Understanding Polycarbonate Film Tapes

Polycarbonate film tape is a high-performance insulation solution used primarily in electronics, industrial automation, and power systems. Unlike traditional tapes, polycarbonate tapes offer superior mechanical strength, flame resistance, and heat stability, making them ideal for applications that demand both safety and durability.

Among these, flame-retardant films like FR 700 stand out for their UL94 V-0 rating and suitability for EMI/RFI shielding when laminated with conductive foil.

What Is a Polycarbonate Film?

Polycarbonate film is a thermoplastic sheet produced by extruding polycarbonate resin. Known for its high impact resistance and thermal stability, it serves as the foundation for film tapes that require structural integrity and insulation in extreme environments.

Key characteristics:

- High tensile strength

- Dimensional stability under heat

- Optical clarity or light diffusion (depending on finish)

- Excellent dielectric properties

What Is a Film Tape?

Film tape is a pressure-sensitive adhesive tape backed by thin films made from materials like polycarbonate, polyester (PET), or polyimide. These tapes are used for:

- Electrical insulation

- Masking during soldering or coating

- EMI shielding

- Heat-resistant protective layering

Polycarbonate-based film tapes outperform many others due to their enhanced thermal and structural properties.

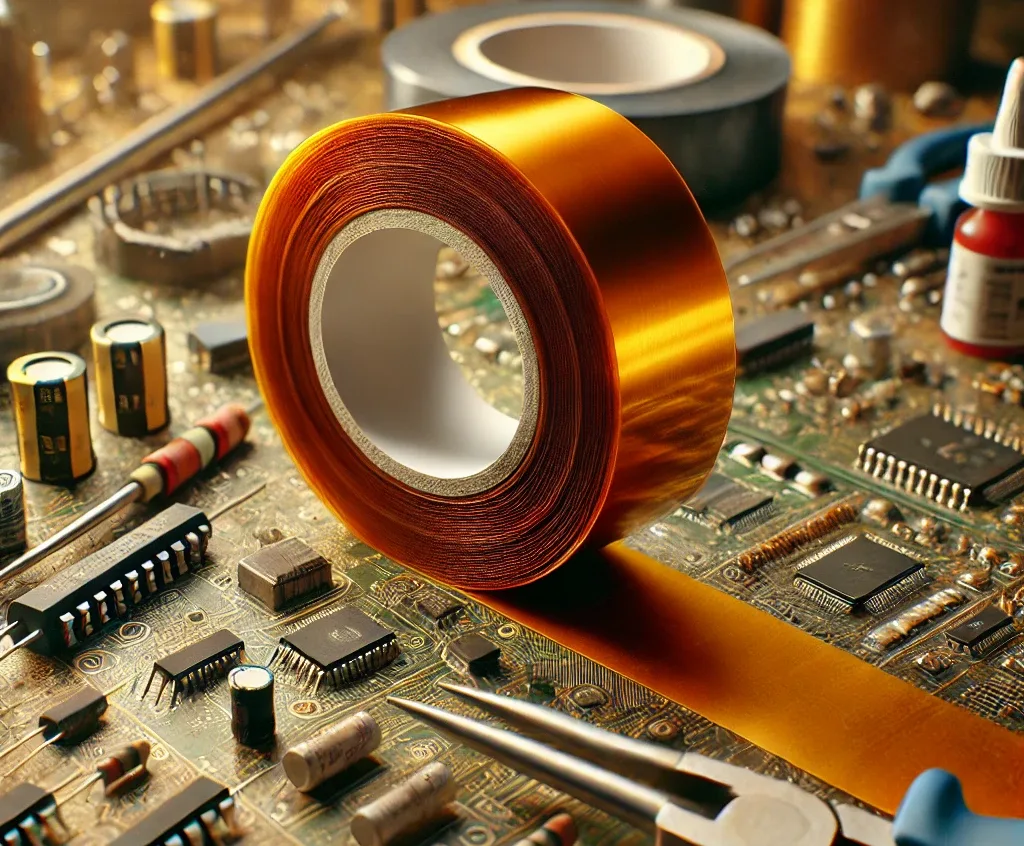

Primary Uses of Polycarbonate Film Tape

- Electrical Insulation

Polycarbonate film tape is widely used to insulate transformers, motors, PCBs, and power modules. Its flame-retardant properties and resistance to high temperatures make it especially suitable for critical electrical applications.

