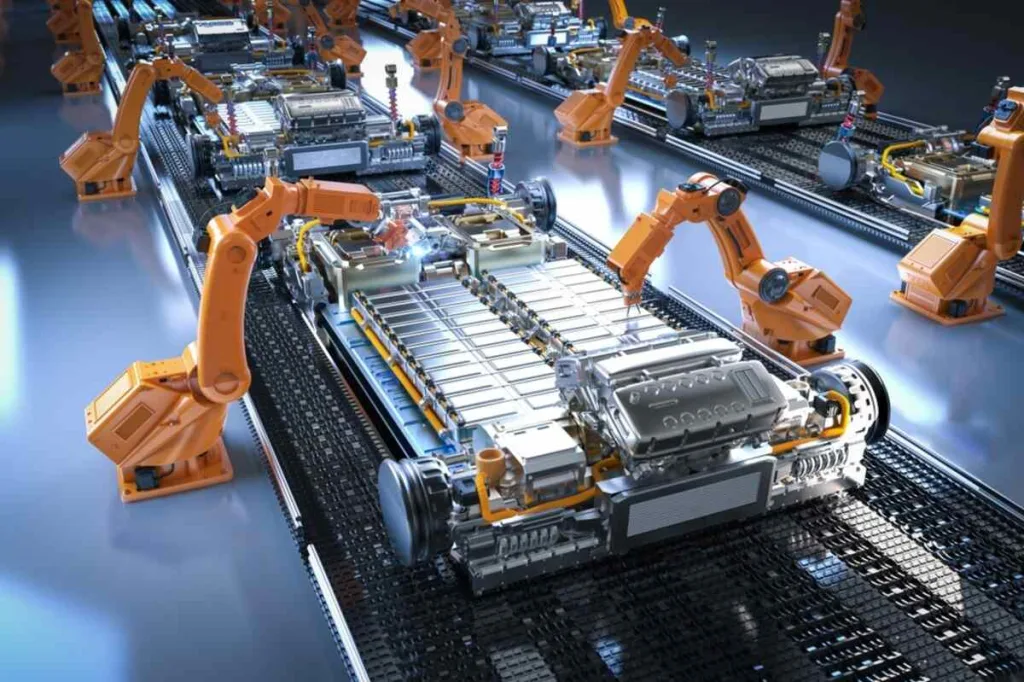

Did you know that improper heat management can reduce the lifespan of electric vehicle (EV) batteries by up to 30%? As the electric vehicle market continues its remarkable growth, with registrations rising from just 3,500 in 2013 to over 220,000 by 2019 in the UK alone, understanding thermal management technologies becomes imperative. In this article, we’ll explore how thermally conductive adhesive tape plays a crucial role in improving EV battery performance and safety, and how Fonitaniya™ is at the forefront of this innovation.

What Are Thermally Conductive Adhesive Tapes?

Thermally conductive adhesive tapes are specialized materials designed to aid in the efficient transfer of heat between electronic components, especially in battery packs. They facilitate better thermal management in electric vehicles by providing a reliable interface for heat dissipation while also securing components in place.

Fonitaniya™ has developed a range of proprietary thermally conductive foam tapes specifically engineered for superior heat dissipation in electronic architectures. By using these innovative materials, manufacturers can enhance the performance and longevity of EV batteries, which are critical components of electric vehicles.

Thermally Conductive Adhesive Tape for Battery Packs

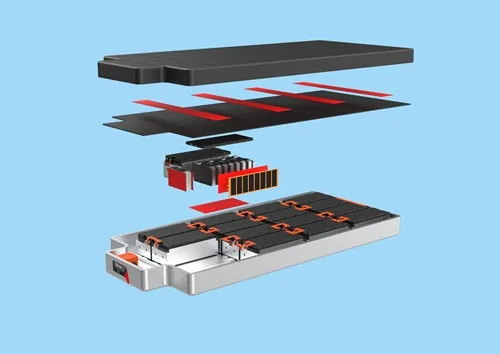

The importance of thermally conductive adhesive tape in battery packs cannot be overstated. Effective thermal management is crucial not only for enhancing battery performance but also for ensuring safety during operation. As battery technology advances, significant amounts of heat are generated, which need to be managed effectively.

For example, Fonitaniya’s thermally conductive battery pack adhesive tapes offer customizable geometries that boast a thermal conductivity rating of up to 0.6 W/(m·K). Such specifications provide reliable performance even in demanding high-temperature environments. This performance level proves essential in the increasingly competitive markets for electric and plug-in hybrid vehicles (PHEVs).

Battery Lid Thermal Protection

One prominent application of thermally conductive adhesive tape is in battery lid protection. By effectively transferring heat away from sensitive components, these tapes ensure that battery lids maintain an optimal temperature, mitigating the risks of overheating and extending overall battery life.

