In this article, we discuss the unique composition and manufacturing process behind these blankets, their remarkable properties, and their broad applications in industries like automotive and aerospace. With a focus on performance under high temperatures, these insulation blankets are paving the way for safer and more efficient thermal management solutions.

What is Aerogel Insulation Blanket?

What is Aerogel?

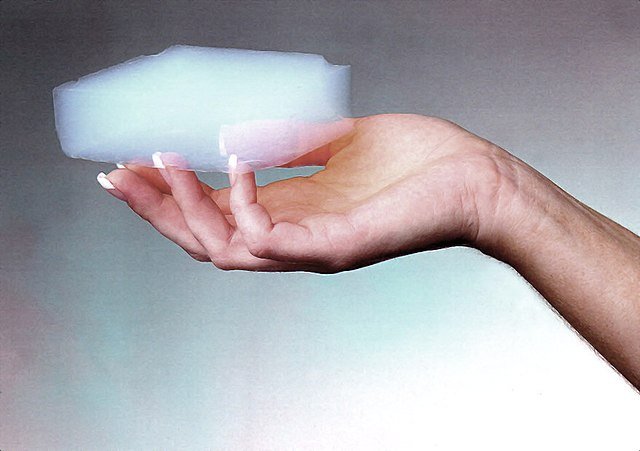

Aerogel is an extraordinary lightweight material formed by transforming a gel into a solid state while replacing the liquid component with gas. This process creates a highly porous structure, which makes aerogels incredibly low in density. Aerogel sheets, blankets, and films are all derivatives of this remarkable material, renowned for their thermal insulation capabilities.

What is the Chemical Composition of Aerogel?

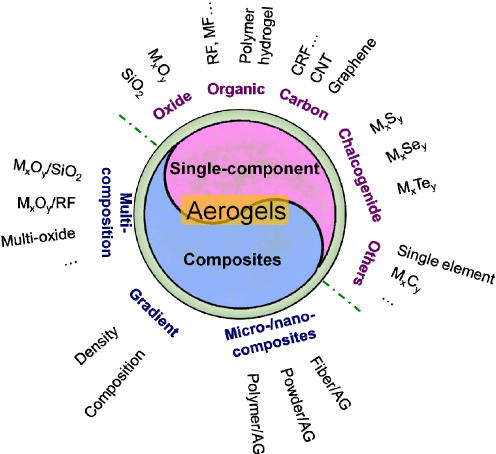

Most aerogels, particularly silica aerogels, chiefly consist of silicon dioxide (SiO2). They can also be made from alumina (Al2O3) or various organic polymers. The unique blend of these constituents provides aerogels with their outstanding properties, such as extremely low thermal conductivity.

The Properties of Aerogel and Its Microstructure

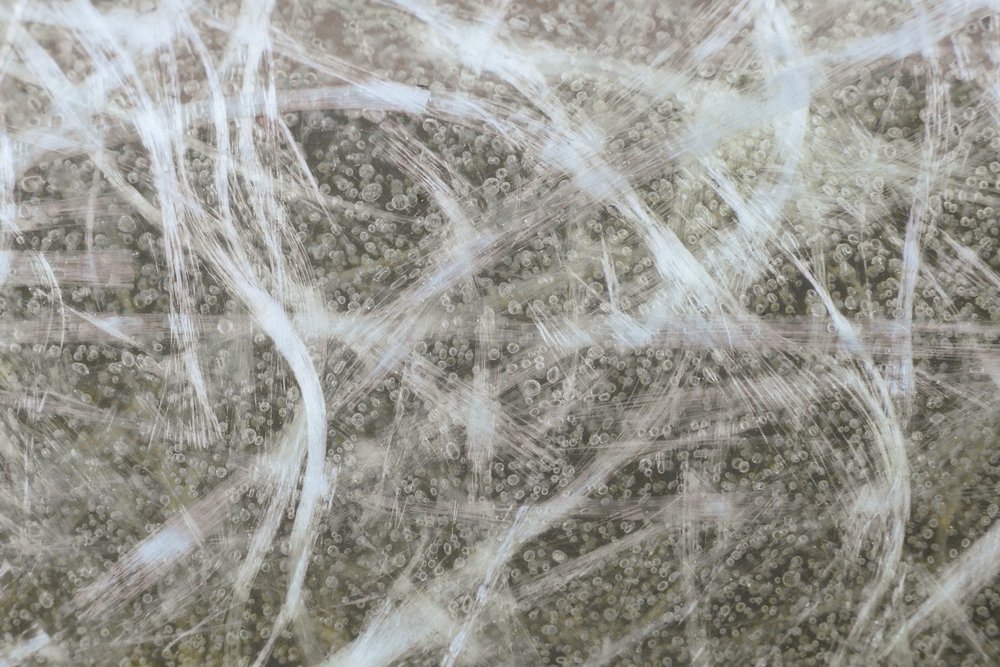

Aerogels are known for their impressive properties. Their thermal conductivity can be as low as 0.017 W/m·K, making them some of the most efficient insulators available. The microstructure of aerogels resembles a network of interconnected pores that trap air effectively, allowing them to provide superior thermal insulation while remaining incredibly light, with densities often around 1 kg/m³.

To learn more about different aerogel blanket suit for various tasks, please visit: Aerogel Blanket/ Aerogel Sheet.

What is Fibreglass?

Fiberglass is a material made from fine glass fibers. It’s known for its strength and insulating properties, commonly used in building materials and thermal insulation.

What is the Chemical Composition of Fibreglass?

Fiberglass is primarily composed of silica (SiO2), along with other compounds such as alumina, lime, and boron oxide, depending on its specific type. This combination results in a durable material that offers excellent insulation properties.