- EMI/RFI Shielding

When laminated with metal foil, FR-grade polycarbonate tapes offer reliable electromagnetic shielding for sensitive circuits, preventing signal interference in communication and computing systems.

- Power Supply and Battery Pack Protection

Polycarbonate tapes provide thermal stability and puncture resistance, making them ideal for insulating battery packs, especially in high-density or compact designs.

- Office & Business Equipment

Used to insulate and protect electrical panels in printers, copiers, and commercial-grade machinery, the dual-surface finish enhances both function and appearance.

Key Features of FR 700 Polycarbonate Film Tape

| Feature | Performance Summary |

|---|---|

| Flame Resistance | UL94 V-0 rating ensures minimal flame propagation |

| Surface Design | Fine matte on one side, velvet on the other – aesthetic and functional |

| Heat Stability | Maintains structure under high temperatures; ideal for formed or bent insulation shapes |

| EMI/RFI Shielding Compatibility | Excellent when laminated with metal foil |

| Mechanical Strength | Durable against tearing, puncture, and abrasion |

How to Use FR 700 Polycarbonate Film Tape

Proper handling ensures full performance. Here’s the recommended procedure:

1.Surface Preparation

Clean the substrate surface—free of oil, dust, or moisture—for best adhesion and insulation quality.

2.Cutting & Shaping

Use precision tools such as laser or die cutters. Avoid excessive force to prevent micro-cracks or distortion.

3.Forming

Heat-form gently if shaping is needed. Maintain consistent temperature to prevent warping.

4.Lamination

For EMI applications, bond with metal foil using compatible adhesives and uniform pressure.

5.Installation

Apply to the insulation zone, press evenly, and secure using mechanical fasteners or thermally stable adhesives.

Care & Storage Tips

| Precaution | Advice |

|---|---|

| Heat Sensitivity | Avoid exceeding the rated temperature to prevent material deformation |

| Chemical Exposure | Test before exposing to aggressive solvents |

| Electrical Grounding | Ensure proper earthing for electrical insulation uses |

| Storage Conditions | Store in a cool, dry, UV-free area to preserve quality |

How to Remove Film from Polycarbonate

Removing protective or insulation film from polycarbonate surfaces should be done with care:

- Use low heat (below 70°C) to soften the adhesive without damaging the polycarbonate

- Avoid metal tools that could scratch the surface

- Peel gently from the edge; do not force removal

- Use adhesive remover compatible with polycarbonate if residue remains

FR 700 vs. Polyester Film Tape: A Performance Comparison

| Property | FR 700 Polycarbonate Film Tape | Polyester Film Tape |

|---|---|---|

| Flame Rating | UL94 V-0 – high flame resistance | Typically no flame rating or VTM-0 |

| Heat Resistance | High – retains shape and strength at elevated temperatures | Moderate – may shrink or deform under heat |

| Surface Appearance | Dual-finish: matte + velvet | Glossy or matte; single texture |

| Shielding Compatibility | Excellent with foil lamination | Limited compatibility |

| Mechanical Strength | High tear, impact, and puncture resistance | Lower durability in rugged conditions |

| Insulation Reliability | Superior for electronics and power supply | Suitable for basic insulation tasks |

Final Thoughts: Choosing the Right Film Tape for Industrial Insulation

If your project involves high temperatures, electrical insulation, or EMI shielding, polycarbonate film tapes are the superior choice. While polyester film tapes are common and cost-effective, they often fall short in extreme conditions.

When performance, fire safety, and durability are critical, a high-grade polycarbonate solution provides long-term reliability across diverse industrial environments.

For advanced insulation performance, precise engineering, and uncompromising safety, choose FR 700 by Fonitaniya—the polycarbonate film tape trusted by professionals worldwide.