Kapton tape is a high-performance adhesive solution renowned for its versatility across various industries. This article explores the diverse applications of Kapton tape, highlighting its critical role in electronic circuit board manufacturing, aerospace, automotive, and many more sectors. Whether you’re an engineer, manufacturer, or procurement professional, understanding the capabilities of Kapton tape can significantly enhance your operations and product quality.

- What is Kapton Tape?

- Is Kapton Tape Conductive?

- Kapton Tape In Electronic Circuit Board Manufacturing

- Kapton Tape In SMT Temperature Protection

- Kapton Tape In Motor and Transformer Manufacturing

- Kapton Tape In Aerospace and Automotive

- Kapton Tape In the Power and Energy Industry

- Kapton Tape In Chemical and Pharmaceutical

- Conclusion

- FAQs

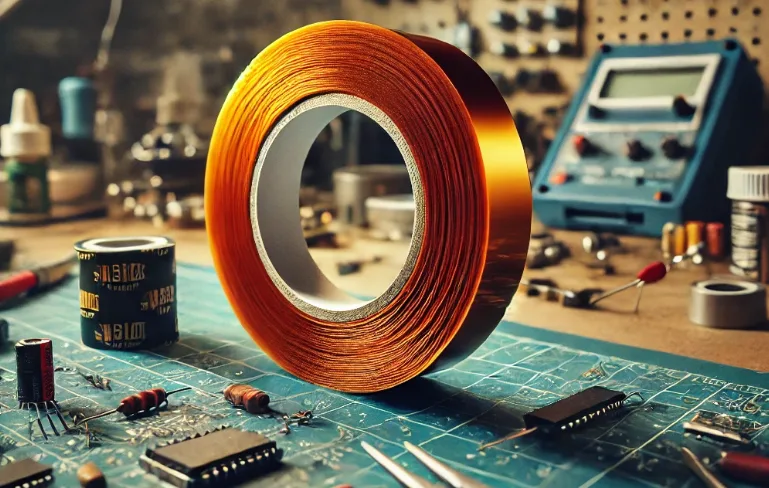

What is Kapton Tape?

What is Kapton Tape Made Of?

Kapton tape is a polyimide tape initially developed by DuPont in the 1960s. Its creation was driven by the need for reliable materials that could withstand extreme conditions, particularly in aerospace applications. The tape is composed of a thin film of polyimide, coated with a silicone adhesive, giving it remarkable thermal stability and adhesion properties. Kapton tape can endure temperatures from -269°C to 400°C (-452°F to 752°F), with black Kapton tape can endure 300°C (572°F), making it one of the most effective options for high-temperature applications.

What Are the Properties of Kapton Tape?

Kapton tape boasts a unique blend of properties that sets it apart from other adhesive solutions. It is chemically resistant, dielectric, and maintains mechanical integrity at various temperatures. According to ASTM D-2671, Kapton tape exhibits a dielectric strength of over 6,000 volts, making it ideal for electrical insulation. Its ability to resist UV light and thermal degradation ensures durability, which is crucial in high-performance applications.

To learn more about the variantion of Kapton tape, please visit: 6 key points about Kapton tape.

Is Kapton Tape Conductive?

Kapton tape is not conductive; it is an excellent insulator. This property is vital in preventing electrical and thermal transfer, especially in sensitive electronic applications. As a non-conductive material, Kapton tape helps protect circuits and components from unintended electrical interference, ensuring optimal performance. To prevent electrostatic discharge, some Kapton tape is coated with antistatic adhesive; they are called antistatic Kapton tape.

Kapton Tape In Electronic Circuit Board Manufacturing

Kapton tape serves a fundamental role in electronic circuit board (PCB) manufacturing. It provides insulation during soldering processes, protecting delicate components from heat damage. By using Kapton tape, manufacturers can ensure that the integrity of sensitive parts remains intact, resulting in a more reliable PCB. According to a study from IPC, around 60% of PCB manufacturers utilize high-temperature tape like Kapton during production for optimal results.

Kapton Tape In SMT Temperature Protection

In surface mount technology (SMT), Kapton tape is instrumental in temperature protection. During the soldering process, it protects adjacent components from excessive heat, thus preventing damage and ensuring reliability. The ability of Kapton tape to withstand extreme temperatures is vital for maintaining the quality of the solder joint, which is crucial for the longevity of electronic devices.

Kapton Tape In Motor and Transformer Manufacturing

In the motor and transformer manufacturing industries, Kapton tape provides reliable electrical insulation for windings, preventing failures due to thermal overload. Its resistance to transformer oils and other chemicals makes it invaluable for maintaining operational efficiency in systems exposed to high temperatures.

Kapton Tape In Aerospace and Automotive

Aerospace and automotive industries frequently rely on Kapton tape due to its exceptional thermal resistance and lightweight properties. Engineers use Kapton tape for insulation in wiring and components exposed to extreme temperatures. Its durability ensures safety and reliability in critical systems, contributing to performance in both sectors. According to the Aerospace Industries Association, over 75% of aerospace engineers prefer Kapton-based solutions for high-performance applications.

Kapton Tape In the Power and Energy Industry

The power and energy industry benefits from using Kapton tape in applications requiring high insulation and heat resistance. It is commonly used in transformers, capacitors, and other electrical equipment, ensuring operational safety and preventing mishaps. Kapton’s unique properties allow it to remain functional under variable conditions, which is essential for maintaining energy transmission efficiencies.

Kapton Tape In Chemical and Pharmaceutical

In the chemical and pharmaceutical sectors, Kapton tape’s chemical resistance makes it an ideal choice for sealing and insulation applications. It assists in maintaining the integrity of sensitive equipment exposed to harsh chemicals and conditions. Additionally, its non-toxic nature aligns with industry standards for safety and compliance.

Conclusion

Kapton tape is an unrivaled adhesive solution due to its unique properties and diverse applications across several industries. From electronic circuit board manufacturing to pharmaceutical applications, its ability to withstand extreme conditions ensures reliability and performance. As you consider high-performance adhesive solutions, remember that Fonitaniya™ is a leading Kapton tape manufacturer and electronic adhesive tape supplier devoted to fulfilling your unique business needs.

FAQs

Can Kapton tape be used outdoors?

Kapton tape can be used outdoors but should be checked for exposure to prolonged UV light.

How do I remove Kapton tape?

Gently peel it back, ensuring the underlying surface is not damaged.

Is Kapton tape reusable?

Kapton tape is typically designed for single use, as reapplication may compromise adhesion properties.

What are common sizes for Kapton tape?

Kapton tape is available in various widths, typically ranging from 1/4 inch to several inches.