What are the Properties of Fibreglass?

Fiberglass is celebrated for its heat resistance and tensile strength. Its thermal conductivity ranges from 0.035 to 0.045 W/m·K, depending on the specific type and application. Fiberglass also demonstrates flexibility, making it easy to mold into various shapes for different uses.

To see an example of Fibreglass Aerogel Insulation Blanket, visit the link.

What is Fibreglass Aerogel Insulation Blanket?

How to Combine Aerogel with Fiberglass (The Manufacturing Process)?

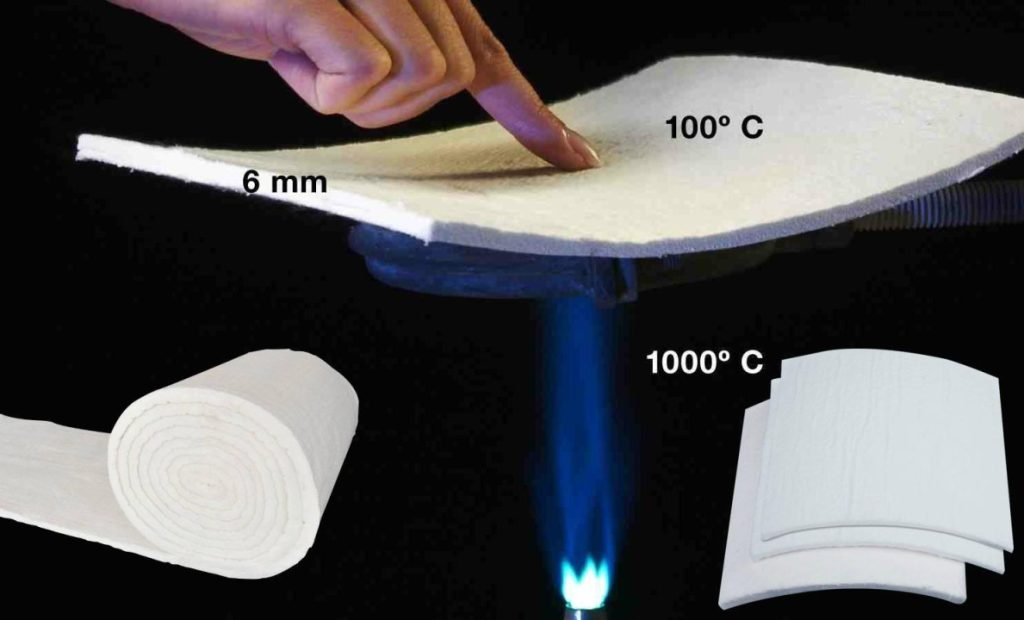

Fiberglass aerogel insulation blankets merge the advantages of both materials. The manufacturing process involves combining approximately 70% fiberglass with 30% aerogel. According to a study on Applied Materials Today, interfacial bonding of the fibreglass and aerogel can boost property of both materials. Advanced fiber reinforcement technology integrates the strength of glass fiber needle-punched felt with the lightweight, nano-porous properties of aerogel. This combination creates an efficient thermal insulator suitable for high-temperature environments.

The Attributes of Fibreglass Aerogel Blanket

Fiberglass aerogel insulation blankets possess several remarkable attributes when compared with standard fiberglass and aerogel sheets. The following chart illustrates these properties:

| Property | Fiberglass | Aerogel | Fibreglass Aerogel Blanket |

|---|---|---|---|

| Maximum Temperature Resistance (°C) | 550 | 650 | 600 |

| Density (kg/m³) | 500 | 1 ≤ 300 | 200 ± 20 |

| Thermal Conductivity (W/m·K) | 0.035 (25°C) | ≤0.017 | ≤0.020 |

| Combustion Class | A2 | A1 | A1 |

| Hydrophobicity Rate | <90% | N/A | ≥98% |

| Tensile Strength (KPa) | 350 | 400 | 800 |

This table highlights the enhanced characteristics of fiberglass aerogel blankets, particularly in terms of insulation effectiveness and structural integrity.

To learn about other types of aerogel blanket and their comparisons, please visit: What are the common types of aerogel blanket.

What is Fibreglass Aerogel Insulation Blanket Used For?

Fiberglass aerogel insulation blankets find extensive applications in industries that require advanced thermal management. They are used for insulation in electronic vehicles, battery insulation, and fire protection for marine vessels. Additionally, these blankets are effective in thermal management for chemical storage tanks and high-temperature pipeline equipment. Major companies like ExxonMobil and Shell have recognized the value of fiberglass aerogel insulation for its superior performance and compliance with environmental standards.

Conclusion

In conclusion, fiberglass aerogel insulation blankets represent a significant advancement in thermal insulation technology, blending the properties of fiberglass and aerogels. Fonitaniya™ is dedicated to R&D in aerogel blankets, including our specialized fiberglass aerogel insulation products, to meet the evolving needs of high-performance applications.

FAQs

What is a fiberglass aerogel insulation blanket?

This product combines fiberglass with aerogel for superior thermal insulation performance.

How does fiberglass compare to aerogel?

Fiberglass is more traditional, whereas aerogel offers lower thermal conductivity.

What industries use fiberglass aerogel blankets?

These blankets are widely used in automotive, aerospace, and chemical processing industries.

Can fiberglass aerogel blankets withstand fire?

Yes, they are classified as A1 for excellent fire resistance.

How effective is the insulation of fiberglass aerogel?

It has thermal conductivities as low as 0.020 W/m·K at room temperature.

Is fiberglass aerogel waterproof?

Yes, they have a hydrophobicity rate of over 98%, ensuring moisture resistance.