Did you know that without the humble PCB label, countless electronics would be impossible to assemble or repair effectively? It’s a simple piece of material, yet it plays an integral part in keeping our modern technology connected and traceable. Today, we’re taking a closer look at PCB labels—their roles, requirements, and what makes them stick (quite literally). Whether you’re an industry expert or just curious about how that sleek laptop stays functional, you’re about to learn the fascinating details of these powerful little labels.

What are PCB Labels?

PCB labels, also known as circuit board labels, are specialized labels used to provide essential information during and after the manufacturing of printed circuit boards (PCBs). These labels contain data such as serial numbers, QR codes, or barcodes that help trace and identify the board throughout its lifecycle. Imagine building a house without any blueprints—PCB labels are akin to blueprints for manufacturers and technicians, giving key insights into what’s under the surface. These labels help maintain quality control, traceability, and seamless logistics across different production stages. It’s a small but mighty solution for keeping the electronics industry on track.

What Requirements are for PCB Labels?

PCB labels must endure a lot. During the various stages of production, they face heat, chemicals, and physical wear, which means their durability is paramount. First, they need to be heat-resistant. During soldering, PCBs often reach temperatures of up to 260°C, and the label must not curl, fade, or burn. According to a study published in the Journal of Electronic Materials, “Materials used for PCB labeling must withstand temperatures over 250°C to ensure reliability during soldering, as even slight degradation could lead to data loss or unreadability of critical information”. Labels also need chemical resistance since many boards are washed with harsh solvents to remove excess flux. Additionally, PCB labels must offer excellent dielectric properties, ensuring that they don’t interfere with the circuit’s functionality.

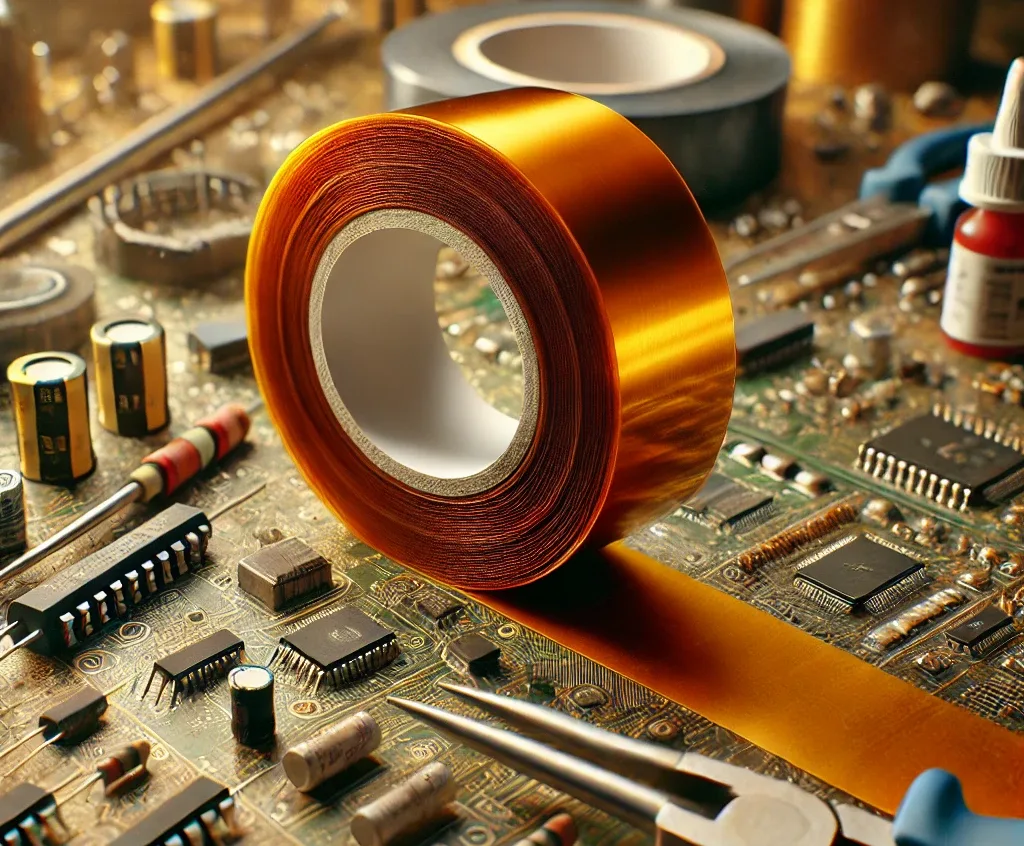

What is the Right Material for PCB Labels?

Not all labels are created equal. When it comes to PCB labels, the choice of material depends on the specific stage of the manufacturing process and the durability expectations. Below, we dive into the different scenarios and the appropriate materials.

At Start of Manufacturing Process

In the initial manufacturing stage, labels need to withstand extreme heat and direct exposure to solder. Polyimide is typically used here since it is capable of handling temperatures up to 300°C without breaking a sweat. Its resilience makes it the ideal companion for this high-stress stage.

After Board Washing, Durability Expected

Once the circuit board has gone through the washing phase, the labels are still under scrutiny. Here, polyester labels step in. They have good heat resistance, but more importantly, they resist chemical solvents used during cleaning. Polyester labels, as quoted by adhesive expert Nancy Blake, “provide the crucial resistance required to keep information intact and readable after heavy washes.”

After Board Washing, Durability Not Expected

For boards where the label will not need to remain on permanently—perhaps used only for internal tracking—economical options like paper labels or basic vinyl could suffice. In this case, the labels are designed for temporary use, and cost-efficiency is often prioritized over high durability.

Conclusion

PCB labels might seem like an afterthought, but their importance cannot be overstated. From ensuring traceability to withstanding the rigors of soldering and washing, these labels are essential in bringing electronic devices to life. At Fonitaniya Adhesive Tape Company, with over 15 years of experience in adhesive label solutions, we understand these complexities and proudly manufacture high-quality PCB and circuit board labels that meet industry needs at every stage.

FAQs

What material is best for PCB labels?

Polyimide is best for high-temperature environments, while polyester works well post-wash for chemical resistance.

How are PCB labels used in manufacturing?

They help identify, trace, and track printed circuit boards throughout various production stages.

Why do PCB labels need heat resistance?

PCB labels must endure high temperatures during soldering, which can reach up to 260°C.

Can I use regular paper labels for PCBs?

Paper labels can be used, but only for temporary purposes where durability is not required.

What is the purpose of circuit board labels?

Circuit board labels provide crucial information like serial numbers, ensuring traceability and quality control during production.