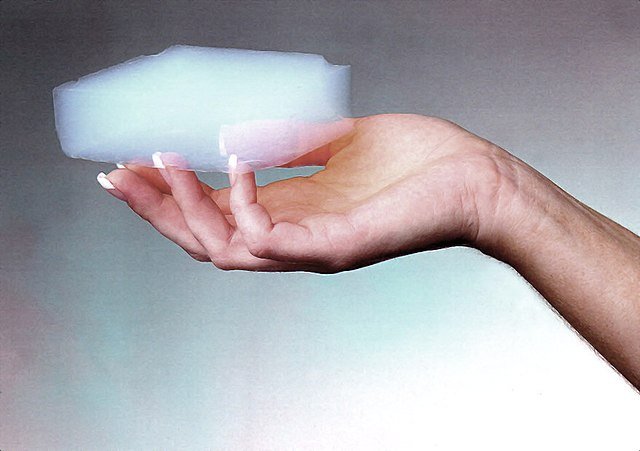

What is Aerogel?

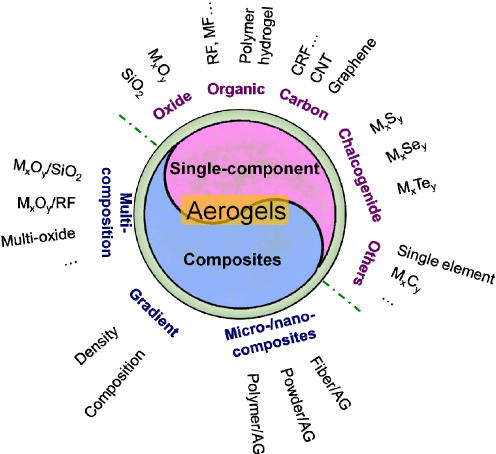

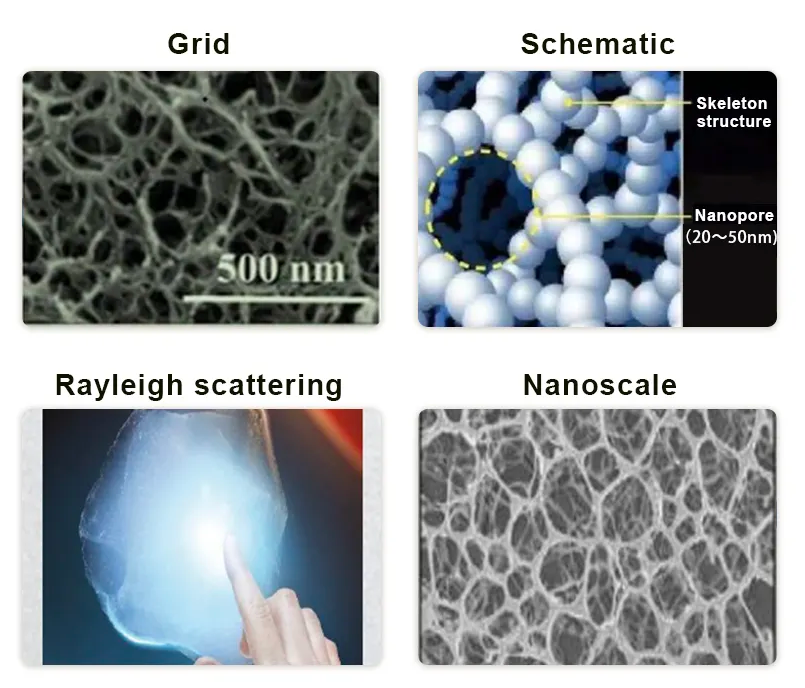

Aerogel is a remarkable material often referred to as “frozen smoke” due to its lightweight and airy structure. Primarily composed of silica, it can also include carbon or polymers. Aerogel is produced through supercritical drying, which removes liquid from a gel while retaining its internal structure. This results in a highly porous material that can contain up to 99.8% air. Variants include aerogel blankets, sheets, and films, each delivering unique properties for various applications.

The microstructure of aerogel, characterized by a network of interconnected nanoparticles, contributes to its impressive thermal insulation capabilities. With a specific surface area often exceeding 1000 m²/g, aerogels demonstrate outstanding performance in diverse industries. A study from the Heliyon journal emphasizes the utility of aerogels in insulation applications, highlighting their potential in energy-efficient technologies.

Benefits of Aerogel Blankets

Exceptional Thermal Insulation

Aerogel blankets offer exceptional thermal insulation. With a considerably low thermal conductivity, what makes these blankets particularly remarkable is their ability to withstand high temperatures, with different types exhibiting resistance capabilities ranging from 600°C to an impressive 1000°C. This high-temperature resistance makes aerogel blankets ideal for applications in industries such as aerospace, automotive, and oil and gas, where extreme heat conditions are commonplace.

Lightweight Convenience

One of the most appealing features of aerogel blankets is their lightweight nature. They weigh as little as 0.5 pounds per square foot for a 1-inch thickness, making them far easier to handle than conventional insulation materials. This lightweight quality simplifies installation processes and can result in lower shipping costs.

Space-Saving Benefits

Aerogel blankets excel in providing high R-values while occupying minimal space. With R-values exceeding 10 per inch, they allow for thinner walls without compromising performance. This is particularly beneficial in urban environments where maximizing space is crucial, enabling developers to create more efficient building designs.

Hydrophobic Properties

Aerogel blankets are inherently hydrophobic, meaning they repel water. This characteristic prevents moisture absorption and protects against mold and mildew, contributing to healthier indoor environments. Furthermore, this property preserves the insulation efficiency over time, ensuring lasting performance in challenging conditions.

