This article explores the revolutionary pre-oxidized fibre aerogel blanket, highlighting its unique composition, manufacturing process, and exceptional thermal properties. We delve into the fascinating world of aerogel sheets and pre-oxidized fibres, comparing their attributes and applications in various industries, including new energy vehicles and electronics. With a focus on performance under demanding conditions, this advanced insulation material demonstrates the perfect blend of lightweight design and superior thermal efficiency, making it indispensable in modern engineering solutions.

What is Aerogel Sheet?

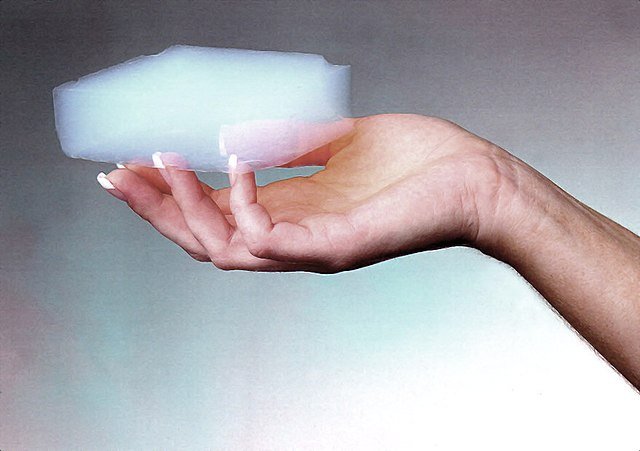

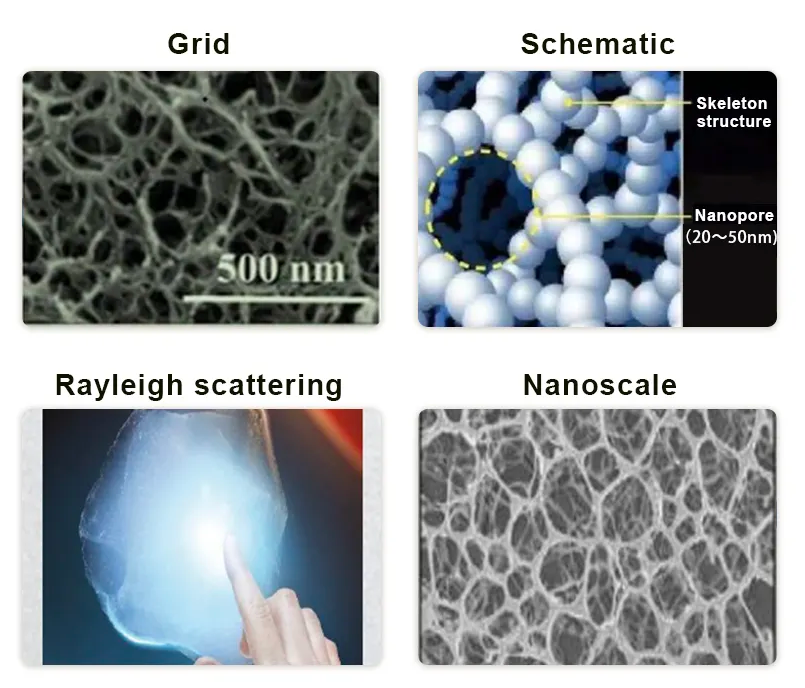

Aerogel is a truly fascinating material that has gained attention for its extraordinary insulation properties. Often called “frozen smoke,” aerogels are formed through a process that replaces the liquid in a gel with gas, resulting in a solid structure comprised mostly of air. Aerogel sheets, blankets, and films are popular forms of this material, each designed to meet specific thermal management needs in a variety of applications.

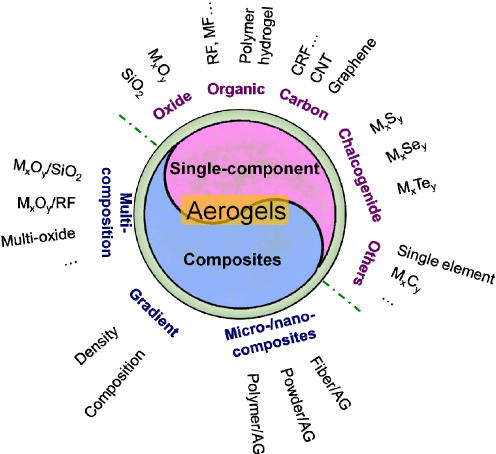

The chemical composition of aerogel generally consists of silica, though it may also include alumina and various polymers, depending on the desired properties. The microstructure of aerogels is characterized by their nanoporous nature, with pores as small as 20 nanometers. This unique structure allows aerogels to achieve extremely low thermal conductivities ranging from 0.017 to 0.035 W/m·K. With a density often as low as 1 kg/m³, aerogels stand as some of the lightest materials known, making them highly effective for insulation in diverse environments.