Battery Metal Component Insulation

Thermally conductive adhesive tapes also play a vital role in insulating metal components within the battery packs. Insulation is crucial for maintaining temperature differentials and preventing thermal runaway, a condition that can lead to catastrophic battery failures. By using high-performance adhesive tapes, manufacturers can protect battery metal components, which are often at risk of exposure to high temperatures.

Demand for Battery Pack Adhesive Tape

Battery packs for electric vehicles typically range across three performance categories: subcompact EVs with 12–18 kWh batteries, mid-sized EVs with 22–32 kWh, and premium models with batteries exceeding 60 kWh. This dynamic landscape showcases the growing importance of reliable bonding solutions like thermally conductive adhesive tape, critical for meeting the performance needs of diverse vehicle categories.

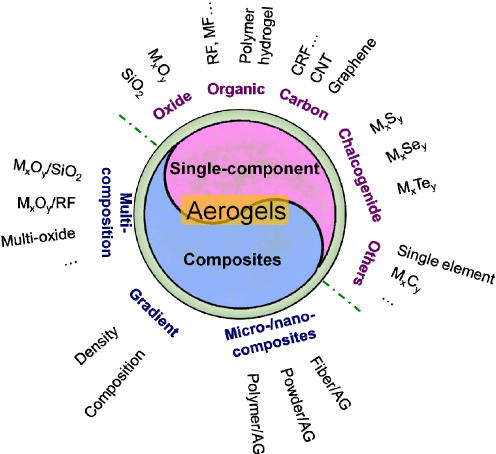

In response to this upward trajectory, Fonitaniya™ is committed to investing in thermally conductive battery pack adhesive tapes and other advanced thermal management materials. This includes options such as graphene tapes, ceramic-loaded gap-filling materials, and conductive foils, all aimed at enhancing battery performance in today’s evolving automotive technology landscape.

Mounting Various Battery Components

One significant use of thermally conductive adhesive tape is the mounting of various battery components, including frames and heating plate films. These tapes provide a lightweight solution while offering excellent thermal propagation capabilities between cells. This ensures that heat can be effectively distributed, preventing temperature hotspots that may affect battery performance or safety.

The mounting of battery modules and other parts can drive production efficiency while providing optimal thermal protection. This lightweight and conformable nature of adhesive tapes allows automotive engineers to maximize efficiency and enhance the overall integrity of the battery assembly.

Related article: Thermal interface materials for EVs.

The Importance of Thermally Conductive Adhesive Tape

As earlier mentioned, there are three crucial reasons why thermally conductive adhesive tape plays a pivotal role in electric vehicle development:

Weight Management

A mid-sized EV battery can weigh up to 230 kg, while premium batteries can reach weights of 600 kg. Comparatively, this is similar to the weight of a traditional gas-guzzler engine. Thus, securely mounting batteries requires robust adhesive solutions like thermally conductive adhesive tape, which provide essential support and weight savings.

Heat Transfer

As energy capacities in EV batteries expand, so does the associated heat production. Thermally conductive adhesive tape is essential for transferring excess heat from the battery pack to secondary heat sinks, preventing performance degradation and enhancing the service life of the battery.

Design Flexibility

As the EV market continues developing, engineers seek ways to maximize their return on investment through efficient design. Thermally conductive adhesive tape offers an adaptable solution for mounting and heat management, allowing for cleaner, more consistent bond lines and improved assembly processes compared to traditional liquid adhesives.

Conclusion

In summary, thermally conductive adhesive tape is a critical component for enhancing the performance and safety of electric vehicle battery packs. With the rapid growth of the electric vehicle market, manufacturers must prioritize effective thermal management solutions for their products. Fonitaniya Tape Companies has been at the forefront of adhesive solutions for over 15 years, specializing in thermally conductive adhesive tapes that meet the demanding needs of the automotive industry. Our commitment to quality and innovation ensures that we are a trusted partner in driving the future of electric vehicle technology.

FAQs

What is thermally conductive adhesive tape?

It is a type of tape designed to enhance heat transfer between electronic components in various applications.

How does thermally conductive adhesive tape improve battery life?

By effectively transferring heat away from batteries, it prevents overheating, thereby extending their lifespan.

Can I use thermally conductive adhesive tape in high-temperature environments?

Yes, these tapes are designed to perform reliably in high-temperature conditions.

What materials are commonly used in thermally conductive adhesive tapes?

Typically, acrylic foam and silicone materials are used for their thermal and adhesive properties.

Is thermally conductive adhesive tape easy to apply?

Yes, it offers a user-friendly application process compared to liquid adhesives and mechanical fasteners.