High Mechanical Strength

Despite their lightweight nature, aerogel blankets possess remarkable mechanical strength. They can withstand considerable pressure without compromising their insulating properties. This feature makes them suitable for demanding applications in industries like aerospace and oil and gas, where durability is paramount.

To learn more about why aerogel blankets are a break-through in material science, please visit: aerogel sheet–material from the future.

Aerogel Blankets’ Application in Construction

In the construction industry, aerogel blankets are transforming insulation standards with their outstanding thermal properties. With a thermal conductivity as low as 0.013 W/m·K, they outperform traditional insulators, such as XPS and fiberglass, which are notably thicker. These aerogel sheets are also classified as non-combustible materials, effectively resolving the conflict between thermal insulation and fire safety. The lightweight nature of aerogel blankets, with densities below 200 kg/m³, simplifies handling and installation, reducing overall building weight. Moreover, they possess sound-absorbing qualities, enhancing acoustic comfort in buildings.

Aerogel Blankets’ Application in EVs’ Batteries

Lithium-ion batteries are prone to thermal runaway incidents, leading to potential fire hazards. By incorporating aerogel materials, manufacturers can create effective thermal barriers that prevent heat transfer between cells. Aerogel’s low thermal conductivity and A-grade fire resistance ensure that even in the event of thermal runaway, the spread of heat is mitigated, ultimately enhancing safety. One example is aerogel insulation padding coated with molded silicone/PET.

Aerogel Blankets’ Application in Oil and Gas

In high-temperature applications, such as pipelines and refining processes, these blankets can effectively withstand temperatures ranging from 200°C to 900°C. Their hydrophobic properties prevent water absorption, thereby extending the lifespan of insulating materials and reducing maintenance costs. Aerogel blankets are also lightweight and flexible, making them easy to install on various equipment, which enhances operational efficiency. Notably, global giants in the petrochemical sector are increasingly specifying aerogel materials for their thermal insulation needs.

Fonitaniya’s Aerogel Blankets are used by renouned Oil&Gas entities such as Chevron, Exxon Mobil and PetroChina. To learn more about our products, please visit aerogel blanket archive.

Aerogel Blankets’ Application in Chemistry

In chemical processing, aerogel materials are proving invaluable for insulation and minimizing energy loss. Traditional insulation options, such as mineral wool or fiberglass, often suffer from poor compressive strength and degrade over time. In contrast, aerogel blankets maintain a thermal conductivity close to that of air, approximately 0.02 W/m·K, significantly improving the thermal performance of process piping and tanks. This not only ensures that temperatures remain stable but also helps avoid the freeze-related failures that can occur in low temperatures.

Aerogel Blankets’ Application in Electric Vehicles

Aerogel blankets are increasingly incorporated to ensure the safe operation of battery packs under high heat conditions. They effectively isolate hot battery cells and minimize heat transfer, reducing the risk of thermal runaway. In supporting designs where space is at a premium, aerogel’s low density and high thermal resistance allow manufacturers to optimize battery configuration while improving safety.

Aerogel Blankets’ Application in Shipping

In shipping and marine applications, aerogel blankets address the stringent insulation requirements of vessels such as oil tankers and LNG carriers. These special ships often operate in extreme conditions, dealing with temperatures ranging from -40°C to -170°C. Aerogel’s low thermal conductivity of ≤0.02 W/m·K is ideal for minimizing thermal losses during transit, ensuring that the contents remain at the required temperatures. The unique properties of aerogel also prevent moisture ingress, protecting metal structures from corrosion.

Aerogel Blankets’ Application in Defense&Aerospace

The defense sector is increasingly recognizing the advantages of aerogel blankets due to their exceptional thermal, acoustic, and ballistic protection properties. Used in military vehicles, aircraft, and naval ships, aerogel materials help manage heat and provide insulation in high-temperature areas. Notably, NASA’s deployment of aerogels in space missions highlights their substantial insulation performance in extreme environments. Aerogel coatings also serve as effective infrared barriers, reducing the thermal signature of military equipment and enhancing stealth capabilities. Moreover, their lightweight nature contributes to improved maneuverability and operational efficiency.

Aerogel Blankets’ Application in Electronics

In the electronics industry, the demand for energy-efficient thermal management solutions is driving the adoption of aerogel materials. With their low thermal conductivity, aerogel blankets help maintain optimal operating temperatures in devices like refrigerators, electric water heaters, and consumer electronics. By incorporating aerogel insulation, manufacturers can significantly reduce the thickness of insulation layers while improving energy efficiency.

Conclusion

In conclusion, aerogel blankets represent a groundbreaking advancement in insulation technology, offering remarkable benefits across various industries. From exceptional thermal resistance to lightweight convenience, they challenge conventional insulating methods and provide innovative solutions. At Fonitaniya™, we are at the forefront of R&D for aerogel blankets, developing options tailored for diverse tasks and applications. Discover how our aerogel sheets can transform your insulation needs.

FAQs

What material is aerogel made from?

Aerogel is primarily made from silica, but variations may include carbon or polymer compounds.

How does aerogel compare to fiberglass insulation?

Aerogel offers significantly lower thermal conductivity, making it more efficient than fiberglass insulation.

Can aerogel blankets be used in extreme conditions?

Yes, aerogel blankets perform well in both extreme heat and cold, making them versatile across applications.

Are aerogel sheets environmentally friendly?

Many aerogel products are designed with sustainability in mind, contributing to energy savings.

How are aerogel blankets applied in residential buildings?

Aerogel blankets enhance thermal performance in walls and roofs, maximizing energy efficiency without excessive thickness.

Do aerogel blankets resist moisture?

Yes, aerogel blankets are hydrophobic, preventing moisture absorption and protecting against mold growth.