To learn more about different aerogel blanket suit for various tasks, please visit: Aerogel Blanket/ Aerogel Sheet.

What is Pre-Oxidized Fibre?

Pre-oxidized fibre is an advanced thermal material produced from polyacrylonitrile (PAN) which undergoes an initial oxidation phase. This process enhances its thermal stability and makes it suitable for high-temperature applications.

What is the Chemical Composition of Pre-Oxidized Fibre?

Pre-oxidized fibre typically consists of carbon and nitrogen. The unique chemical structure allows it to withstand temperatures without degrading, providing excellent insulation in high-stress applications.

What is the Difference Between Pre-Oxidized Fibre and Carbon Fibre?

While both materials have high-temperature resistance, pre-oxidized fibre is engineered for superior thermal stability compared to standard carbon fibre. This makes it an ideal candidate for applications requiring consistent performance at elevated temperatures.

What are the Structural Properties of Pre-Oxidized Fibre?

Pre-oxidized fibres feature a robust structure characterized by high tensile strength and excellent flexibility, properties that make them suitable for high-performance insulation applications. Their unique microstructure allows them to withstand mechanical stress without compromising durability.

How Does Pre-Oxidized Fibre Perform Under Heat?

Pre-oxidized fibre can typically handle temperatures of up to 350°C, making it a reliable choice for industries like new energy vehicles and electronic products, where thermal management is critical.

What is Pre-Oxidized Fibre Aerogel Blanket?

How to Combine Aerogel with Pre-Oxidized Fibre (The Manufacturing Process)?

The creation of pre-oxidized fibre aerogel blankets integrates the strengths of both materials for maximum thermal efficiency. The process involves layering pre-oxidized fibre with aerogel to enhance insulation performance. By combining approximately 70% pre-oxidized fibre with 30% aerogel, manufacturers create a lightweight yet durable blanket designed to perform under high temperatures.

The Attributes of Pre-Oxidized Fibre Aerogel Blanket

The pre-oxidized fibre aerogel blanket exhibits unique characteristics when compared to its individual components. Here’s a quick comparison:

| Property | Pre-Oxidized Fibre | Aerogel | Pre-Oxidized Fibre Aerogel Blanket |

|---|---|---|---|

| Maximum Temperature Resistance (°C) | 350 | 650 | 350 |

| Density (kg/m³) | 200 | 1 ≤ 300 | 180 ± 20 |

| Thermal Conductivity (W/m·K) | 0.040 | ≤0.017 | ≤0.035 |

| Tensile Strength (KPa) | 600 | 400 | 800 |

| Flexibility | High | N/A | High |

| Hydrophobicity | Moderate | N/A | High |

This table showcases how the pre-oxidized fibre aerogel blanket achieves a balance between thermal protection and mechanical strength, making it ideal in demanding environments.

To learn about other types of aerogel blanket and their comparisons, please visit: What are the common types of aerogel blanket.

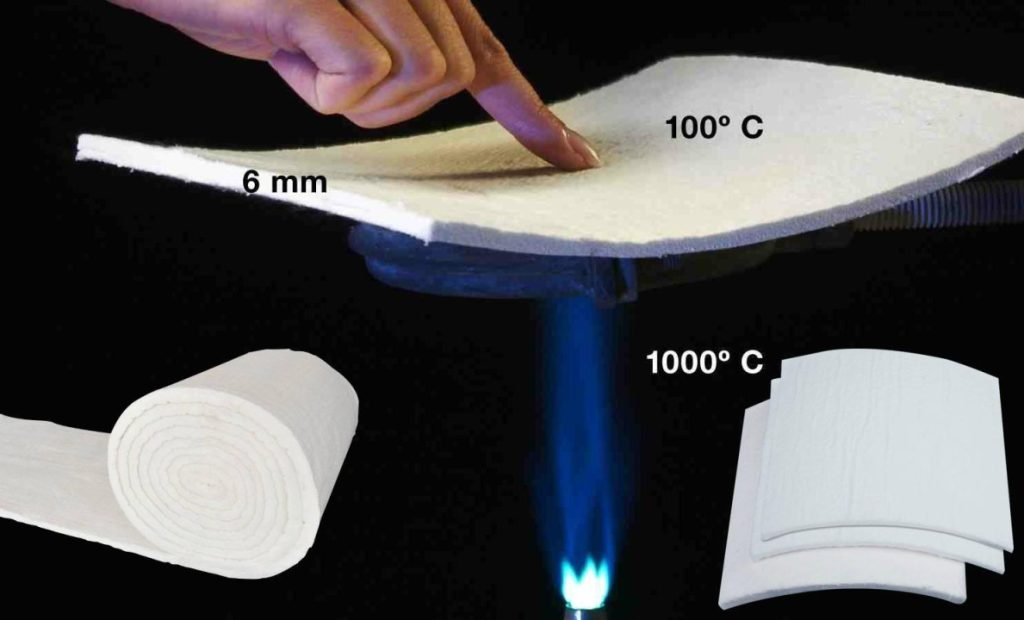

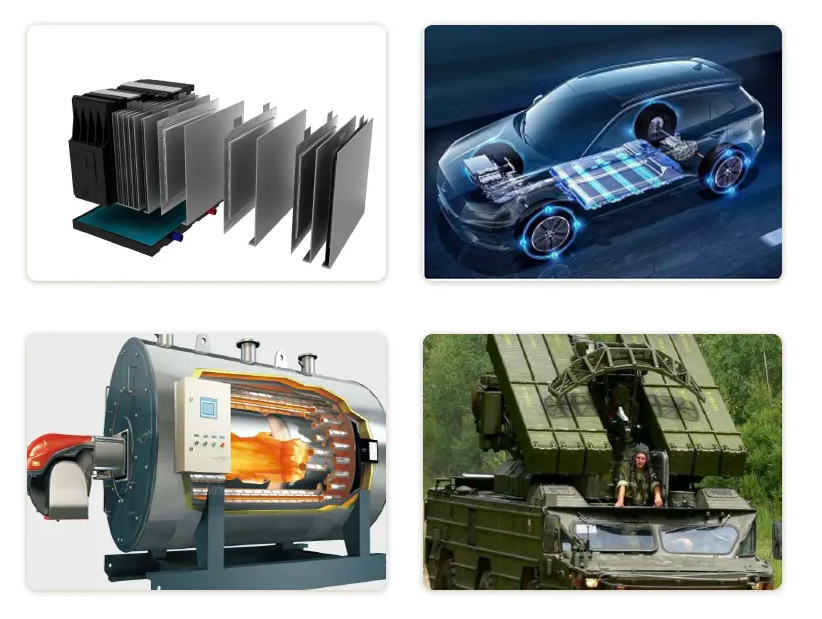

What is Pre-Oxidized Fibre Aerogel Blanket Used For?

The pre-oxidized fibre aerogel blanket finds substantial use in advanced applications where thermal management is crucial. It plays an essential role in new energy vehicles, offering vital insulation for battery modules. Additionally, it protects consumer electronic products against heat, ensuring operational reliability and safety. Its customizable thickness—ranging from 0.5 mm to 6 mm—makes it adaptable for various applications in the transportation and chemical storage industries. The insulation blanket is also useful for high-temperature pipeline equipment and cold storage systems, ensuring energy efficiency and safety in diverse sectors.

Conclusion

In conclusion, pre-oxidized fibre aerogel blankets represent a significant advancement in thermal protection technology. By merging the benefits of pre-oxidized fibre and aerogel, they meet the stringent demands of modern engineering applications. At Fonitaniya™, we prioritize R&D and offer an exceptional range of aerogel blankets, including pre-oxidized fibre products designed to address the evolving needs of the market.

FAQs

What is a pre-oxidized fibre aerogel blanket?

It combines pre-oxidized fibre with aerogel for top-tier insulation and thermal protection.

How does pre-oxidized fibre differ from carbon fibre?

Pre-oxidized fibre focuses more on thermal stability in high-temperature applications compared to conventional carbon fibre.

What are the primary uses of pre-oxidized fibre aerogel blankets?

They serve in new energy vehicles, consumer electronic products, and industrial thermal management.

Can pre-oxidized fibre aerogel handle extreme temperatures?

Yes, it withstands temperatures up to 350°C effectively.

What is the thermal conductivity of pre-oxidized fibre aerogel blankets?

Its thermal conductivity ranges up to 0.035 W/m·K.